Name Description

Partial CAM

A CAM that is dened with the 1

st

data point not at guide value 0 or

last data point not at guide value 1

(or both). The CAM is only dened

on part of the guide value cycle.

Parts of the guide value are

“undened”. Not applicable for

advanced CAM.

P5

Polynomial of 5

th

degree.

End of prole Output signaling the end of the

CAM prole. For cyclic processing of

the CAM, it is displayed every time

the end of the CAM prole is

reached. This signal is only high for

1 eldbus cycle. For basic CAMs, the

end of prole is signaled at the last

data point. For advanced CAMs, the

end of prole is signaled at each

end node.

InSync Output InSync is high as long as the

slave follows the commanded CAM

prole.

Blending Blending occurs whenever the servo

drive automatically calculates a P5

when switching between CAMs, or

it is used to ll up the undened

parts in cyclic processing of CAMs.

Table 2.5 Terminology

2.4.5.1 Activating a CAM prole

Perform the following steps to activate a CAM prole:

1. Write the CAM data to 1 of the objects 0x3820–

0x3827: CAM data 1–8 (see

chapter 7.14.5 Parameters: CAM Data 1–8 (0x3820–

3827)).

2. Write the CAM conguration and activate the

CAM parsing to the corresponding object

0x3810–0x3817: CAM prole, sub-index 01 (see

chapter 7.14.4 Parameters: CAM Prole 1–8

(0x3810–0x3817)).

3. Check the CAM parsing state in objects 0x3810–

0x3817: CAM prole, sub-index 02 and 03 (see

chapter 7.14.4 Parameters: CAM Prole 1–8

(0x3810–0x3817)).

4. Write the number of the CAM and the delay code

that should be used into object 0x3804: CAM

prole selector (see chapter 7.14.7 Parameter: CAM

Prole Selector (0x3804).

5. Switch to CAM mode (this can also be done

earlier).

6. Perform handshaking to send the CAM activation

request.

To transfer a CAM prole, use function block MC_CamTable-

Select_ISD51x (see

chapter 6.5.6.1 MC_CamTableSelect_ISD51x).

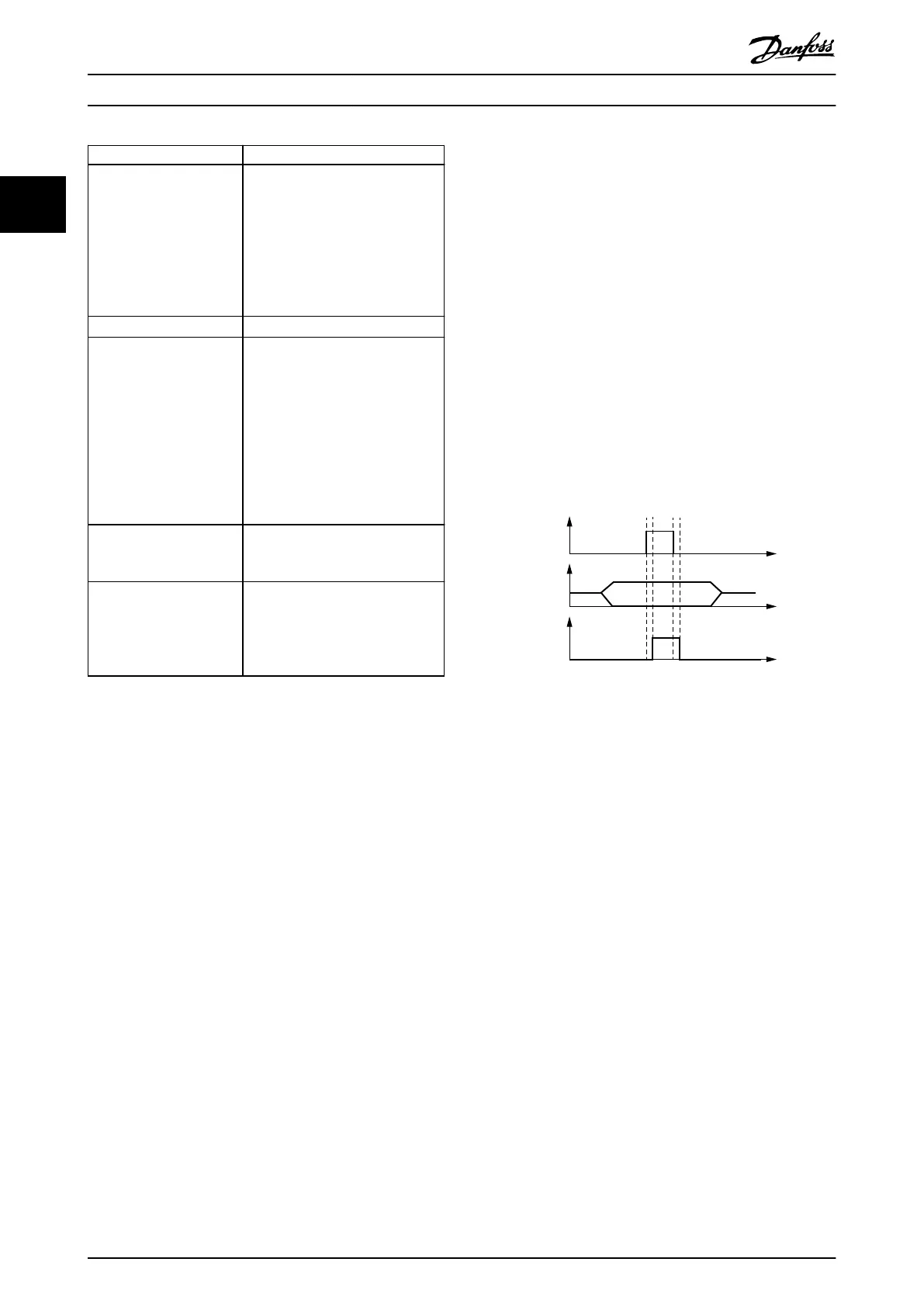

CAM prole activation request (Handshaking)

The activation of a CAM prole is controlled by the timing

of the New CAM bit in the Controlword, and the CAM ack

bit in the Statusword. After a CAM prole is transferred and

successfully parsed, the control device signals that the

CAM prole will be activated (CAM prole activation

request) by a rising edge of the New CAM bit in the

Controlword. The axis internally calculates all necessary

parameters and afterwards sets the CAM ack bit in the

Statusword to 1. With the CAM ack bit set to 0, the axis

signals its ability to accept new CAM proles. An example

is shown in Illustration 2.36. After activation of the CAM

prole, the CAM is not necessarily executed immediately.

This depends on the CAM conguration and the change

immediate bit in the Controlword.

New CAM

(Bit 4)

CAM

prole

selector

CAM ack

(Bit 12)

Illustration 2.36 Handshaking Procedure for CAM Prole

Activation

The CAM prole can also be activated using function block

MC_CamIn_ISD51x (see chapter 6.5.6.2 MC_CamIn_ISD51x).

The axis supports a set of 2 CAM proles numbers: a CAM

prole that is currently being processed, and a buered

prole.

If a CAM prole is still in progress and a new CAM prole

is validated by the new CAM (bit 4) in the Controlword, 2

methods of handling are supported:

•

The new CAM prole is activated immediately

(Change CAM immediately bit of the Controlword

is set to 1).

•

The currently active CAM prole is nished rst

and afterwards the new CAM prole is started

(Change CAM immediately bit of the Controlword

is set to 0).

When a new CAM prole is activated, all specic

parameters are activated at the start of the new prole

(this is the beginning of the blending). This can lead to

jumps in position and velocity, for example when using

dierent master scaling values.

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

40 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...