Procedure

The holding brake requires a typical voltage of 24 V ±10%. Proceed as follows to determine the

input voltage of the Motor Module that matches the holding brake:

1. Take the holding brake voltage and its tolerance from the motor technical data.

– Take into account possible voltage drops in the Motor Module and along the supply cable.

Use a Control Supply Module or a controlled DC power supply whose setpoint is set to at

least 26V.

– Note that there are holding brakes that close again when the maximum voltage is

exceeded.

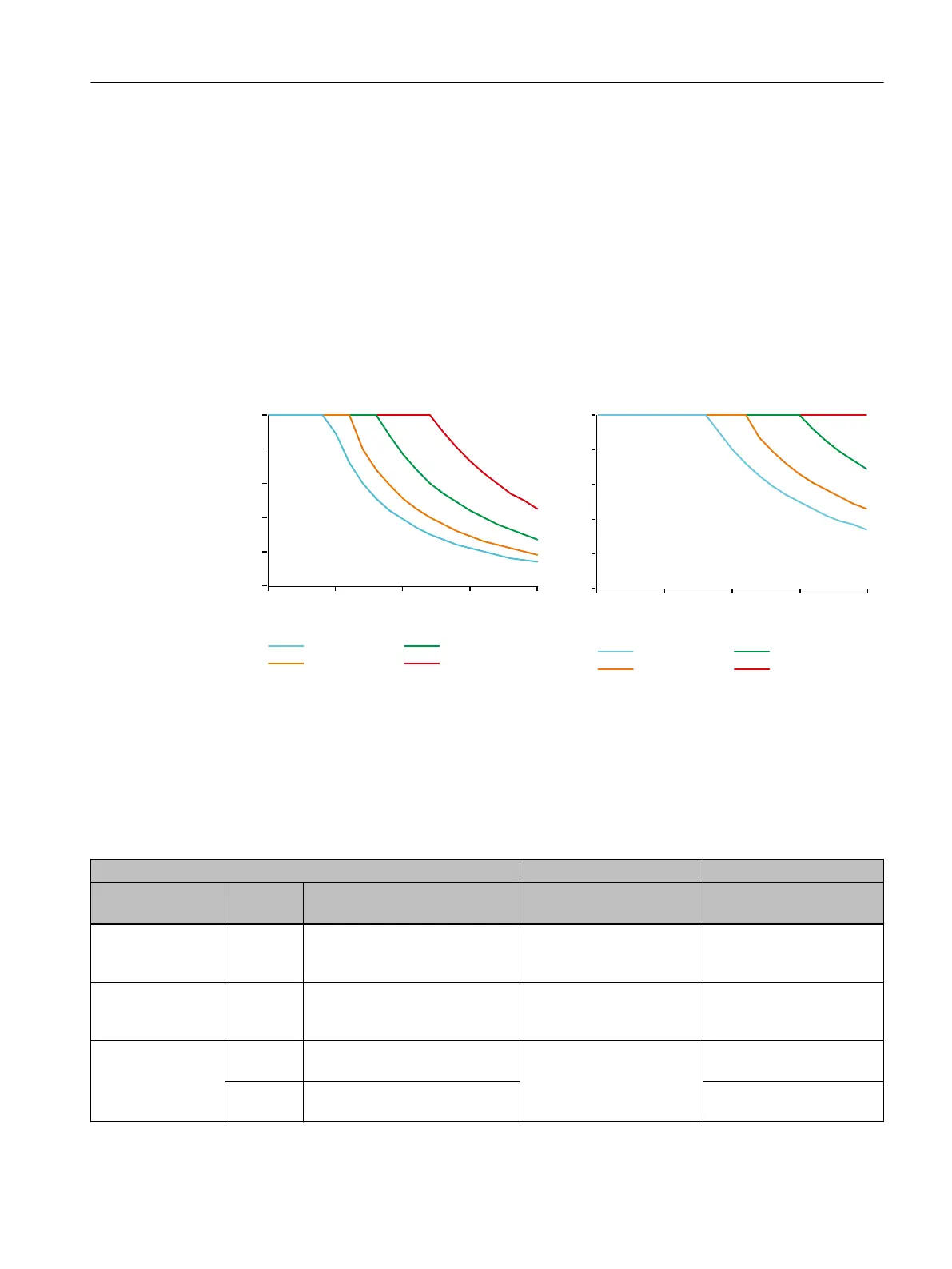

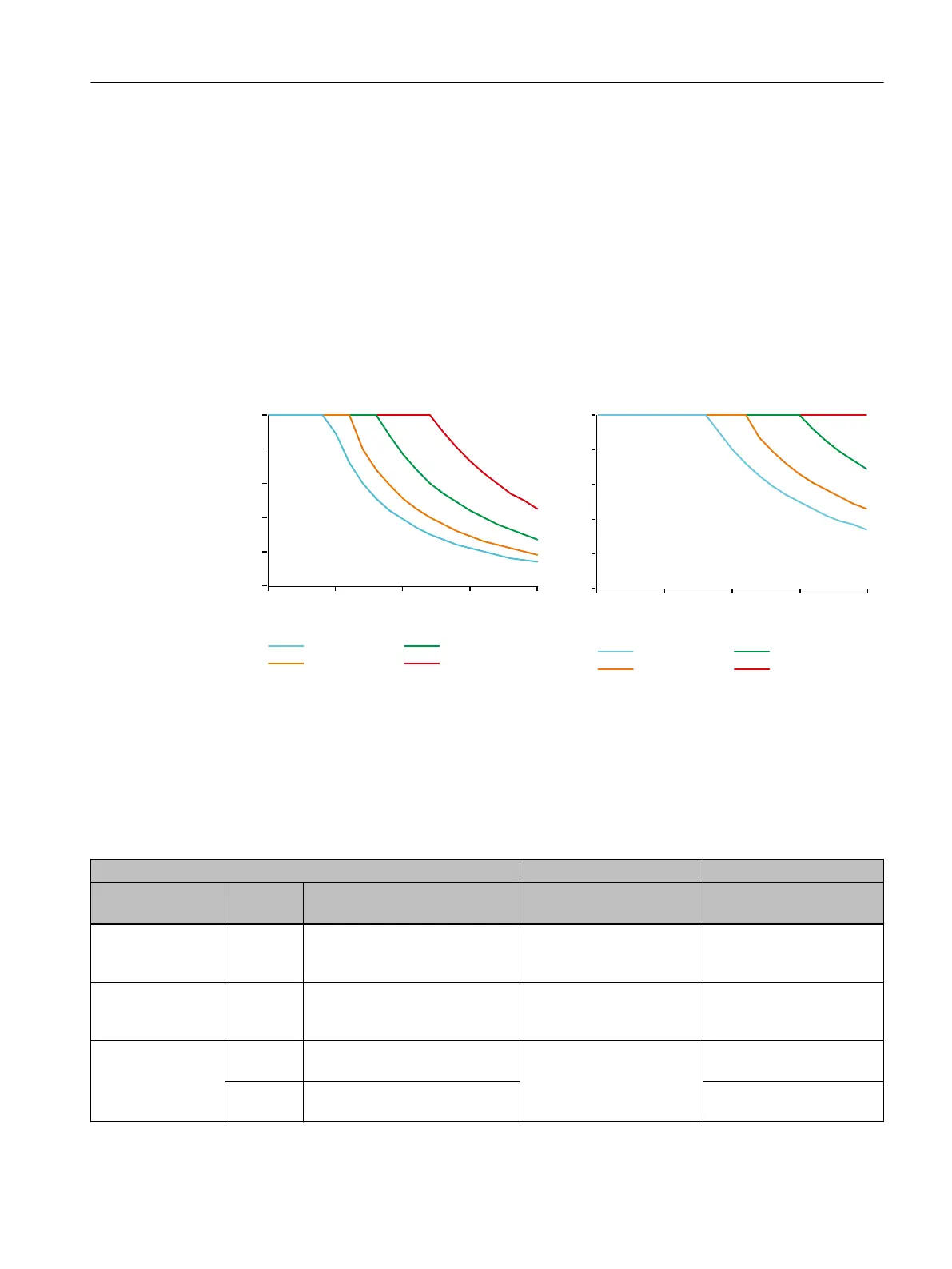

2. Check the permissible cable length using the following diagrams.

)PMEJOHCSBLFDVSSFOU<">

$BCMFMFOHUI<N>

PPt

PPt

PPt

PPt

24 V input voltage

$BCMFMFOHUI<N>

)PMEJOHCSBLFDVSSFOU<">

PPt

PPt

PPt

PPt

26 V input voltage

4.10.3 Selecting power supply units

The following devices meet the applicable requirements of EN 60204-1 and they are

recommended:

Recommended power supplies: SITOP Power modular

Rated output cur‐

rent [A]

Phases Rated input voltage [V]

Operating voltage range [V]

Short-circuit current [A] Article number

5 1/ 2 AC 120 … 230/230 … 500

85 … 264/176 … 550

approx. 5.5(running up)

typ. 15 for 25 ms (in opera‐

tion)

6EP1333-3BA00-8AC0

10 1/ 2 AC 120 … 230/230 … 500

85 … 264/176 … 550

approx. 12(running up)

typ. 30 for 25 ms (in opera‐

tion)

6EP1334-3BA00-8AB0

20 1/ 2 AC 120 / 230

85 … 132/176 … 264

approx. 23(running up)

typ. 60 for 25 ms (in opera‐

tion)

6EP1336-3BA00-8AA0

3 3AC 230/400… 288/500

320… 550

6EP1436-3BA00-8AA0

Application planning

4.1024 V DC supply voltage

Booksize power units

Equipment Manual, 09/2023, A5E53307519B AA 49

Loading...

Loading...