22Service Manual – CS7010™ 03 - General Information

Maintenance

Maintenance Schedule

Keep the machine in top condition by closely following the maintenance schedule. Maintenance intervals

given are for average operating conditions. Machines used in severe environments may require service more

often. In general:

• Keep the fuel tank lled (diesel). This helps to reduce condensation and moisture entering the fuel

system.

• Be aware of the yellow Attention Indicator light, the red Warning Indicator light and the OLED Display

on the Operator panel for icons and fault codes that indicate a critical or non-critical fault condition.

• Refer to the engine service manual for recommended engine service intervals and procedures.

Recommended Service Materials

• Engine Oil (refer to your engine manual)

• Manufacturer-recommended coolant (antifreeze) 50/50 mix (LPG and diesel models only)

• Lithium-base grease

• Loctite® (or equivalent) thread sealant in the appropriate grades

• Never-Seez® (or equivalent) anti-seize compound

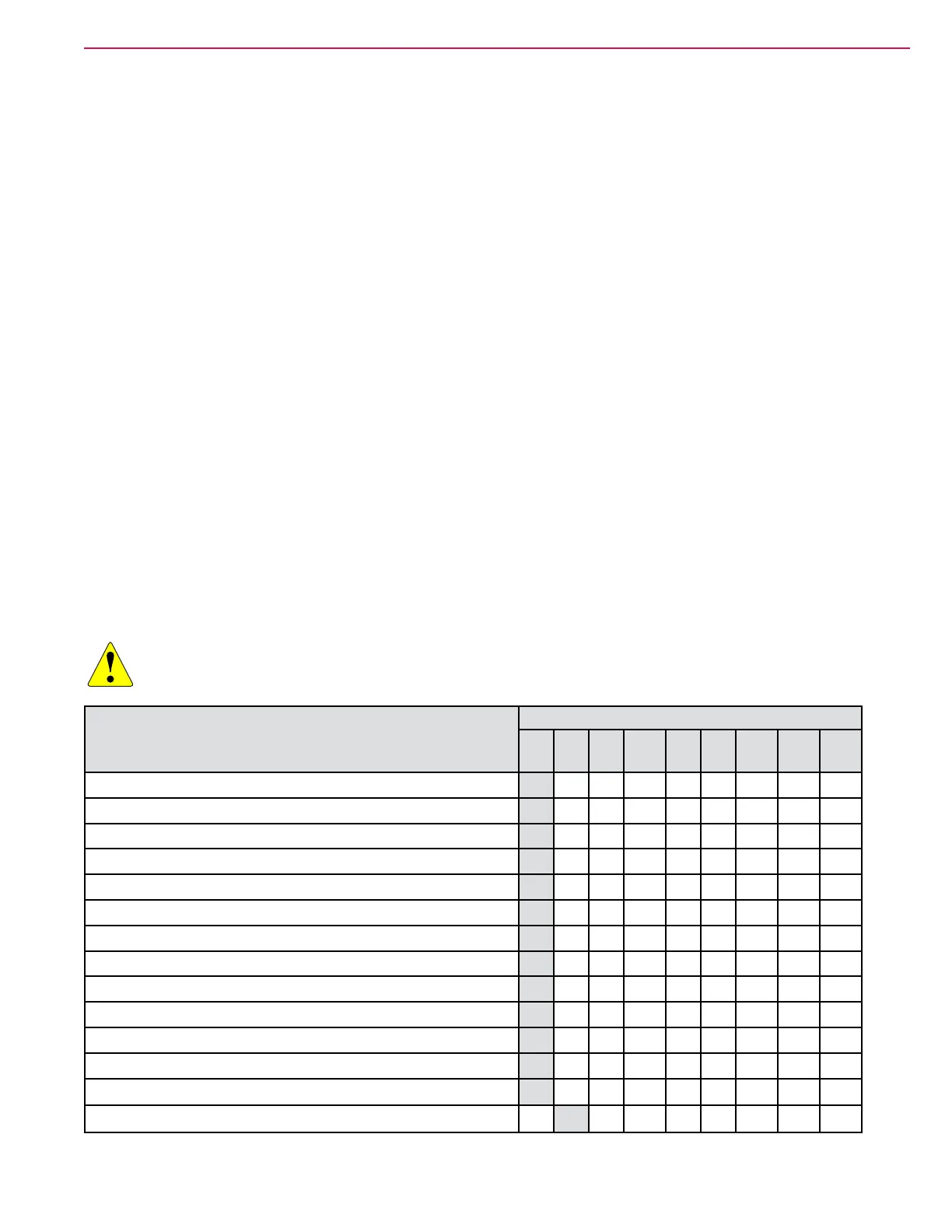

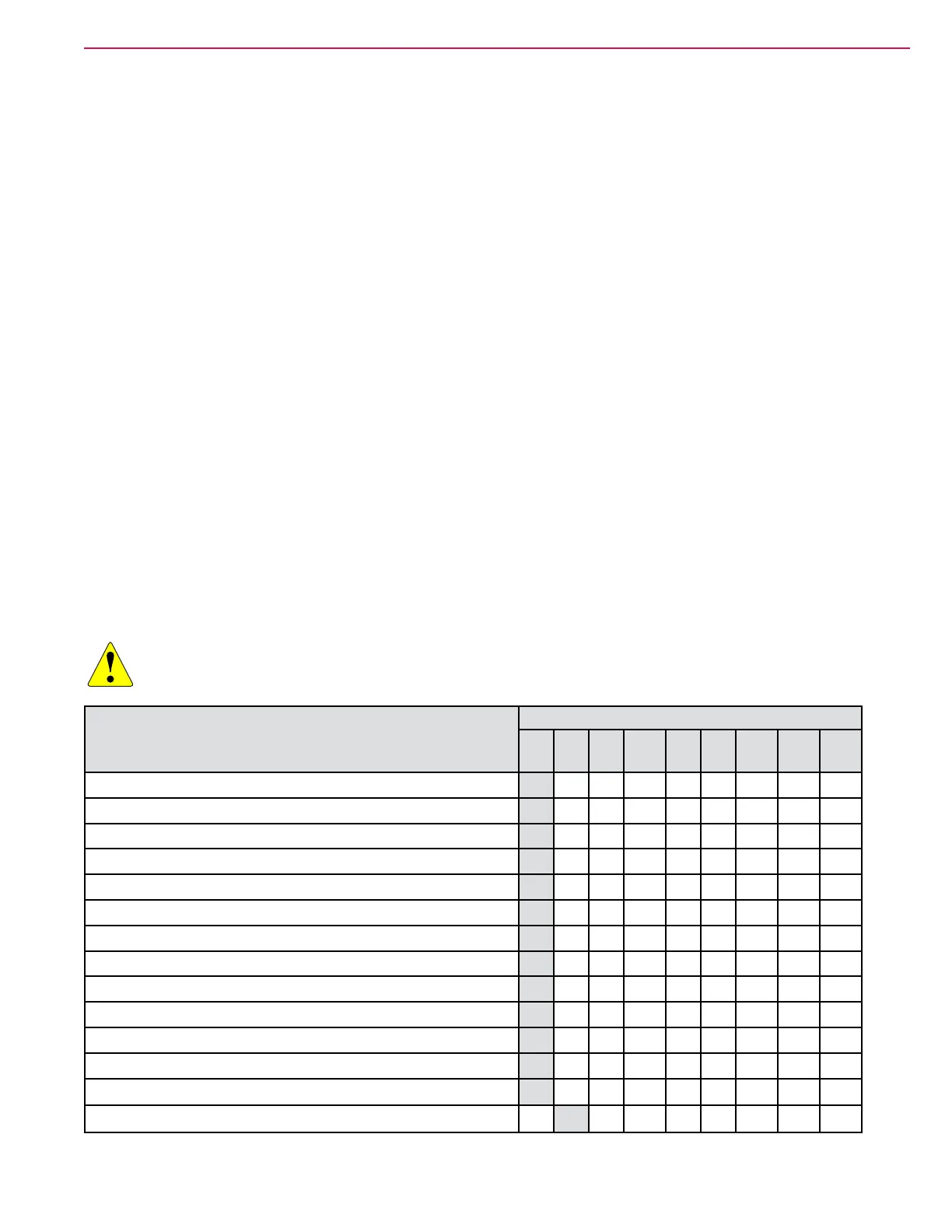

Routine Maintenance

CAUTION: Do not pressure-wash the operator control panel, fuse panel, contactor panel or engine

compartment area.

Maintenance Item

Interval

Day Wk Mo 15-20

Hrs

150

Hrs

400

Hrs

1000

Hrs

1500

Hrs

2000

Hrs

Charge battery (battery models)

X

Check parking brake

X

Check engine oil (engine models only)

X

Check engine coolant level (engine models only)

X

Check air lter service indicator

X

Clean main and side brooms

X

Check and clean the scrub brushes

X

Drain / Check / Clean Tanks & Hoses

X

Clean recovery tank Debris Basket (51)

X

Check / Clean / Adjust the squeegee

X

Clean the hopper

X

Clean / Inspect scrub deck side skirts

X

Check/Clean/Rinse vacuum motor foam lter and screen

X

Check hydraulic oil level

X

Loading...

Loading...