5 Get File

from Drive

button

If a .cam le exists for the selected prole, this

function transferss it from the servo drive and

shows a Save File window to select the location

to save the le to.

6 Open in

CAM Editor

button

If a .cam le exists for the selected prole, this

function transfers it from the servo drive to a

temporary location and opens it with the CAM

Editor.

7 Send

Congu-

ration

button

Sends the conguration (Execution, Master

Position, and Slave Position) to the servo drive.

8 Slave

Position

congu-

ration

Contains 2 radio buttons that specify if the

selected prole should be executed with slave

absolute or slave relative position. When the

sub-tool is opened, the option is read from the

servo drive and the radio buttons are selected

accordingly.

9 Master

Position

congu-

ration

Contains 2 radio buttons that specify if the

selected prole should be executed with

master absolute or master relative position.

When the sub-tool is opened, the option is

read from the servo drive and the radio

buttons are selected accordingly.

10 CAM Parsing

Info

Visualizes the download info and parsing info

for the selected prole index:

•

After a download procedure, shows its

result.

•

After a parse procedure on the servo drive,

shows text corresponding to the parsing

state status code on the servo drive.

•

When clicking on the Refresh button, the

ISD Toolbox reads the parsing state status

code from the servo drive and updates the

text.

•

When reading the CAM prole from the

servo drive and saving it as a .cam le,

shows the location of the saved le.

11 Execution

area

Contains 2 radio buttons that specify if the

selected prole should be executed in cyclic or

non-cyclic mode.

12 Loading info Text eld showing the loading state for the

selected prole.

Illustration 5.84 CAM Prole Management

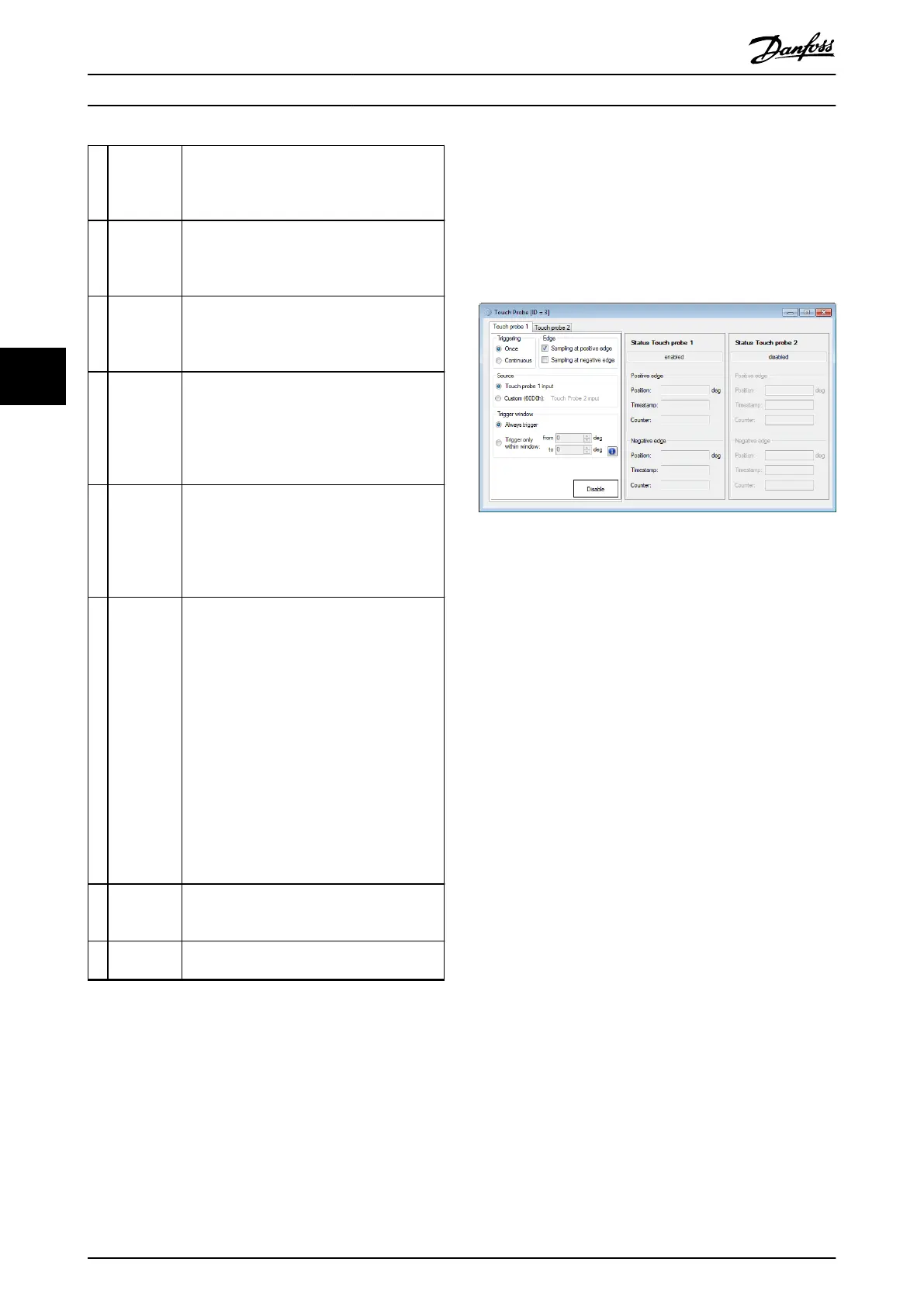

5.7.9 Touch Probe (Servo Drive only)

The Touch Probe sub-tool congures the settings of the

touch probe functionality of the servo drive. There are 2

touch probe channels available that can be used in

parallel. See chapter 2.5.2 ISD Touch Probe for more

information on the touch probe functionality.

Illustration 5.85 Touch Probe Sub-tool

5.7.10 SAB Control (SAB only)

The SAB Control sub-tool visualizes and controls the SAB

state machine and therefore can be used to enable or

disable the UDC and U

AUX

voltage on the lines, and to

reset an error. The sub-tool can only be used in cyclic

mode (direct communication) as it sends the commands to

the SAB in the form of process data objects (PDO).

The SAB Control consists of the 6 SAB states; every state is

assigned a distinct color and has a list of navigable

successor states and a list of automatic transitions that can

only be triggered by the SAB rmware itself. The SAB

states, along with their respective colors, are described in

chapter 5.5.2 Device Environment Window.

Illustration 5.86 depicts the SAB Control sub-tool containing

the

dened SAB states. The active state is highlighted with

its dened state color. The directly navigable successors of

the active state are accessible (enabled) but the others are

not accessible (disabled).

Operation with ISD Toolbox

VLT

®

Integrated Servo Drive ISD

®

510 System

158 Danfoss A/S © 01/2017 All rights reserved. MG36D102

55

Loading...

Loading...