74Service Manual – CS7010™ 14 - Wheel System, Non-Traction

Troubleshooting

Problem Cause Correction

Thewheelsare

makingexcessnoise.

Thewheelbearingsworn. Checkthewheel,wheelbearings,andbrakeand

spindle assembly and replace as required.

Thewheeland/orbrakeand

spindle assembly are damaged.

Thebrakesarenot

workingcorrectly.

Thebrakesareoutofadjustment Adjustthebrakes.

Thebrakeliningsarewornout. Replacethebrakelinings.

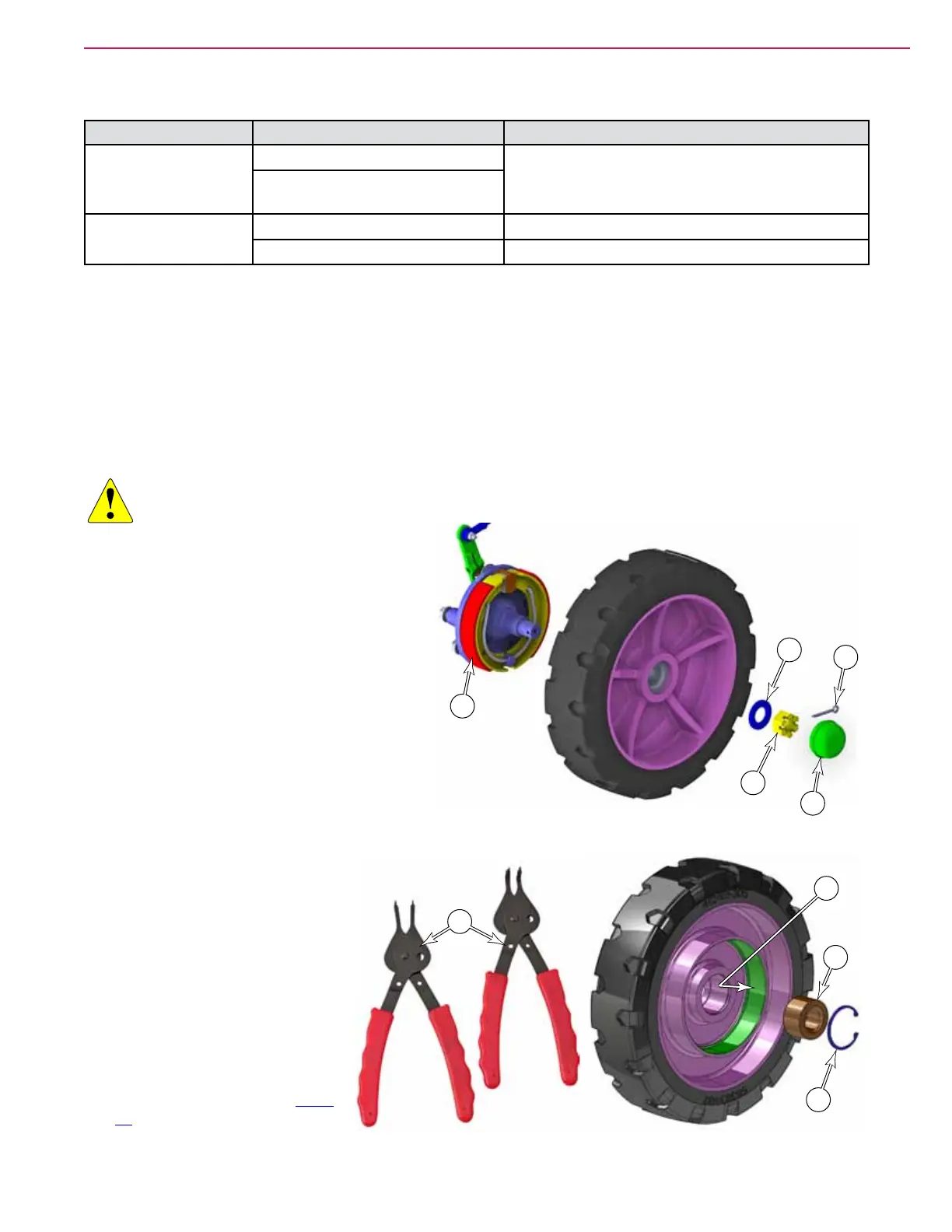

Removal and Installation

Wheel

Wheel Bearing

Regardless whether the procedure is being completed to replace a wheel versus a bearing, both right and

left sides should be completed together. Replacing only 1 wheel can result in adverse brake wear if the brake

drums are not equal.

WARNING: Never work under a machine without safety stands or blocks to support the machine.

When jacking the machine, do so at the designated tie down/jacking locations.

1. Jack the front of the machine enough

to raise the front wheels slightly off the

ground, and place jack stands under the

machine for safety.

2. Using a sharp-edged tool, carefully work

the dust cap (A) loose from the wheel. Take

care not to damage or deform the cap.

3. Remove the cotter pin (B) from the castle

nut (C), and remove the nut, washer (D),

and wheel from the axle spindle.

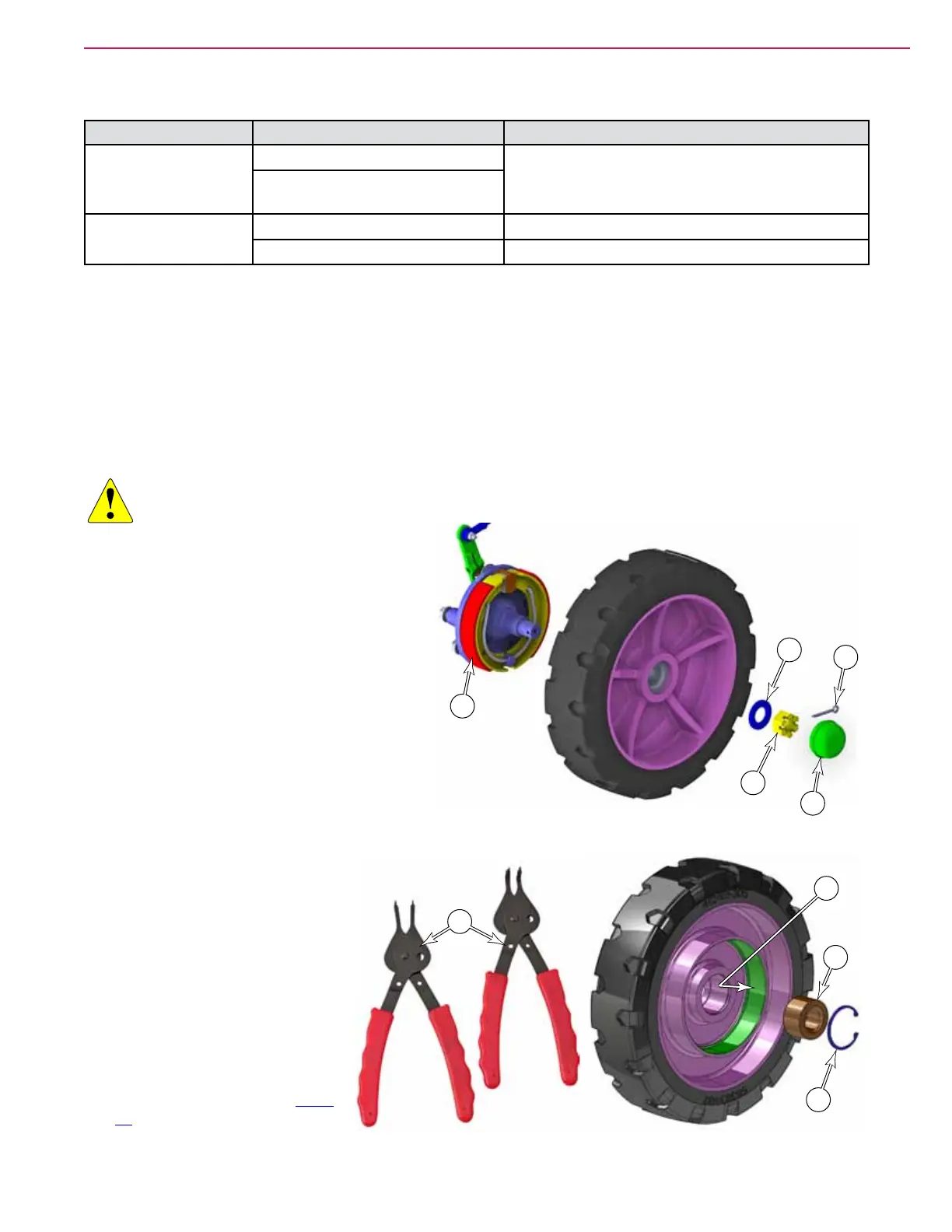

4. Using a retaining ring pliers (J), remove

the retaining ring (E) from the wheel hub,

and remove the bearing (F).

5. Before replacing the wheel,

inspect the brake linings (H)

and the drum surface (G) for

excessive wear.

6. During replacement, tighten

the castle nut (C) enough to be

slightly snug, and then continue

turning enough to insert the

cotter pin (B) through the shaft.

7. If the wheels have been

replaced, inspect the Brake

adjustment described on page

73

A

B

C

D

H

F

E

G

J

Loading...

Loading...