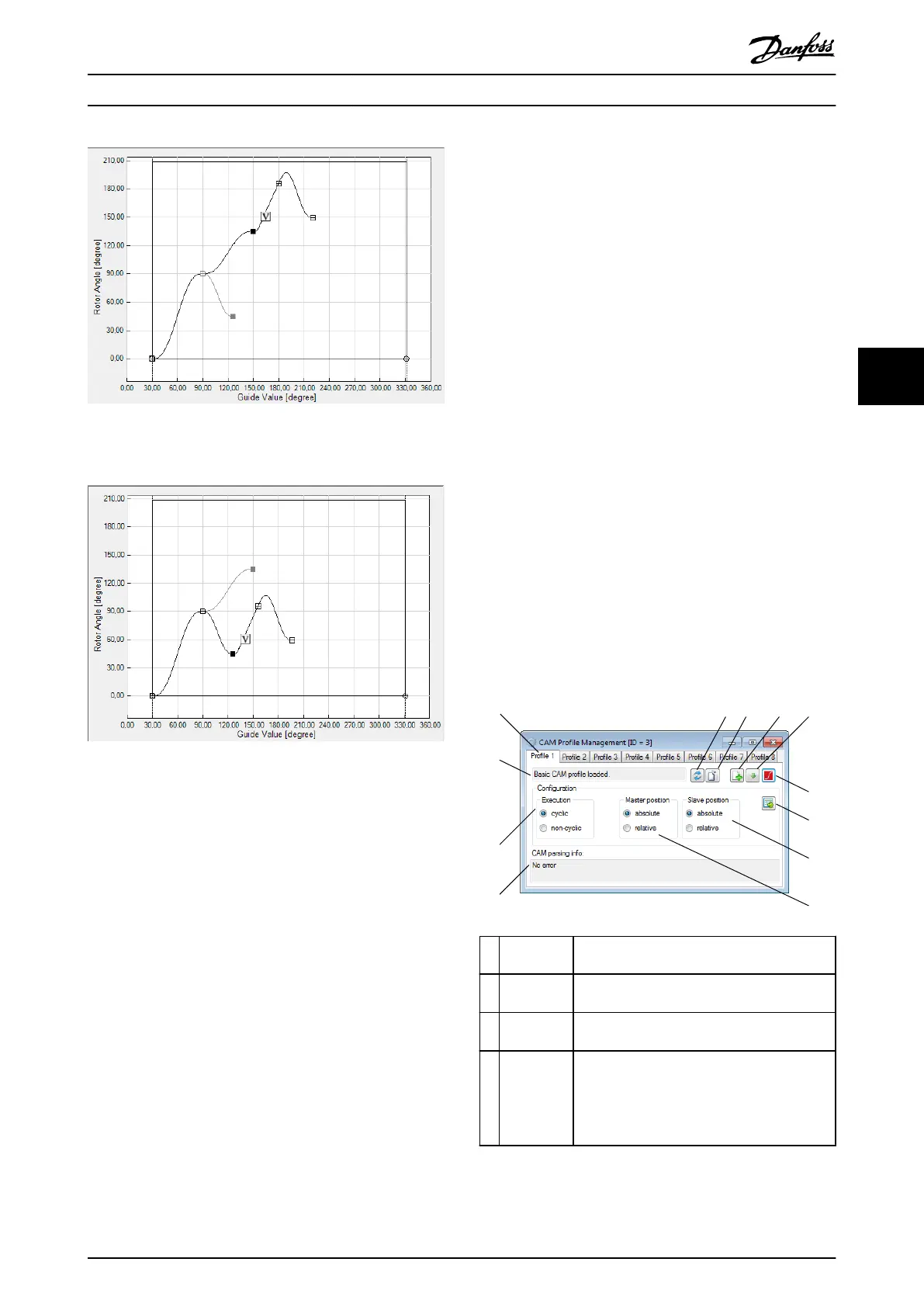

Illustration 5.82 Following Event Segments Depending on the

Selected Path 1

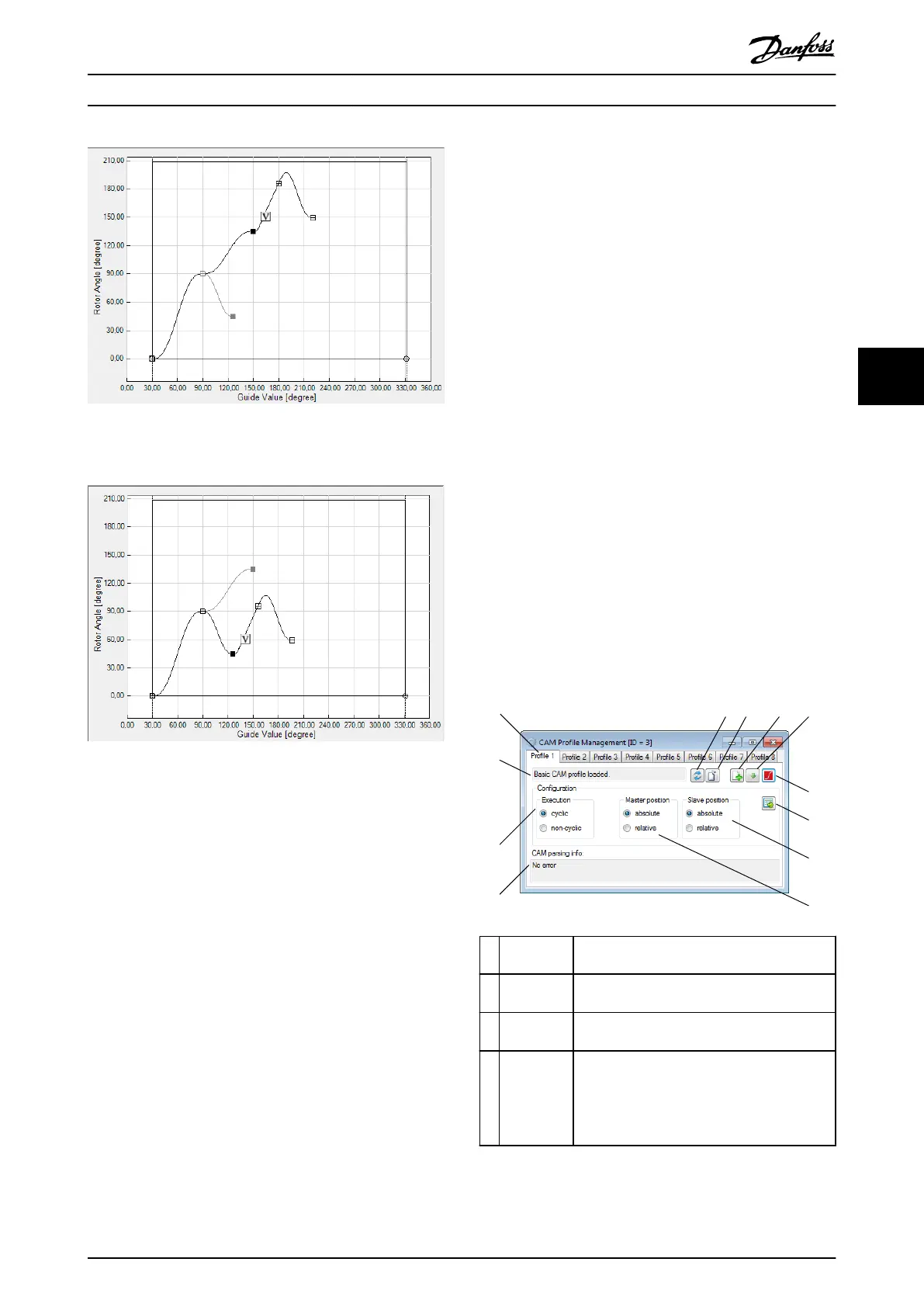

Illustration 5.83 Following Event Segments Depending on the

Selected Path 2

Sanity check

The Sanity check for advanced CAM proles helps to

identify potential problems and risks in a prole. The sanity

check identies and shows problems in 2 categories:

•

Warning: Shown to create awareness of certain

behavior.

•

Error: Prevent the export of the CAM prole.

The following situations result in a warning:

•

Jump in position: Shown whenever 2 succeeding

segments, connected by a node, dene dierent

End position and Start position.

•

Jump in velocity: Shown whenever 2 succeeding

segments, connected by a node, dene dierent

End velocity and Start velocity.

•

Jump in acceleration: Shown whenever 2

succeeding segments, connected by a node,

dene dierent End acceleration and Start

acceleration.

The following situations result in an error:

•

No data or incomplete data: <2 nodes or <1

segment have been specied in the CAM prole.

•

No starting node: No guide node with ID 0 is

specied in the CAM prole.

5.7.7.8 Standalone Emulation of the CAM

Editor

The ISD Toolbox is loaded and the CAM Editor is automat-

ically shown and maximized when a .cam or a .camproj is

double-clicked in Microsoft

®

Windows.

An

oine drive device is automatically added to the device

environment of the ISD Toolbox, rather than attempting to

connect to an existing physical device. Therefore, it cannot

be used to transfer CAM proles to a servo drive.

5.7.8 CAM Prole Management

There are multiple tasks for managing CAM proles on the

servo drive: sending CAM

prole les to the servo drive,

triggering the parsing procedure in the servo drive, and

conguring the proles. These tasks are done by using the

sub-tool CAM Prole Management. The CAM Prole

Management sub-tool contains a tab control with a

separate tab for every CAM prole slot on the servo drive

(1–8), see Illustration 5.84.

2

3 4

5

6

7

8

9

1

12

11

10

130BE821.10

1 Prole tabs

(1–8)

Provides information on the proles.

2 Refresh

button

Reads the state for the selected prole from

the servo drive and updates the user interface.

3 Parse

button

Triggers the parsing of the selected prole on

the servo drive.

4 Send File

button

Shows an Open File window for selecting

a .cam le and transmits it to the servo drive.

The parsing of the prole is not started

automatically and must be triggered by using

the Parse button.

Operation with ISD Toolbox Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 157

5 5

Loading...

Loading...