In the example depicted in Illustration 5.29, the real-time

task sampling is 8 kHz (125 µs between 2 samples), the

fast task sampling is 4 kHz (250 µs between 2 samples),

and the slow task sampling is 2 kHz (500 µs between 2

samples). These sampling rates are also shown for oine

devices.

The Subsampling eld controls the subsampling level of

the trace, which is a factor applied to the sampling rate:

for example, using a fast task sampling with 250 µs

between 2 samples and subsampling 3, the resulting trace

has 750 µs between 2 samples.

The

eld Samples controls the length of the trace in terms

of the number of sample counts per channel. The

maximum number allowed depends on the trace buer of

the device and the number of channels to trace. For

example, if a device can trace a total maximum of 32000

samples and 4 channels are congured to be traced, then

the maximum number of samples per channel is 8000.

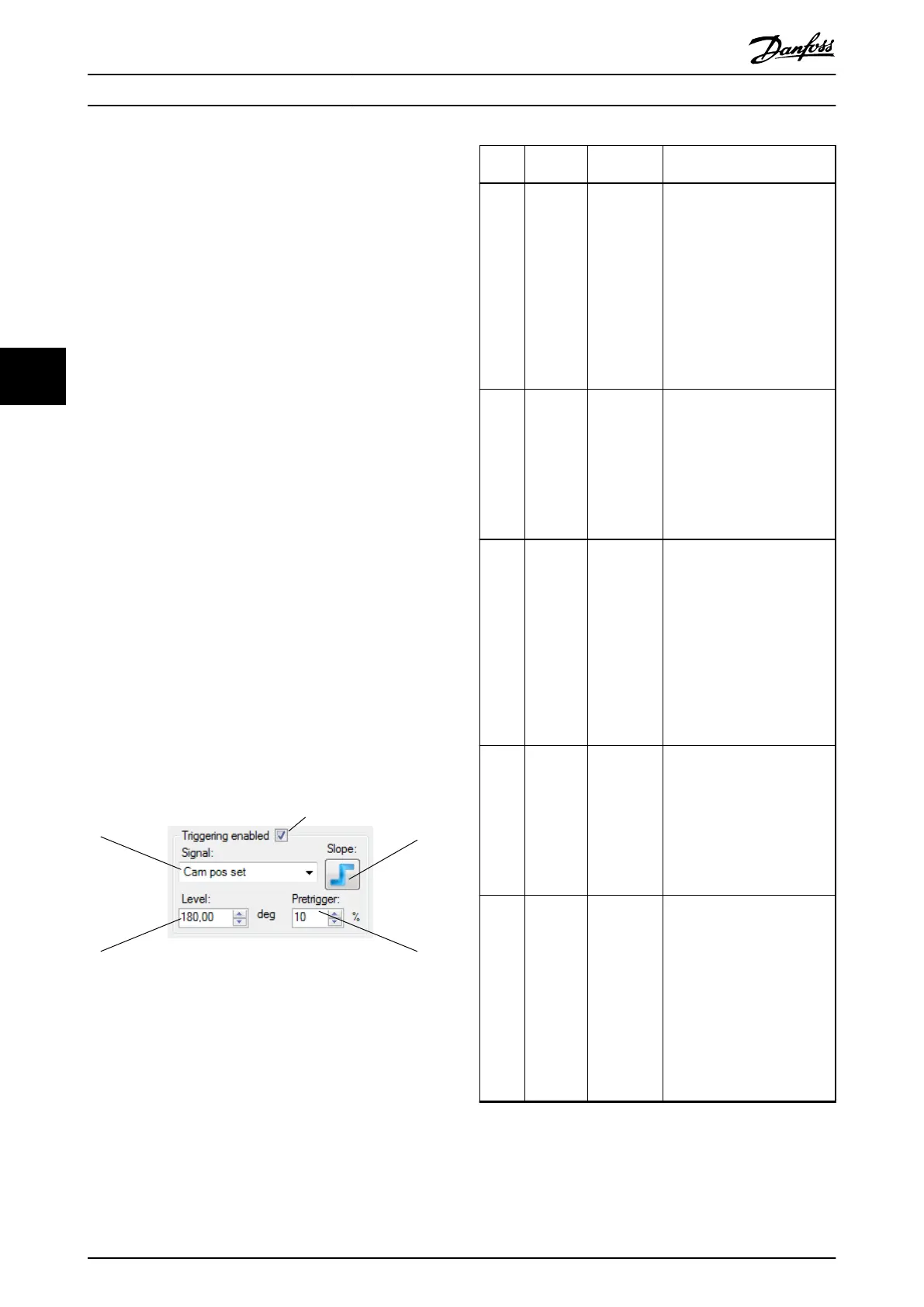

5.7.3.2 Triggering

The triggering functionality of the devices is visualized by

the Triggering control on the left side of the Scope. Specify

here whether the trace should be triggered by a certain

event, or if the trace should be started instantly.

Due to its real-time nature, the triggering functionality is

entirely implemented on the devices – the Scope only

controls and visualizes the triggering conguration on the

devices and does not implement any triggering logic.

A trigger event is dened by a trace signal, whose value is

exceeded in a positive or negative direction.

Illustration 5.30 shows an example of a trigger event that is

dened by the trace signal Cam pos set exceeding the

value of 180 degrees in a positive direction (rising slope).

Illustration 5.30 Triggering Control

Callout Field

name

Description Function

1 Signal Drop-down

list of

trigger

signals

Contains all available signals

on the device and selects the

signal to be used for

triggering. The behavior of the

Signal drop-down list is

exactly the same as the

behavior of the Signal name

drop-down list in the Signal

chooser control. It is not

necessary to also trace the

trigger signal.

2 Triggering

enabled

Checkbox to

enable/

disable

triggering

Controls whether triggering

should be used on the device.

If triggering is disabled, then

the trace is started instantly

after activation (pressing the

Run button). Also, all other

elds of the Triggering control

are disabled.

3 Slope Trigger

slope

Controls the direction from

which the Level value should

be reached in order for the

trace to be triggered: a rising

slope means that the value

should be reached in a

positive direction, and a falling

slope means that the value

should be reached in a

negative direction. The default

value of the button is rising.

4 Pretrigger Pretrigger Sets the number of samples to

be traced before the trigger

event occurs. The value is

given as a percentage of the

number of samples per

channel (eld Samples). The

default value of the eld is

10%.

5 Level Trigger level Shows the value at which the

trace should be triggered

(depending on the trigger

slope conguration). If

dened, the unit of the

selected trace signal is shown

on the right of the Level eld.

The trigger level eld is a

decimal value with 2 decimal

places. The default value of

the eld is 0.

Table 5.8 Legend to Illustration 5.30

Operation with ISD Toolbox

VLT

®

Integrated Servo Drive ISD

®

510 System

126 Danfoss A/S © 01/2017 All rights reserved. MG36D102

55

Loading...

Loading...