VA Motion Controller Programming Manual

436

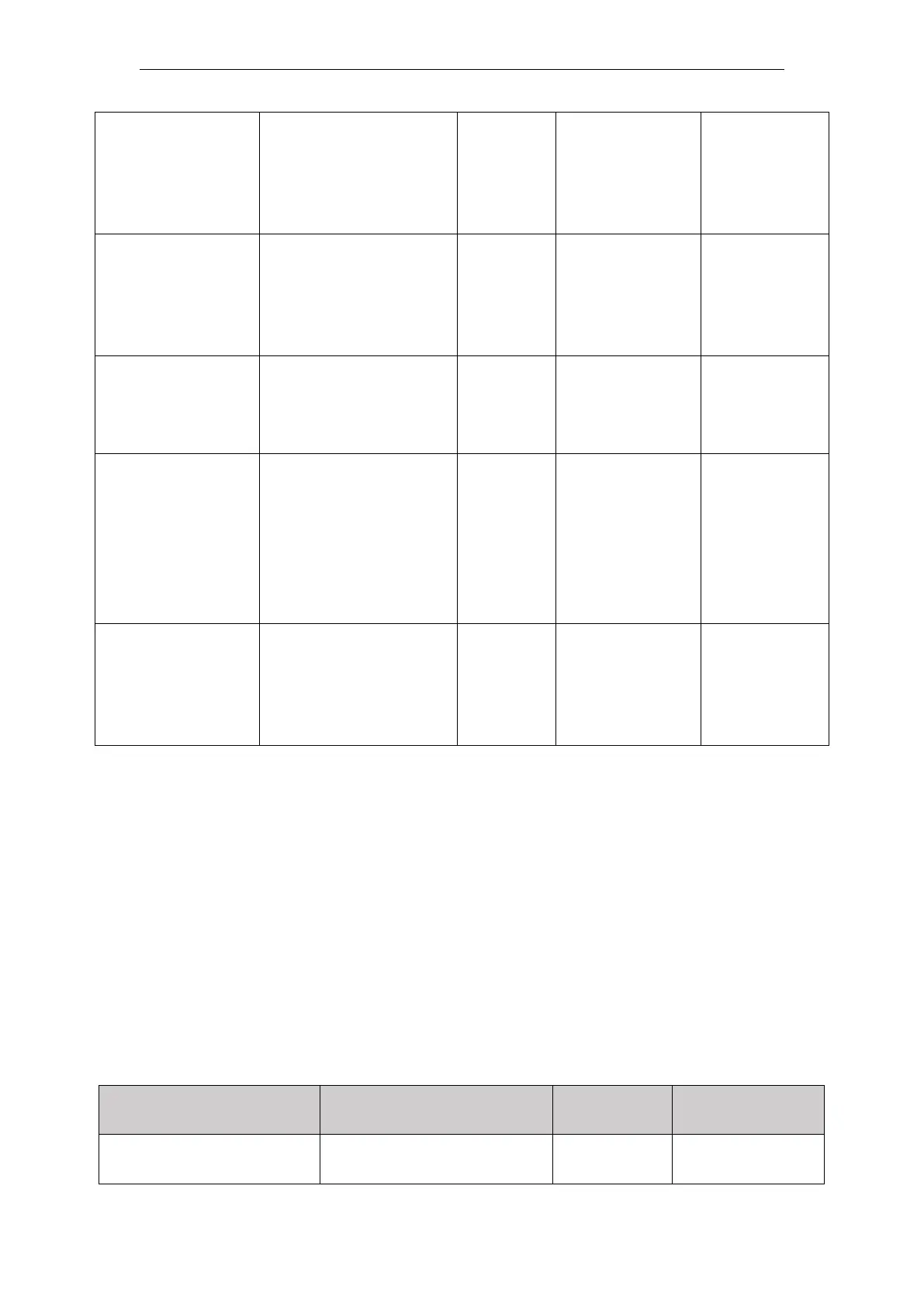

Value of 0 to 7

corresponding to the input

point I0.0 ~ I0.7,8 ~ 15

corresponding to the input

I1.0 ~ I1.7

Mark_DI_Edge

(Color signal

edge punctuation)

Punctuation set color

signal trigger edge

along

0: Falling

1: Rising

Exexcute

from FALSE to

TRUE

Cut_DI_Valid

(Cut point signal

valid bit)

Status is TRUE

effective cut point signal;

FALSE cutting point signal

is invalid;

Exexcute

from FALSE to

TRUE

Cut_DI_Num

(Cut point signal)

Cutting bit number

designated terminal, the

input value of 0 to 7

corresponding to the input

point I0.0 ~ I0.7,8 ~ 15

corresponding to the input

I1.0 ~ I1.7

Exexcute

from FALSE to

TRUE

Cut_DI_Edge

(Cutting edge

point signal)

Cutting edge set-point

signal trigger

along

0: Falling

1: Rising

Exexcute

from FALSE to

TRUE

Description:

For Disc_Circumference peeling axis and the feed axis, set FeedAxisRadius (feed shaft

radius), RotaryAxisRadius (peeling axis radius) before, should their respective axis parameter

module MC_AXIS_REF, set their respective radii match (circle circumference of the disc)

parameters for use in MC_ReadActualPosition, MC_ReadActualVelocity module.

When the instruction is being executed may be modified CutLength, after re-trigger value

Execute SyncAngle, FeedAxisRadius, RotaryAxisRaidus, RotaryAxisKnifeNum,

First_Mark_Offset, Mark_DI_Valid, Cut_DI_Valid, the modified parameters to take effect in

the next cycle after the trigger cam Execute. Execute and do not re-trigger CommandAborted

set to TRUE;

The CANopen mode, or the tangent point with color function is not available.

Output parameters

InSync (synchronized

state)

This parameter is TRUE

output shaft from the

Loading...

Loading...