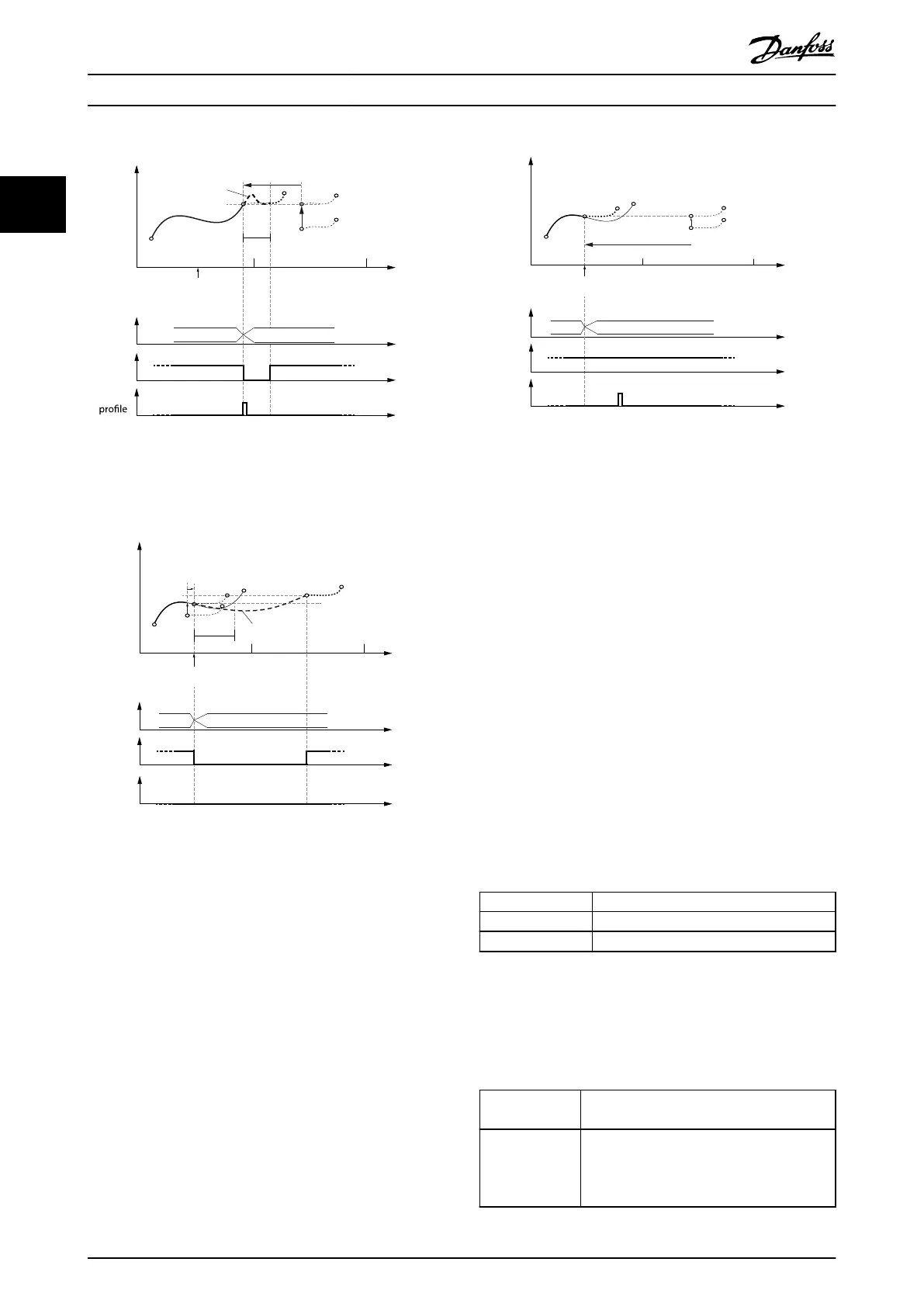

Guide value

cycle

Rotor angle of axis

0

1

2

CAM 2 CAM 3

Active

CAM

InSync

End of

Change CAM imm=0

Use blend dist=1

Master relative

Slave relative

Master relative

Slave

relative

Blending

blend dist

Illustration 2.74 Change CAM immediately = 0.

Use blending distance.

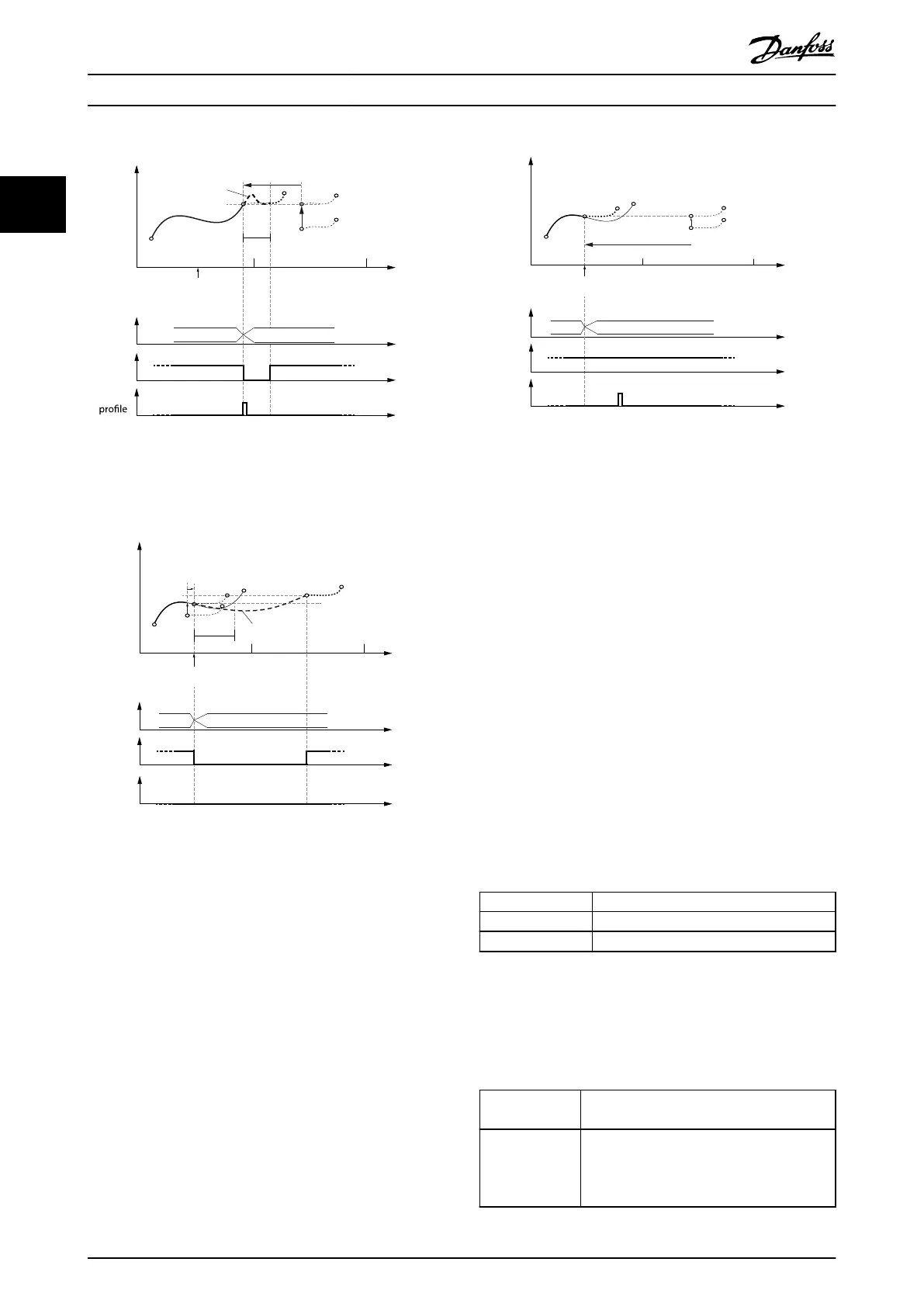

Guide value

cycle

Rotor angle of axis

0

1

2

Active

CAM

InSync

End of

prole

CAM 2 CAM 3

Change CAM imm=1

Use blend dist=1

Master relative

Slave relative

Cyclic

Slave

relative

Master

relative

Blending

blend

dist

Illustration 2.75 Change CAM immediately = 1.

Use blending distance; Distance is longer than the new CAM.

130BF288.10

Guide value

cycle

Rotor angle of axis

0

1

2

CAM 2 CAM 3

Active

CAM

InSync

End of

prole

Change CAM imm=1

Use blend dist=0

Master relative

Jump in

velocity possible!

Slave

relative

Master relative

Slave relative

Illustration 2.76 Change CAM immediately = 1.

Do not use blending distance. Jumps in velocity may occur.

2.4.5.5 Advanced CAM

The advanced CAM is represented by nodes and segments.

The available node types are described in Table 2.13. The

available segment types are described in Table 2.14.

The CAM conguration options Slave absolute and Slave

relative are not available for advanced CAM. In advanced

CAM, the behavior of an absolute or relative movement is

built in to the dierent segment types.

A dierentiation between full and partial CAM is not

applicable for advanced CAM. An advanced CAM can

contain paths that form a circle, and alternative paths (see

Illustration 2.78), which end at nodes without further

following segment.

An advanced CAM prole can consist of several nodes,

segments, actions, and exit conditions. The size of a CAM

prole highly depends on the number of elements and, for

example, on the segment types (some require more and

others require fewer parameters).

Name Description

GuideNode Connects GuideSegments

EventNode Connects EventSegments

Table 2.13 Available Node Types

All nodes are non-signaling nodes. The axis does not

automatically signal if it passes a node. However, for

example for debugging purposes, it is possible to enable

this signaling for selected nodes.

GuidePoly GuideSegment

Polynomial of 5

th

order based on guide value.

MoveDistance-

Segment

GuideSegment

Uses run-time calculated polynomial of 5

th

order; the angle is sent over eldbus at run-

time.

Servo Drive Operation

VLT

®

Integrated Servo Drive ISD

®

510 System

52 Danfoss A/S © 01/2017 All rights reserved. MG36D102

22

Loading...

Loading...