Procedure

Proceed as follows to calculate the current load of the DC link busbars:

1. Add the DC link currents I

DC link

of the connected Motor Modules. The DC link current values

are listed in the technical data of the Motor Modules.

2. Check whether the continuous current-carrying capacity of the DC link busbars is exceeded.

– The maximum current-carrying capacity of the DC link busbars dier for the various

components. You can take the values from the following table:

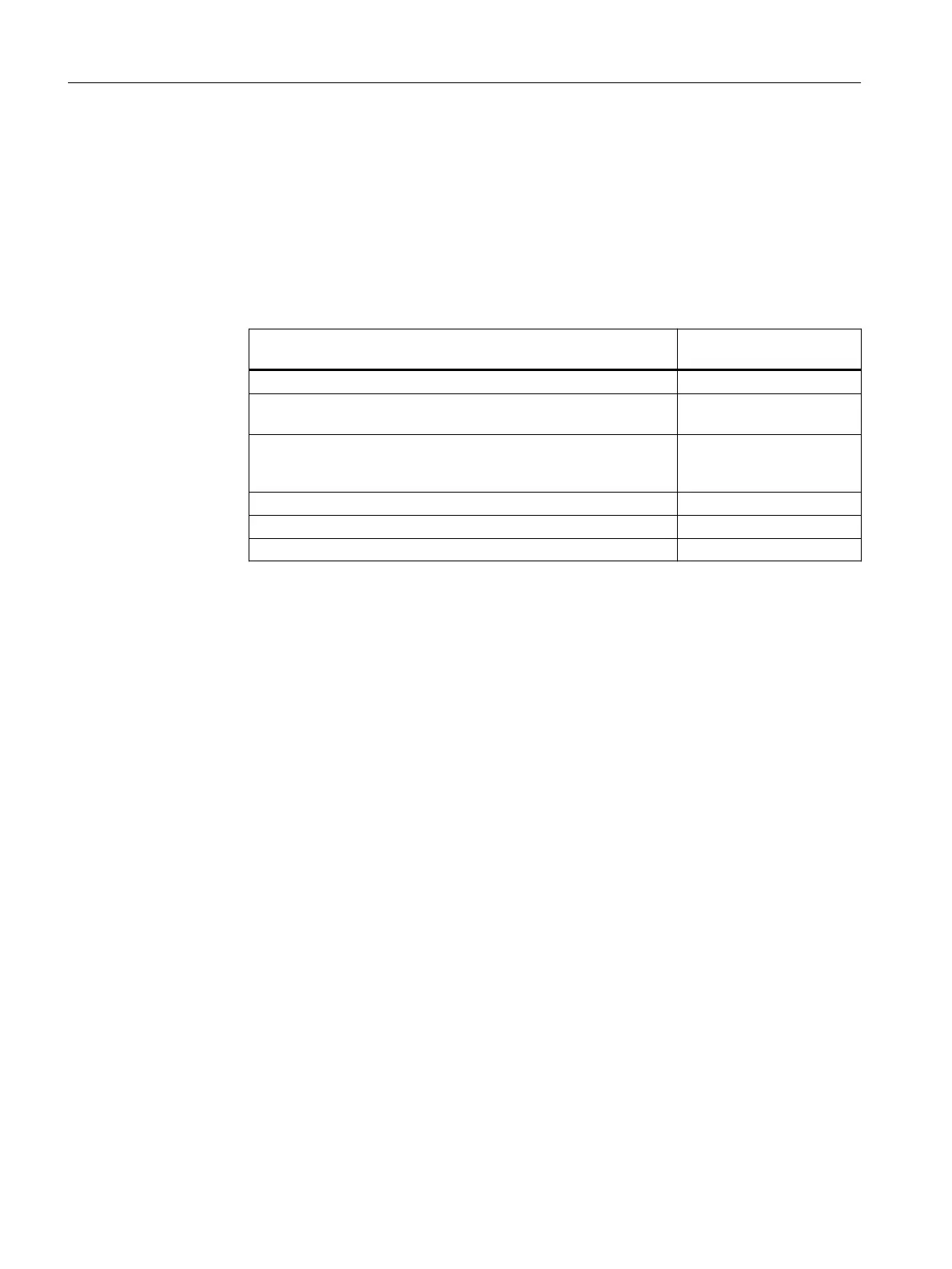

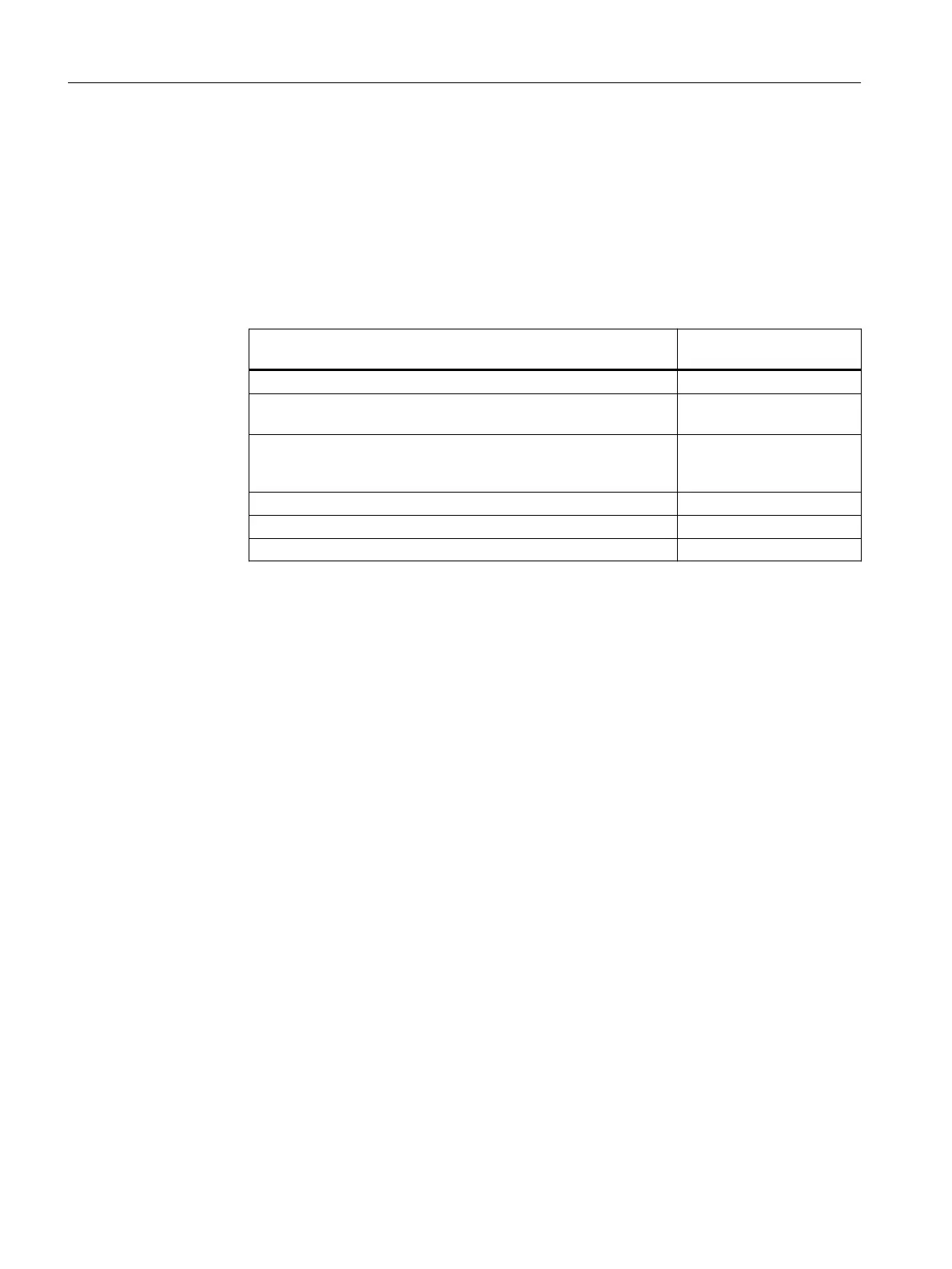

DC link busbar or bridge Continuous current-carry‐

ing capacity [A]

1)

Smart Line Modules 100mm 200

Motor Modules 50mm

with 4mm DC link bridges

100

Motor Modules 50mm

with 6mm DC link bridges

(Article No. 6SL3162-2BB00-0AA0)

200

Motor Modules 100mm 200

Motor Modules 150mm - 200mm 250

DC link components 100

1)

The continuous current-carrying capacity specied here applies to an ambient temperature of

up to 40°C. From

40°C to 55°C, the continuous current-carrying capacity is reduced by 2.67% per °C.

For the planned conguration, if the current load to be assumed exceeds the continuous

current-carrying capacity of the DC link busbars, then the following solution is available to

congure the drive line-up:

• Center infeed: Conguration with infeed at the center and the Motor Modules and DC link

components mounted to the left and right

Mounting

5.2Layout of the components

Booksize power units

80 Equipment Manual, 09/2023, A5E53307519B AA

Loading...

Loading...