77Service Manual – CS7010™ 20 - Wheel System, Traction

Drive Pedal Potentiometer

The drive pedal potentiometer is a variable resistor connected to the Pin J5--20 input of the drive controller,

with pins J5--31 and J5--32 as reference voltages. As the resistance changes, the drive controller increases or

decreases drive motor speed.

The drive pedal is set up in what’s called a wig-wag conguration, where drive direction is controlled by

a single potentiometer. When the throttle potentiometer is in the center position, the wiper voltage is

approximately 2.8 volts. The speed controller interprets any voltage between 2.3V and 3.3V as neutral

and the output to the motor will be zero. Forward or Reverse movement of the drive pedal rotates the

potentiometer shaft and the wiper voltage is increased for forward travel, or decreased for reverse travel.

The magnitude of the voltage difference away from the neutral point also determines the speed that the

motor will be driven.

To allow for minor variation in the pedal returning to the neutral position, the drive controller establishes

a deadband around the 2.8-volt center. This results in a plus/minus range of voltages where the controller

assumes the pedal is still in the neutral position. The deadband for this drive controller (2.3 to 3.3 V) is set

in the machine’s rmware, and is not adjustable.

Drive Controller

The drive motor is controlled from an InMotion AC Superdrive

controller, which is an AC induction motor controller for battery

operated equipment. The controller generates a square wave,

3-phase, pulse-width-modulated output to the motor. The speed

controller is designed specically for DC motors with remote

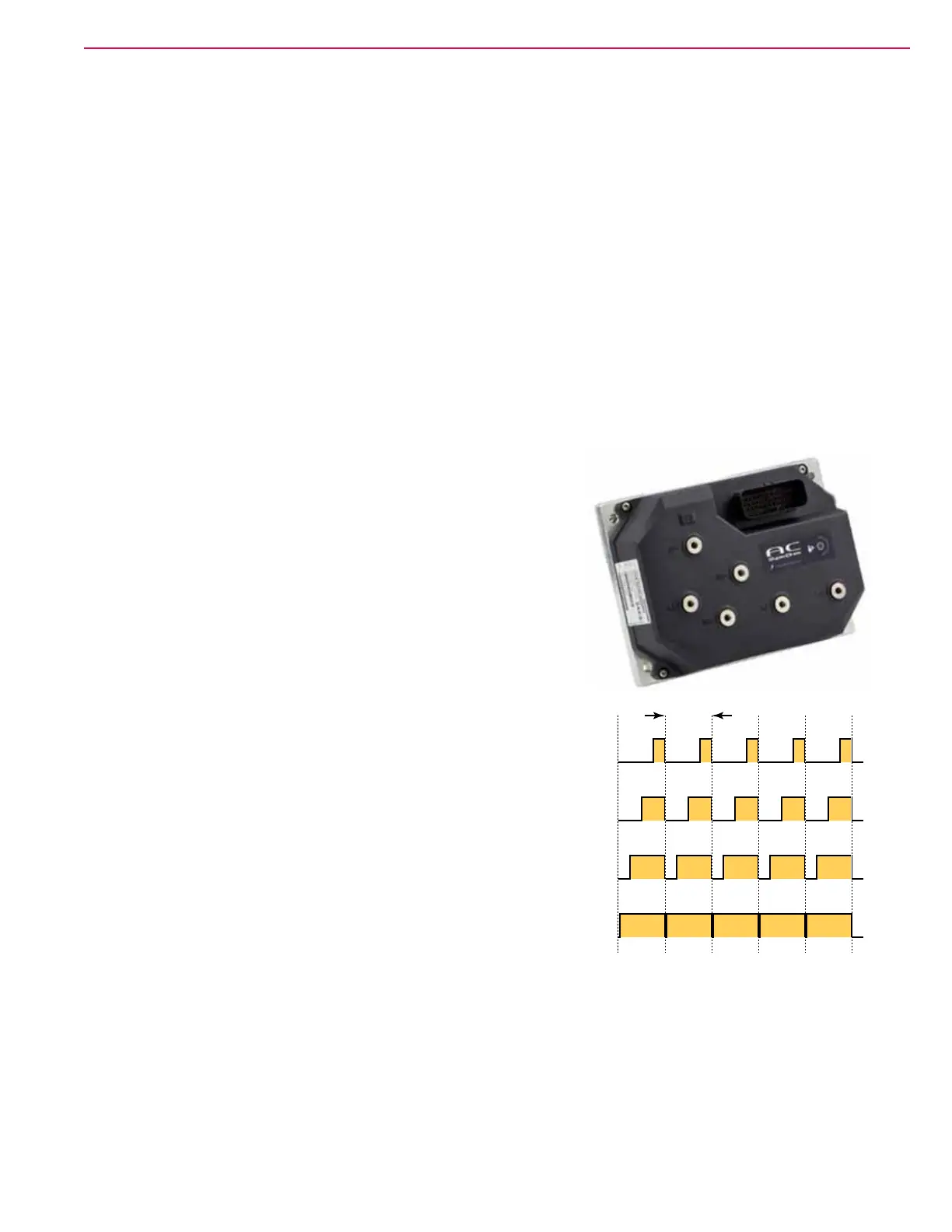

commutation. Pulse-width-modulation (PWM) is a form of motor

speed control that alters the power to a motor by rapidly turning

the power on and off. The ratio (also called “duty cycle”) between the

On and Off states determines how much power the motor receives.

The shorter the “off-time” the closer to full power the motor will

receive. This switching occurs so fast (between 4 and 16kHz for this

controller) that the motor simply sees it as a reduction in power

(voltage) instead of the rapid on/off. PWM is a standard motor

control technique because it is easier to turn power all the way on and all

the way off, than it is to vary the magnitude of the power. Varying the

magnitude would create a lot of heat that would need to be dissipated.

Another unique aspect of the drive controller compared to other PWM

motor controllers in the system, is that the wheel drive motor requires

remote commutation. Mechanical commutation happens with motor

brushes in other motors. For remote commutation, the controller needs

to know what the actual internal rotational position of the rotor is inside

the motor.

The drive motor contains a pair of encoders that tell the drive controller

what the rotational position is of the rotor. The drive controller uses this

information to determine which phase outputs should be energized.

25% PWM Duty Cycle

50% PWM Duty Cycle

75% PWM Duty Cycle

100% PWM Duty Cycle

1-Cycle

(15kHz)

Loading...

Loading...