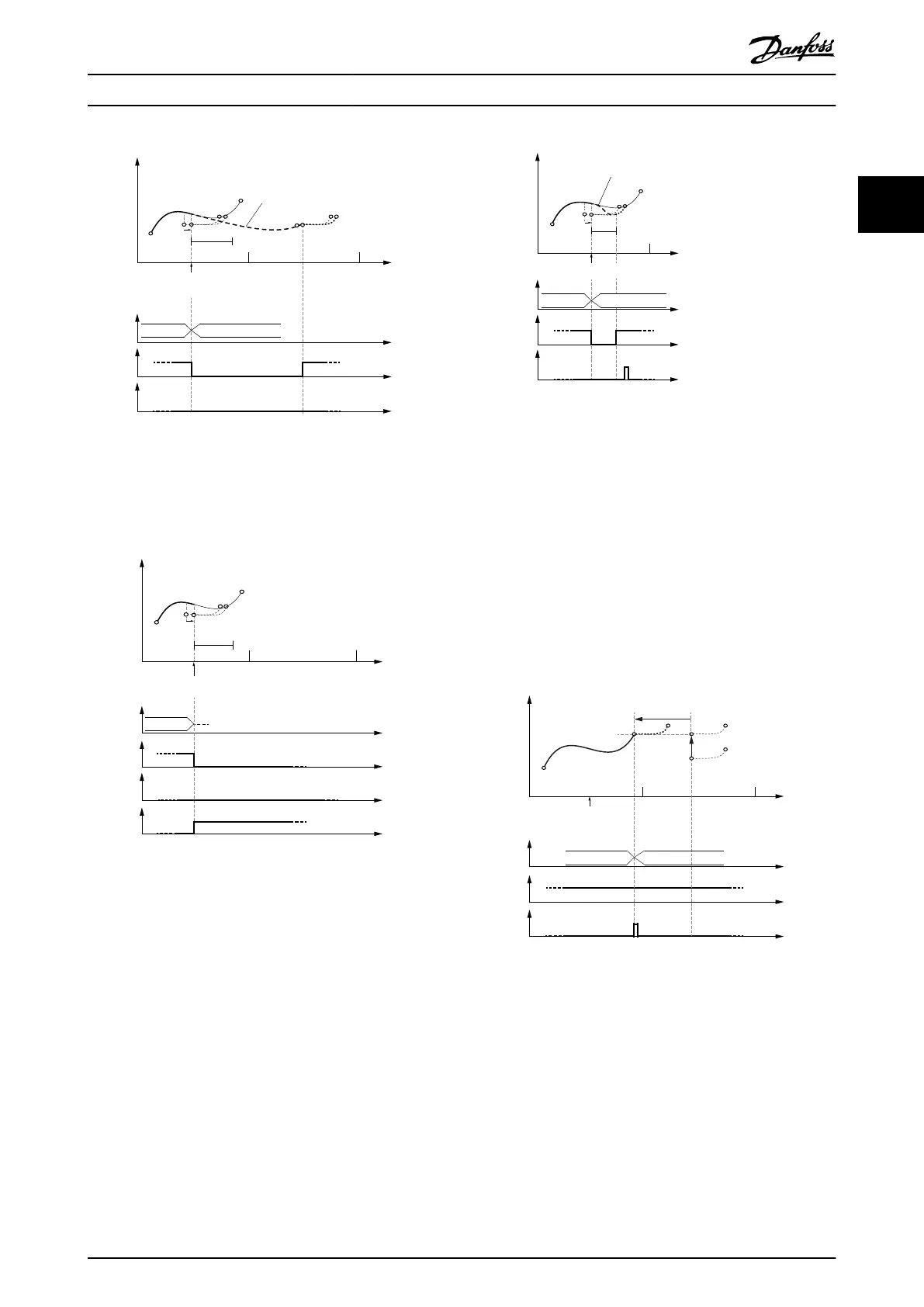

Guide value

cycle

Rotor angle of axis

0

1

2

Master relative

Slave absolute

Cyclic

Active

CAM

InSync

End of

prole

Change CAM imm=1

Use blend dist=1

Master

relative

blend

dist

Blending

CAM 2 CAM 3

Illustration 2.70 Change CAM immediately = 1.

Use blending distance; Blending distance ends after the end

point of the new CAM.

Guide value

cycle

Rotor angle of axis

0

1 2

Master relative

Slave absolute

Non- cyclic

blend

dist

Master

relative

Change CAM imm=1

Use blend dist=1

Active

CAM

InSync

End of

prole

CAM

Error

CAM 2

Illustration 2.71 The end of the blend distance is not on the

new CAM.

The transition is rejected and the servo drive acts as if the

command was never issued.

130BF284.10

Master relative

Slave absolute

blend distMaster

relative

Guide value

cycle

Rotor angle of axis

0

1

Change CAM imm=1

Use blend dist=1

Active

CAM

InSync

End of

prole

Blending

CAM 2 CAM 3

Illustration 2.72 Change CAM immediately = 1.

Use blending distance; Blending distance is shorter than the

new CAM prole.

Relative master position, relative slave position

The processing starts as soon as the CAM prole is

activated. The 1

st

point of the CAM prole is moved to the

current position and guide value. The behavior when

switching to non-cyclic CAM proles is the same as shown

in section Relative master position, absolute slave position in

chapter 2.4.5.4 Basic CAM. Option slave absolute or slave

relative has no inuence in these cases and is therefore not

mentioned again in this chapter.

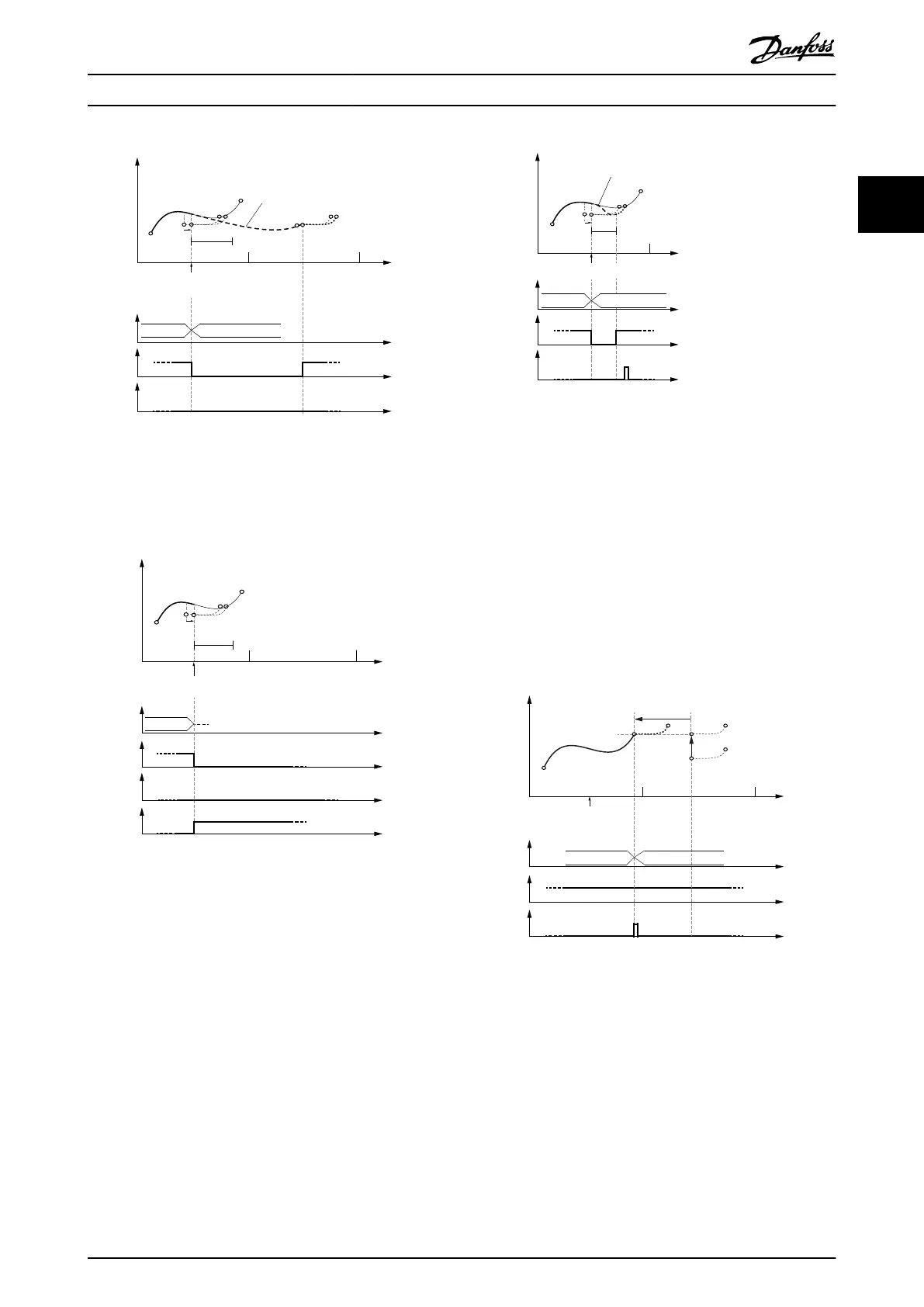

Guide value

cycle

Rotor angle of axis

0

1

2

CAM 2 CAM 3

Active

CAM

InSync

End of

prole

Change CAM imm=0

Use blend dist=0

Master relative

Slave relative

Master relative

Jump in

velocity possible!

Slave

relative

Illustration 2.73 CAM prole with relative master and relative

slave positioning.

A jump in velocity may occur if the CAMs do not match.

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 51

2 2

Loading...

Loading...