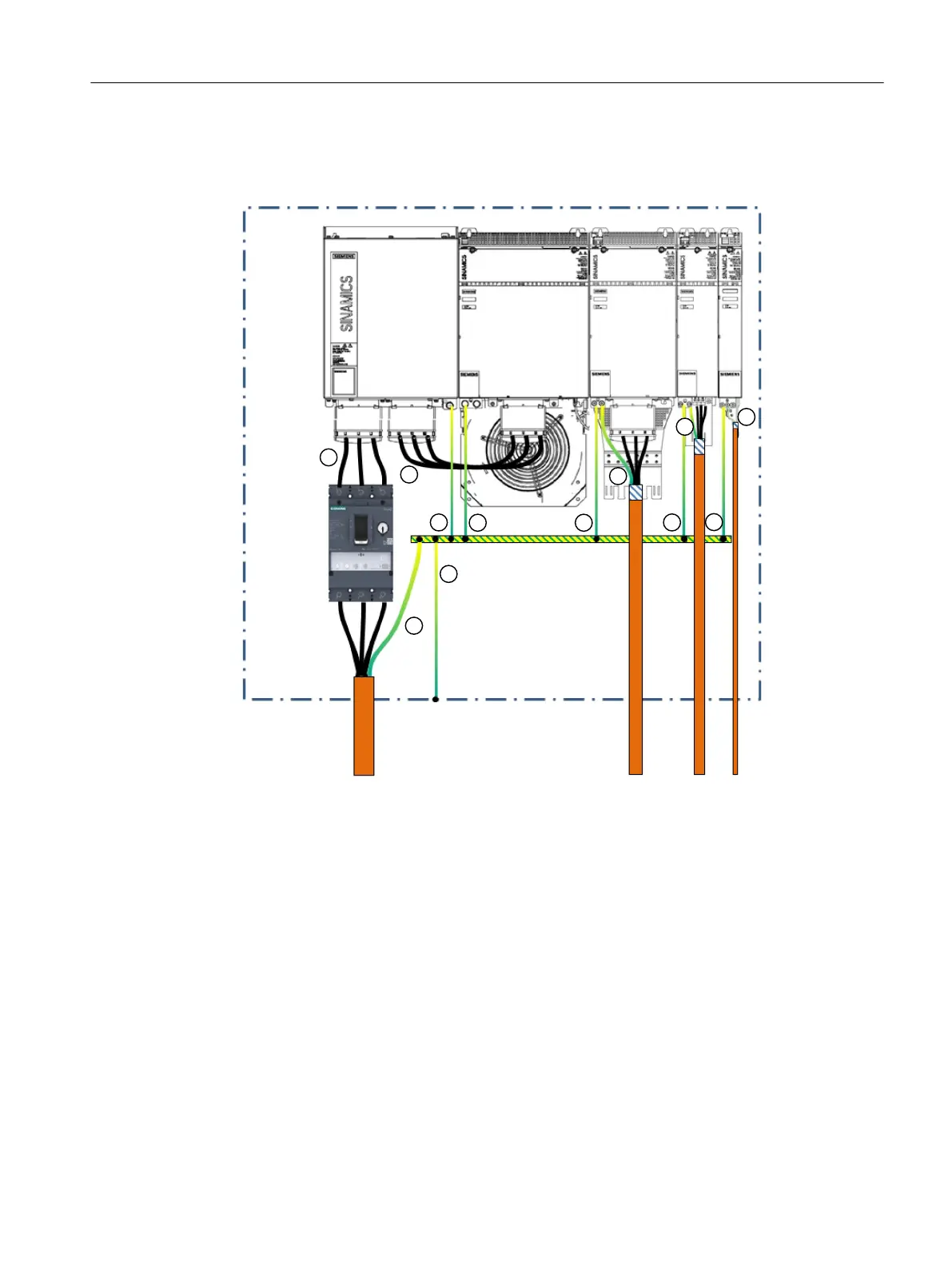

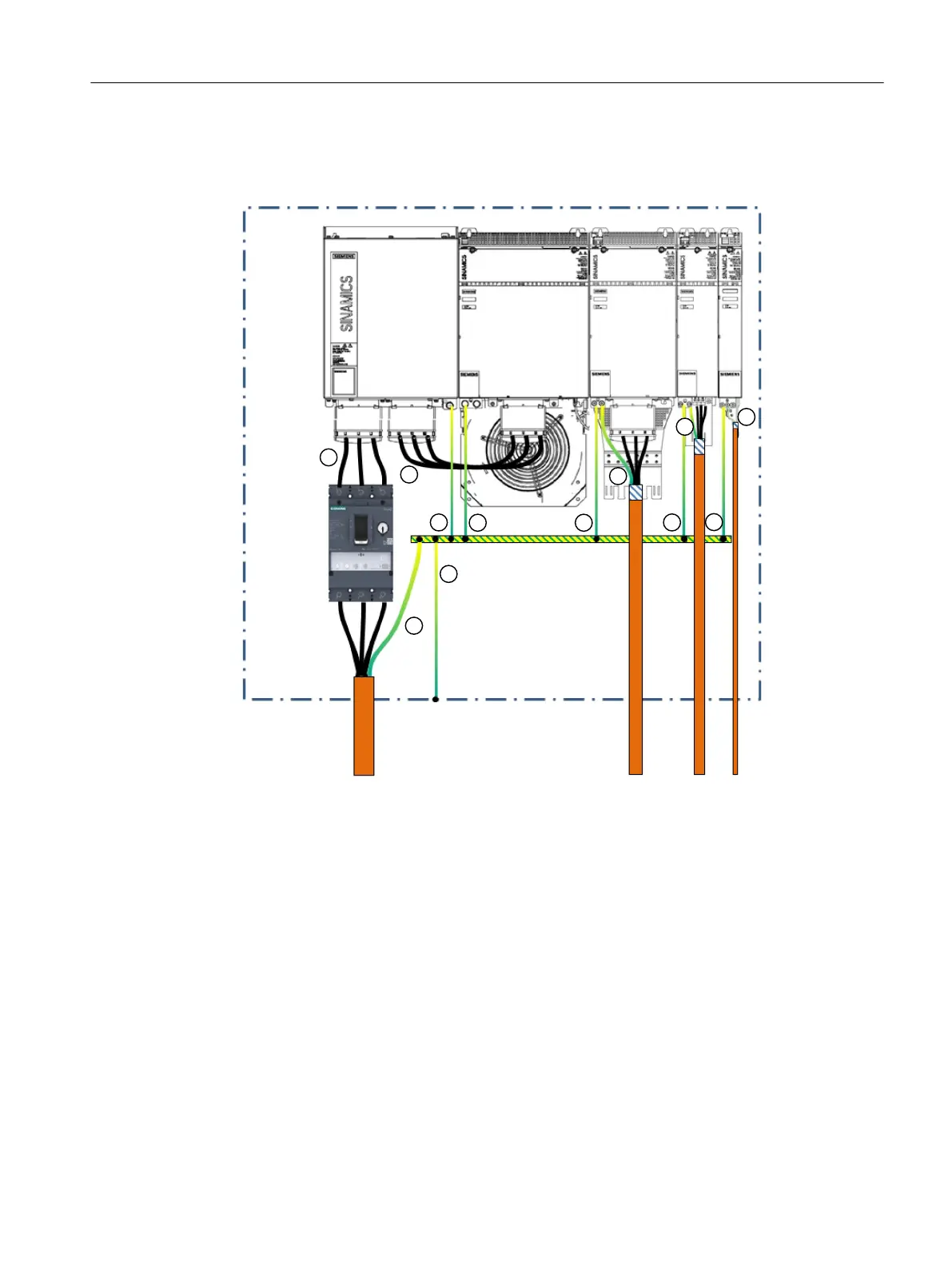

Overview diagram

The following diagram shows the protective connection concept for the drive line-up.

3(UDLO

2YHUFXUUHQW

SURWHFWLRQ

GHYLFH

&RQWUROFDELQHW

0RWRUFDEOHV/LQHVXSSO\

FDEOH

$FWLYH/LQH0RGXOH$FWLYH,QWHUIDFH0RGXOH0RWRU0RGXOHV

① The protective conductor (PE) must be dimensioned in compliance with local installation rules for

equipment with increased leakage currents. As a minimum, it must satisfy one of the following

conditions:

• The protective conductor is routed so that along its complete length it is protected against

mechanical damage.

• The protective conductor has a cross-section ≥10mm

2

Cu.

• A second protective conductor with the same cross-section is provided.

• When establishing the connection using an industrial plug connector according to EN 60309,

as core of a multi-core cable it has a cross-section ≥2.5mm

2

Cu.

• As a core of a multi-core cable, the protective conductor has a cross-section ≥2.5mm

2

Cu.

② The cable cross-section must be dimensioned in compliance with local installation rules.

③ The cable cross-sections must be dimensioned in compliance with local installation regulations.

④ The protective conductor must have the same cross-section as the line conductor of the motor

connection cable.

Application planning

4.15Protective connection and function equipotential bonding

Booksize power units

Equipment Manual, 09/2023, A5E53307519B AA 71

Loading...

Loading...