2.4.4.6 Error Behavior in Homing Mode

For the methods where Homing limit distance (see sub-index 03: in chapter 7.13.6 Parameter 52-45 to 52-48: Additional

Homing objects (0x2040)) is used for supervising, the following error behavior applies:

If the limit is exceeded, the homing procedure is aborted. The servo drive signals a Homing error. If the servo drive is in

motion at this point of time, it ramps down with the quick stop deceleration (see chapter 7.5.9 Parameter 50-13: Quick Stop

Deceleration (0x6085)) to standstill but stays in state Operation enabled. Additionally, a warning is issued (Warning bit in

Statusword and setting of warning code).

The following situations can also lead to a warning:

•

Entering Homing mode when not in standstill.

•

Starting a homing procedure while not in standstill. A warning and a homing error are reported. If the axis reaches

standstill, the homing method is started.

•

If the homing procedure reaches the homing distance, the homing is aborted and a warning is reported.

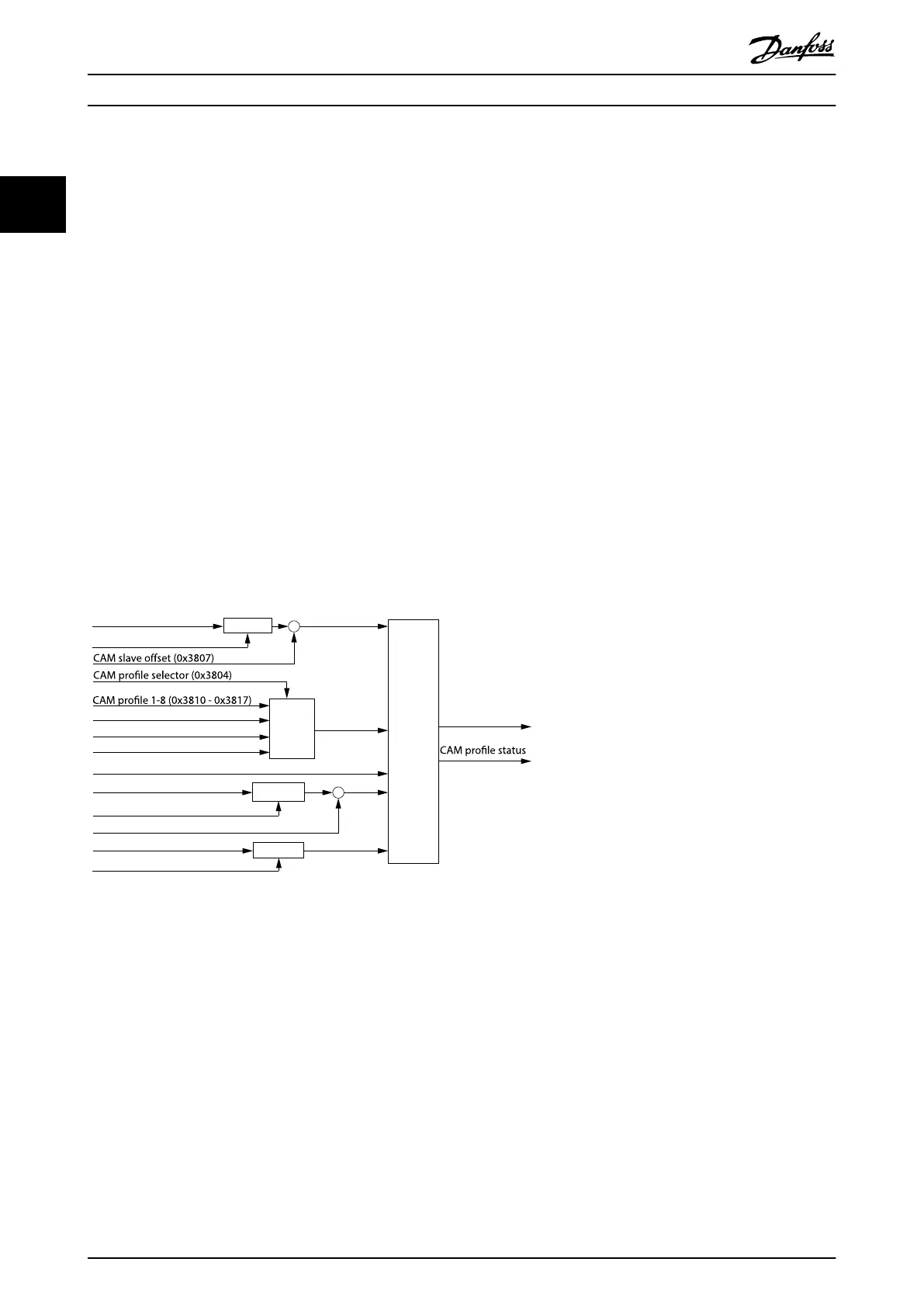

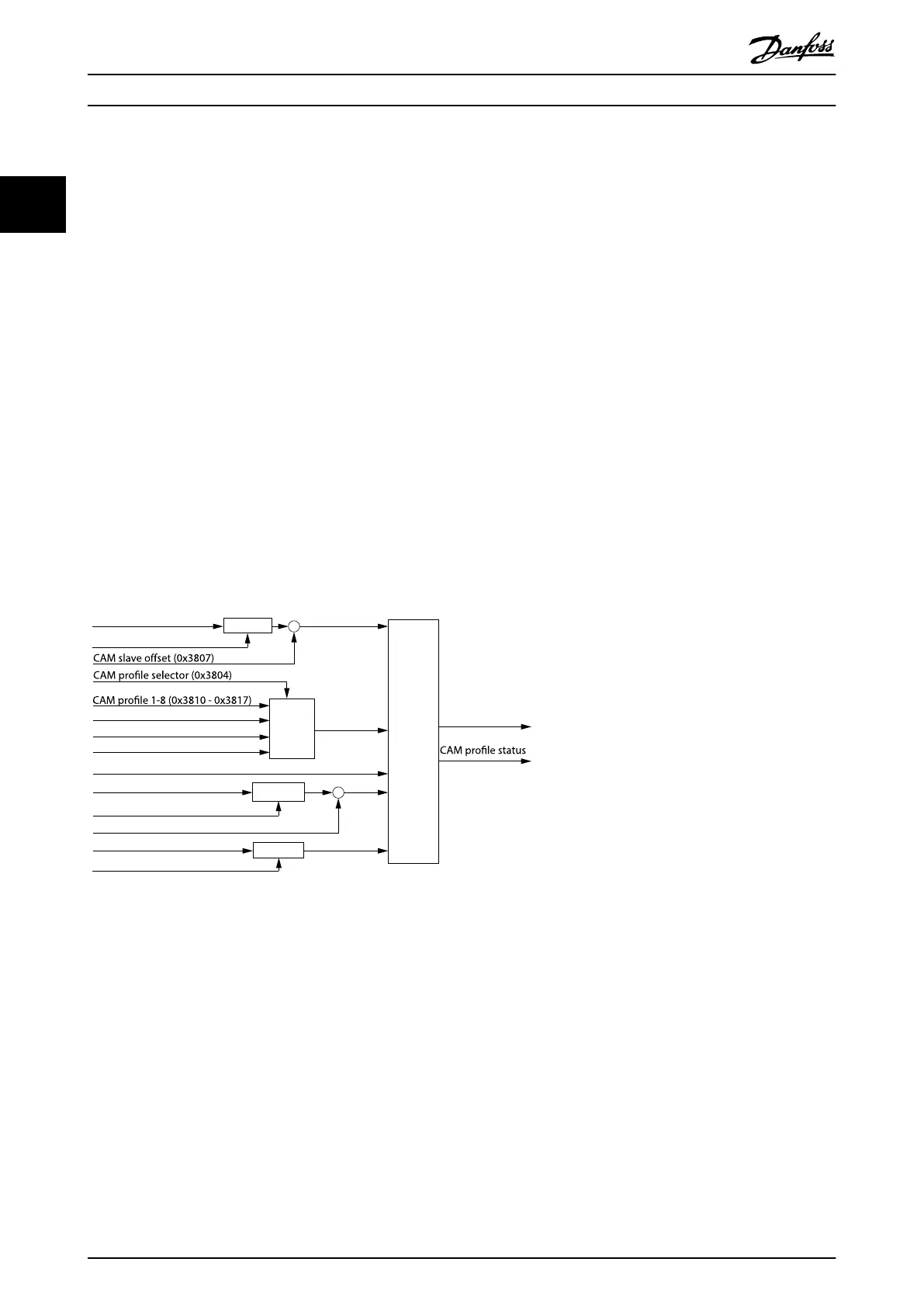

2.4.5 CAM Mode

In CAM mode, the servo drive executes a synchronized movement based on a master axis (guide value). The synchronization

takes place by means of a CAM prole that contains slave positions corresponding to master positions. CAMs are designed

with either the CAM Editor of the ISD Toolbox chapter 5.7.7 CAM Editor (Servo Drive only) or by using special structures in the

PLC library chapter 6.5.7 Drive – CAM Creation. The guide value can be provided by an external encoder, virtual axis, or the

position of another axis.

Multiplier

Logical CAM

Position (0x2020)

Selector

Multiplier

Multiplier

Trajectory

generator

Drive Position (0x2022)

CAM slave scaling (0x3809)

CAM data 1-8 (0x3820 - 0x3827)

Minimum blending distance (0x380A)

Position guide value (0x2060)

Guide value scaling factor (0x3808)

Guide value oset (0x3806)

Velocity guide value (0x2064)

Guide value scaling factor (0x3808)

+

+

Position demand

internal value

(0x60FC)

(0x3805)

130BF183.10

Illustration 2.35 Inputs for CAM Mode

When switching to CAM mode when the servo drive is not in standstill, it continues rotating with its current velocity. As

soon as a new CAM prole is activated, the new CAM prole is processed with the corresponding behavior. The servo drive

can hold a maximum of 8 CAM proles (see chapter 7.14.4 Parameters: CAM Prole 1–8 (0x3810–0x3817)). A CAM prole

consists of the CAM itself and its CAM conguration. CAM proles are automatically stored inside the servo drive.

There are 2 types of CAMs:

•

Basic CAM

A basic CAM is a list of data points that describe

the relationship between the slave position and

the master position. Each data point consists of:

- Master position

- Slave position

- Slave velocity

- Slave acceleration

•

Advanced CAM

An advanced CAM is represented by nodes,

segments, actions, and exit conditions. There are

dierent segment types that each have a special

functionality to provide intelligent application

functionality within the servo drive.

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

38 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...