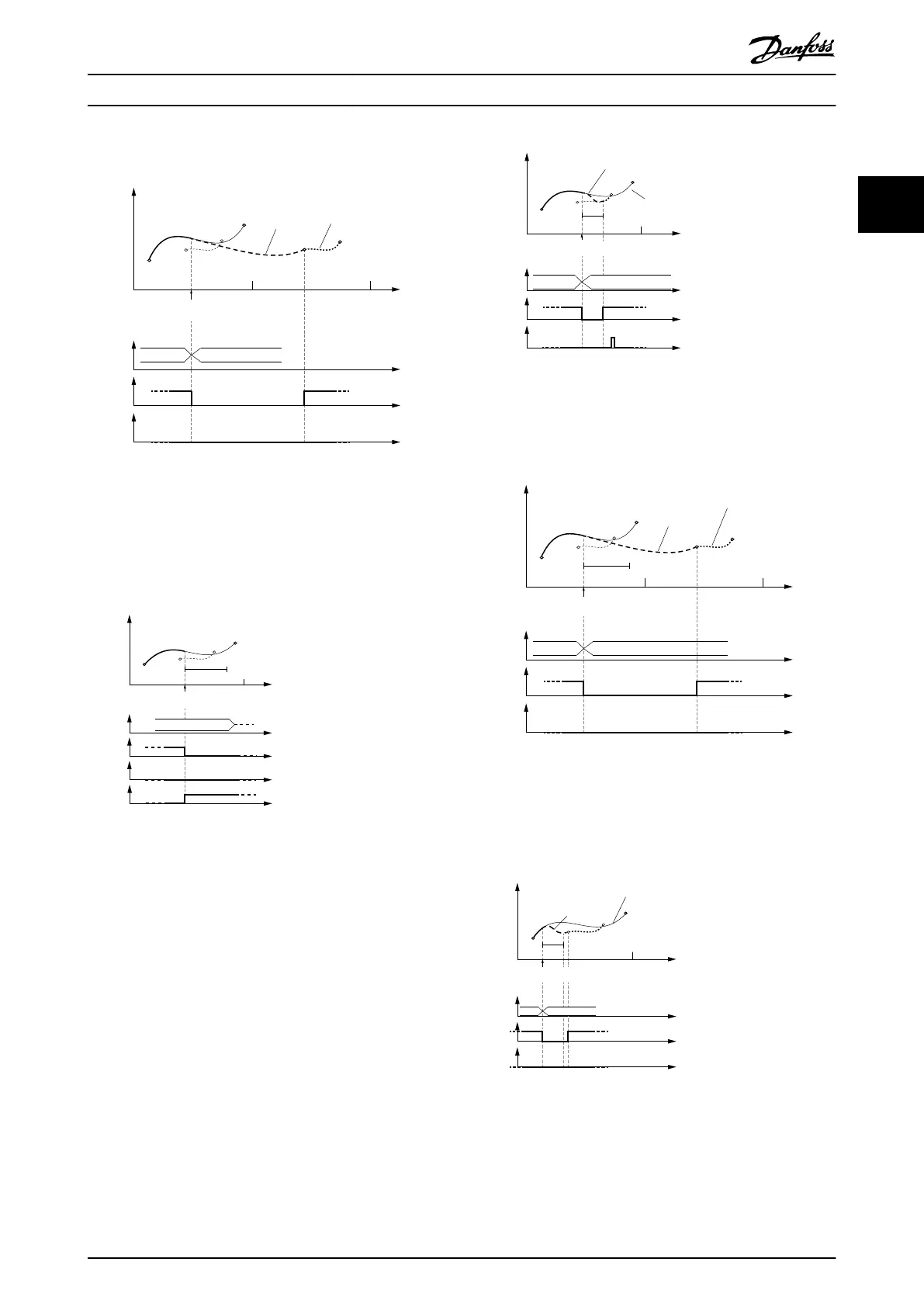

Rotor angle of axis

0 1 2

Master absolute

Slave absolute

Blending

Change CAM Imm=1

Use blend dist=0

InSync

End of

Prole

Active

CAM

Guide value

cycle

CAM 2 CAM 3

Illustration 2.53 Change CAM immediately = 1.

No blending distance used. The blending is then done

automatically to the beginning of the new CAM. It does not

necessarily mean that this is in the next cycle (for example,

see Illustration 2.57).

130BF267.10

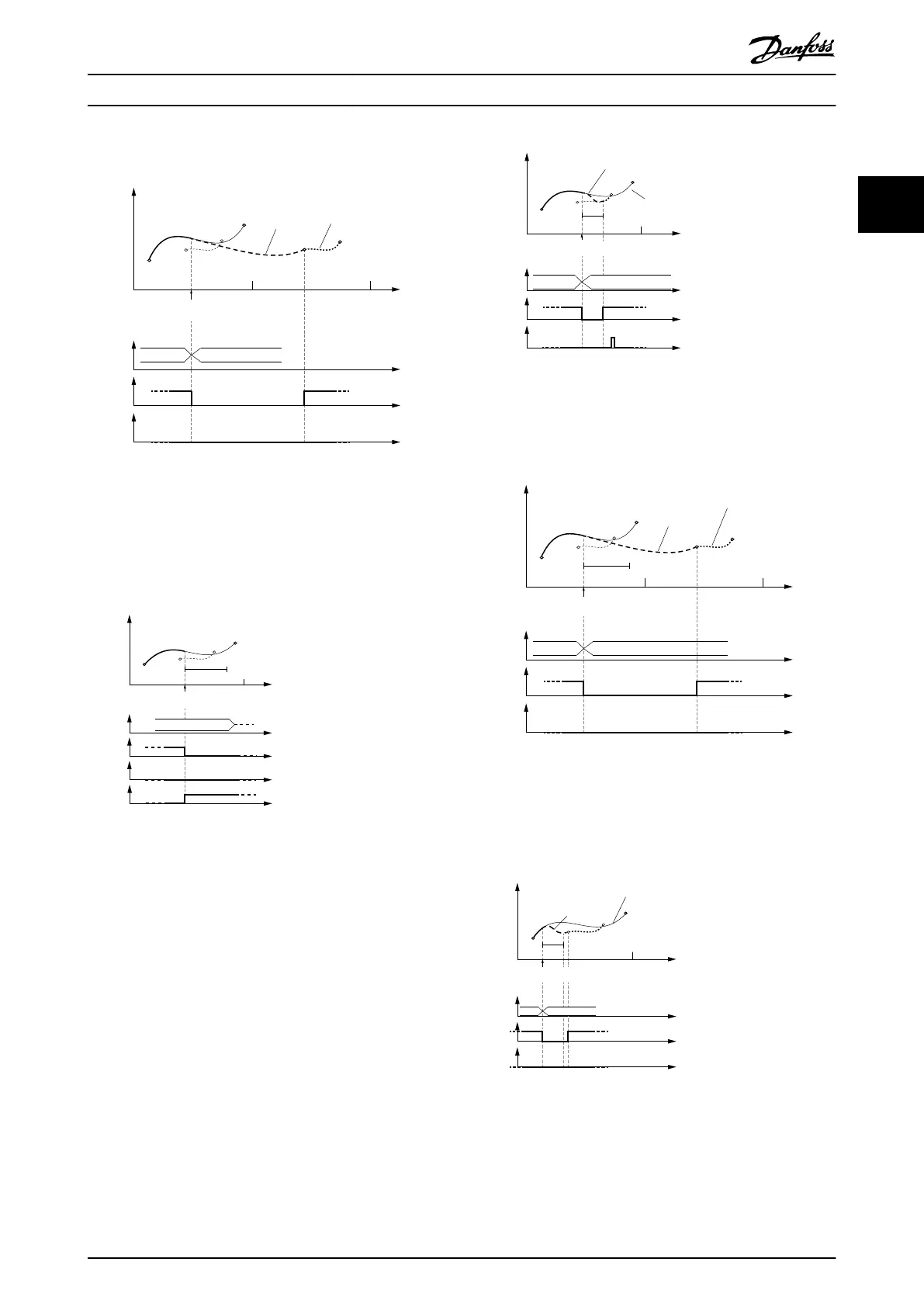

Rotor angle of axis

10

Master absolute

Slave absolute

Non-Cyclic

blend

dist

CAM

Error

Active

CAM

InSync

End of

prole

Change CAM imm=1

Use blend dist=1

Guide value

cycle

CAM 2

Illustration 2.54 The end of the blend distance is not on the

new CAM in the same guide value cycle.

This situation leads to a reject of the transition. An error is

issued because the 1

st

CAM was aborted with Change CAM

imm = 1.

Rotor angle of axis

130BF269.10

Master absolute

Slave absolute

0 1

Active

CAM

InSync

End of

prole

Blending

blend

dist

Change CAM imm=1

Use blend dist=1

Guide value

cycle

CAM 2 CAM 3

Illustration 2.55 Change CAM immediately = 1.

Use blending distance; Blending is possible to the new CAM

prole in the same cycle.

Rotor angle of axis

0 1 2

Master absolute

Slave absolute

Cyclic

Blending

blend

dist

Active

CAM

InSync

End of

prole

Change CAM imm=1

Use blend dist=1

Guide value

cycle

CAM 2 CAM 3

Illustration 2.56 Change CAM immediately = 1.

Use blending distance; Blending distance ends after the new

CAM prole ends; Blending is then extended to the starting

point of the next cycle.

Rotor angle of axis

130BF270.10

Master absolute

Slave absolute

0 1

Blending

Active

CAM

InSync

End of

prole

blend

dist

Change CAM imm=1

Use blend dist=1

Guide value

cycle

CAM 2 CAM 3

Illustration 2.57 Use blending distance; Blending distance is

not long enough to reach the next CAM.

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 47

2 2

Loading...

Loading...