The CAM is represented in an XML le, which contains the

following information:

•

Master scaling (optional)

•

Slave scaling (optional)

•

Control loop parameter (optional; both sets)

•

Following error settings (optional)

•

Basic cam or advanced cam denition

The CAM conguration consists of the following

information:

•

Cyclic/non-cyclic

•

Master absolute/relative

•

Slave absolute/ relative (only applicable for basic

CAM)

For general information about the format of an XML le,

see chapter 10.2 General XML Conventions.

When parsing a CAM prole, the servo drive checks the

format and the plausibility. The result is available in the

sub-indexes 3 and 4 of the same objects (see

chapter 7.14.4 Parameters: CAM Prole 1–8 (0x3810–0x3817)).

These sub-indexes contain detailed information about the

parsing state, error result, and more detailed information

for debugging.

The factor group (see chapter 2.3.2 Factor Group) is not

used in CAM mode. The velocity must be given as a

unitless factor between rotor angle and angle of guide

value. The acceleration must be given as velocity per

degree of guide value. A CAM prole is running based on

the guide value. This value always runs from 0 to 1. To

adjust this to the real application environment, it is

possible to specify a factor (master scaling) to reduce or

increase the value that is considered as a full cycle.

There are 2 possible CAM buer layouts available:

•

8 CAM proles

•

2 CAM proles with more data

The CAM buer layout can be selected in object 0x380F

(see chapter 7.14.1 Parameter: CAM Prole Memory Layout

(0x380F)). Carry out a power-cycle to activate the selection.

All nodes are non-signaling nodes. The axis does not

automatically signal if it passes a node. However, for

example for debugging purpose, it is possible to enable

this signaling for selected nodes.

NOTICE

The factor group (feed constant, gear ratio, and so on)

has no eect in CAM mode.

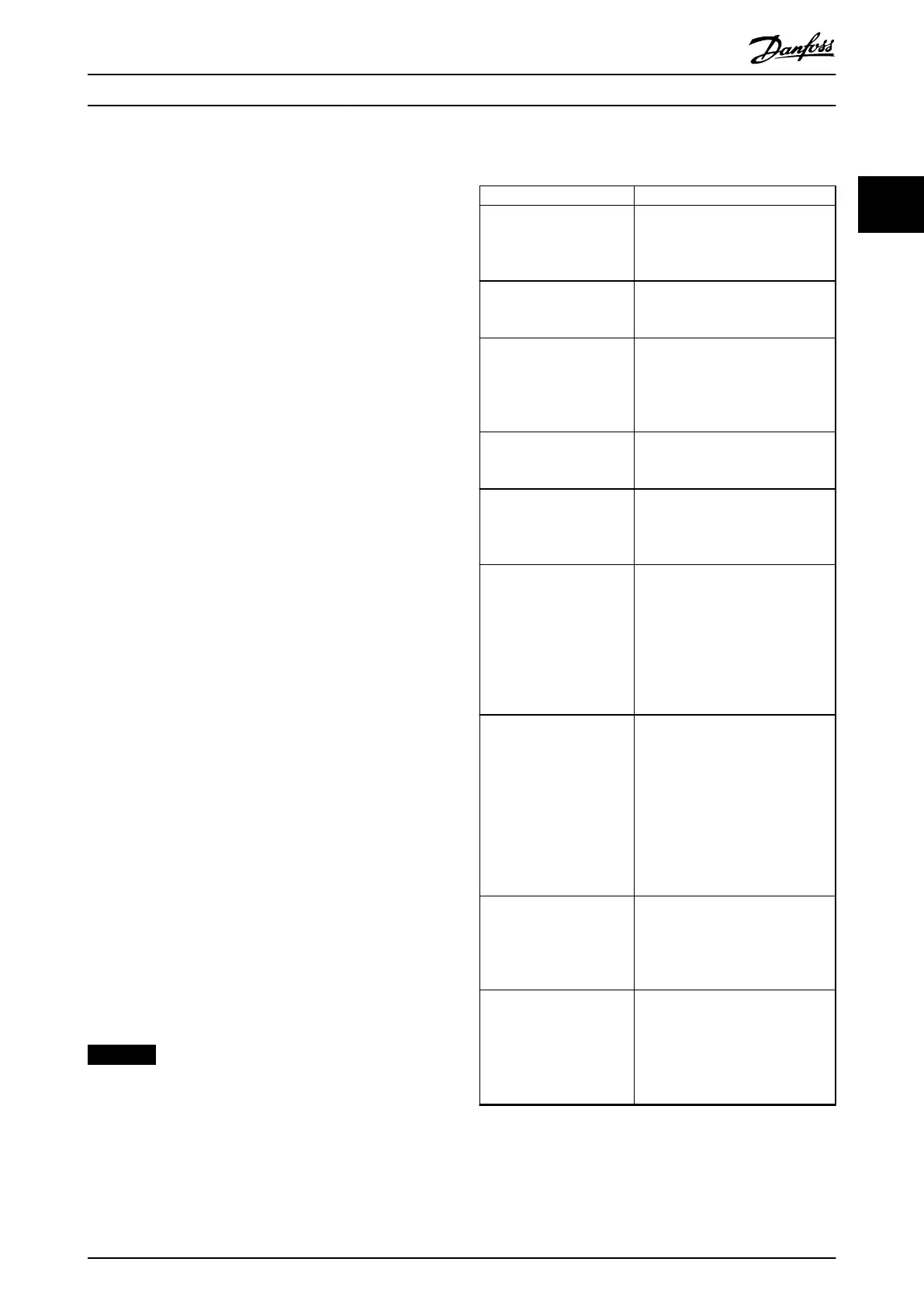

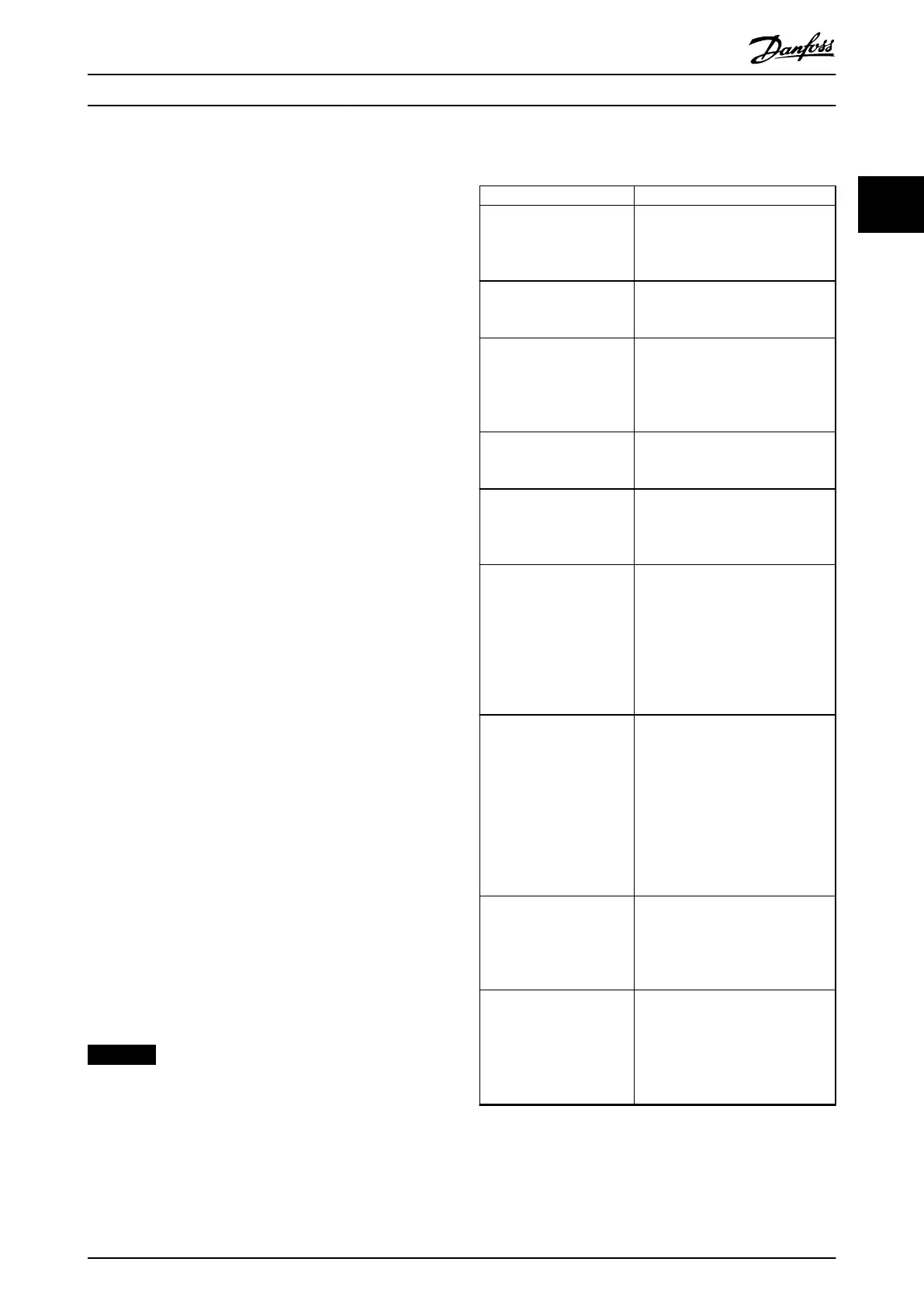

Terminology

Name Description

CAM prole Consists of 1 CAM and 1 CAM

conguration. A valid CAM prole is

automatically stored in the servo

drive (maximum 8 CAM proles).

CAM XML le (basic CAM or advanced

CAM) containing the data points or

the nodes and segments.

CAM conguration Contains the following information:

- Cyclic/non-cyclic

- Master absolute/relative

- Slave absolute/relative

Basic CAM List of data points that describe the

relationship between the slave

position and the master position.

Advanced CAM Describes the relationship between

the slave and the master based on

nodes, segments, actions, and exit

conditions.

CAM prole activation

request (Handshaking)

Handshaking procedure with

Controlword and Statusword to

activate a valid CAM prole. This

does not necessarily mean that the

prole starts immediately. This

depends on the CAM conguration,

time of CAM activation request, and

so on.

Change CAM immediate/

delayed

In the Controlword there are 2

options for changing the CAM:

- Immediate: Abort the currently

running CAM and immediately

change to the new CAM.

- Delayed: The currently running

CAM prole nishes rst before

the CAM is activated (see

Illustration 2.37).

CAM prole activation All setpoints of the CAM prole are

calculated and the servo drive is

able to run the CAM prole. This

mainly contains the calculations for

blending.

Full CAM A basic CAM that is dened with

the 1

st

data point at guide value 0

and last data point at guide value

1. The CAM is dened over the

whole guide value cycle. Not

applicable for advanced CAM.

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 39

2 2

Loading...

Loading...