Absolute master position, relative slave position

Change CAM immediately = 0:

The currently running CAM is processed until the end. The

1

st

slave position of the new CAM is adjusted so that it

matches the slave position of the end point of the old

CAM prole.

Change CAM immediately = 1:

The currently running CAM is aborted immediately. The

slave position of the new CAM at the current guide value

is adjusted so that it matches the current slave position. If

the new CAM has not dened at this current guide value,

the slave value of the 1

st

point of the new CAM is adjusted

so that it matches the current slave position.

The behavior when switching to non-cyclic CAM

proles is

the same as detailed in section Absolute master position,

absolute slave position in chapter 2.4.5.4 Basic CAM. Options

slave absolute and slave relative have no inuence in these

cases and are therefore not mentioned again in this

section.

0 1 2

Active

CAM

InSync

End of

CAM 2 CAM 3

Slave

relative

Blending Master absolute

Slave relative

130BF272.10

Guide value

cycle

Rotor angle of axis

Change CAM imm=0

Use blend dist=0

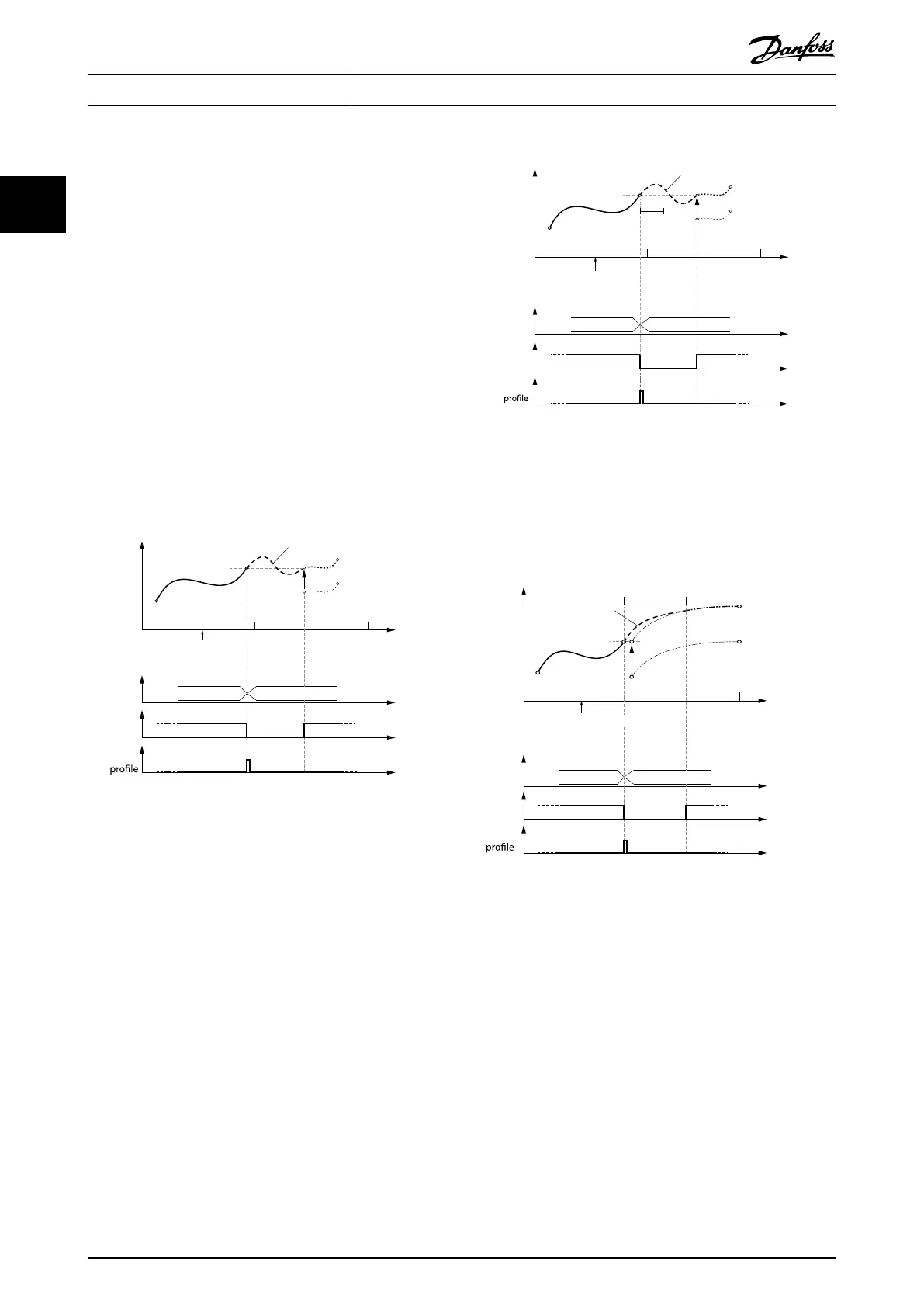

Illustration 2.58 Transition with absolute master and relative

slave positioning;

No blending distance used.

0 1 2

Active

CAM

InSync

End of

CAM 2 CAM 3

Slave

relative

Blending

Master absolute

Slave relative

Cyclic

Guide value

cycle

Rotor angle of axis

blend

dist

Change CAM imm=0

Use blend dist=1

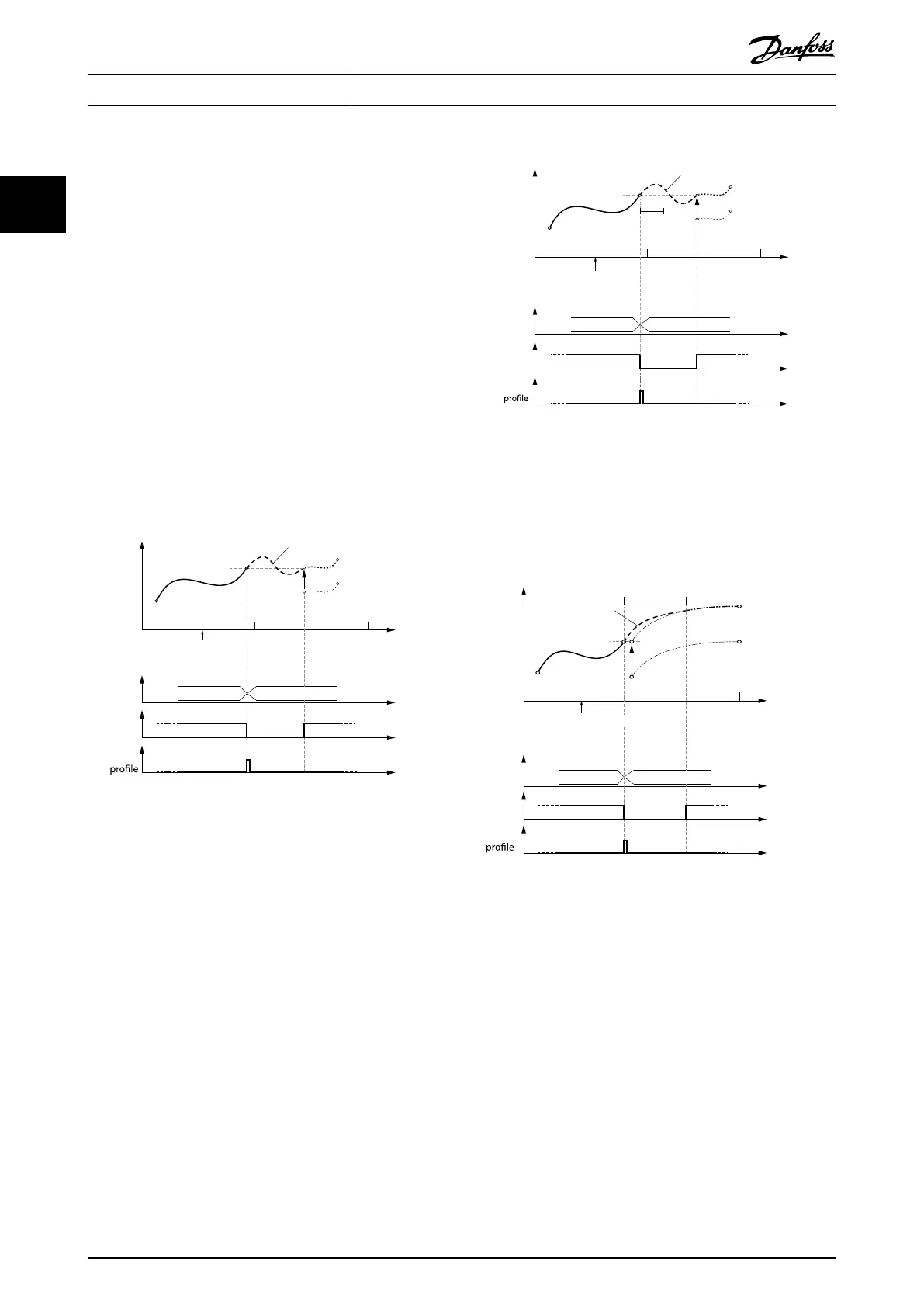

Illustration 2.59 Change CAM immediately = 0.

Use blending distance; Blending distance is not long enough

to reach the next CAM.

Guide value

cycle

Rotor angle of axis

CAM 2 CAM 1

Slave

relative

Master absolute

Slave relative

Cyclic

Blending

blend

dist

Active

CAM

InSync

End of

Change CAM imm=0

Use blend dist=1

Illustration 2.60 Change CAM immediately = 0.

Use blending distance; Blending distance is long enough to

cover the gap to the next CAM.

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

48 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...