4. Troubleshooting

45530

5/14

45530

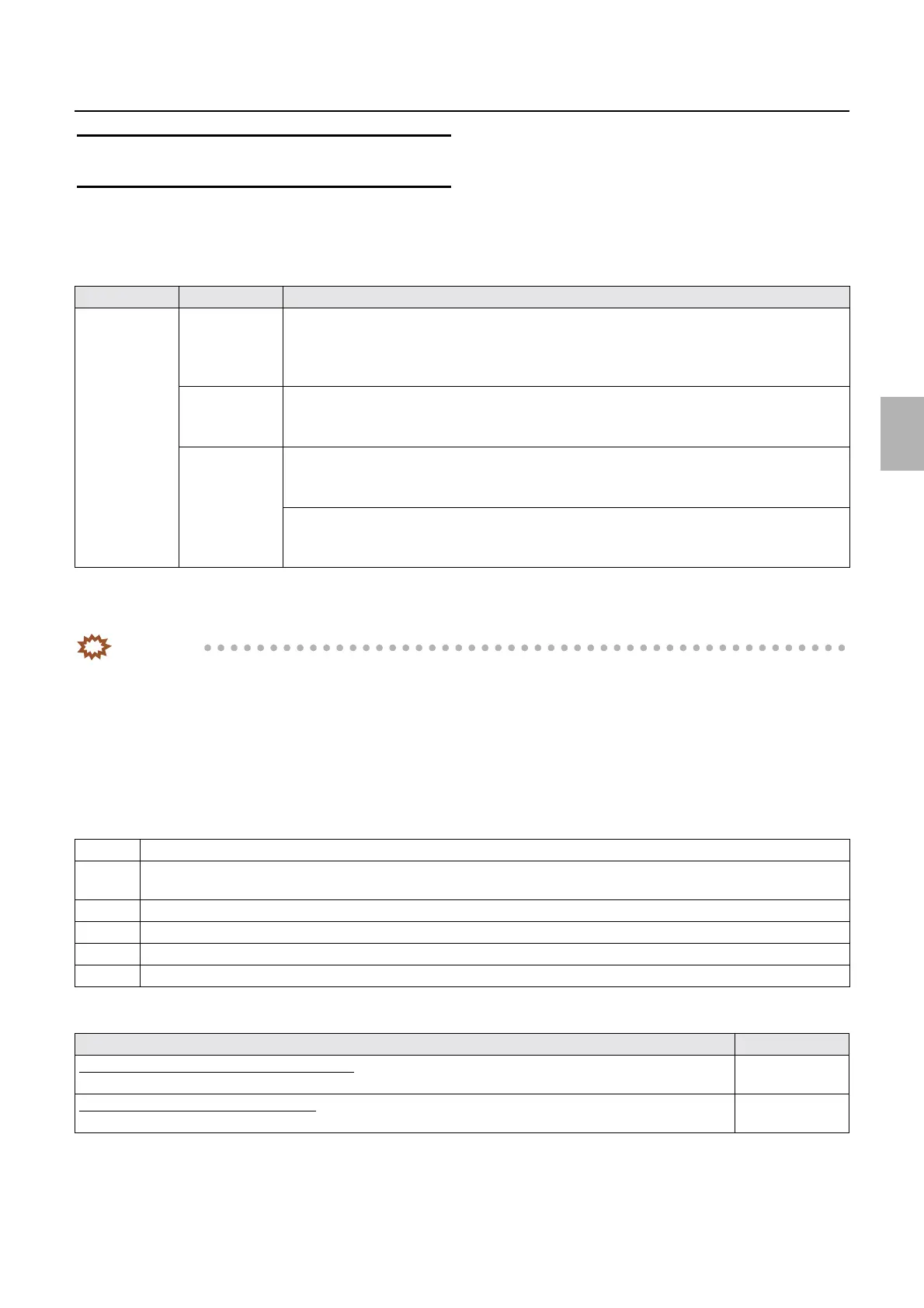

Error: Processor 2

No. 05535

Paper has jammed in the processor section.

Error message release

YES

Condition

*1. If prints are output to the print conveyor unit

*2. If prints are output to the print receiving tray (large)

*3. If prints are fed to the colorimeter unit

IMPORTANT

• The error above may occur when the ARCNET communication status is not normal.

If the error occurs, check the following items.

• Check the ARCNET communication status on the Version Check display.

☞35500

• Check the ARCNET communication path.

☞50520

• For details about the diagnosis of ARCNET communication error, see

☞35940.

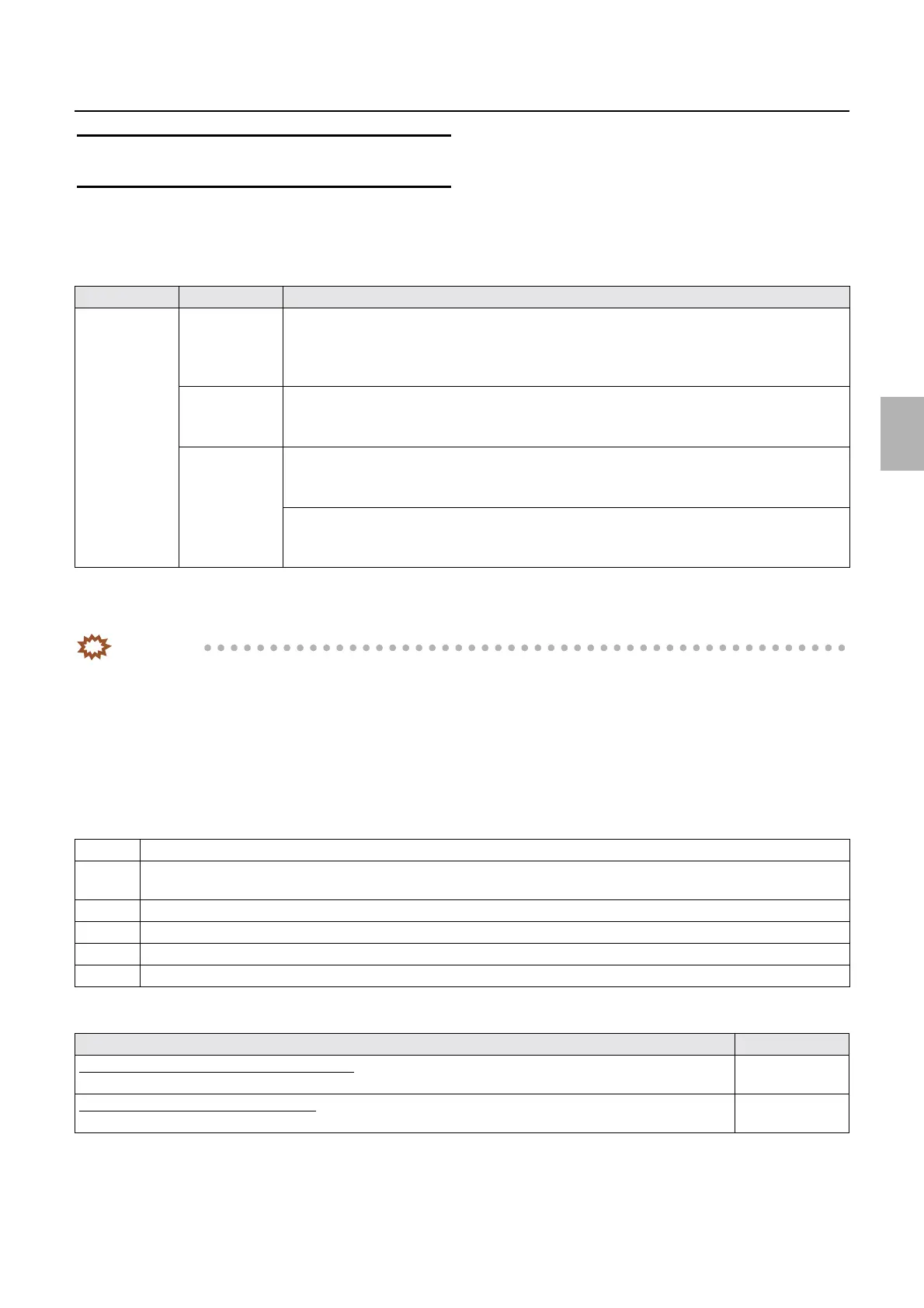

Check Point

Diagnosis

Suffix number Status Condition

00000 Normal

process

*1

• After the printer feeds out the paper to the processor, Print Sensor (Left), Print Sensor

(Center) or Print Sensor (Right) in the dryer section do not turn DARK within a specified

time.

• For details, see ☞56100 Paper advance operation of the processor (normal prints).

Normal

process

*2

• After the printer feeds out the paper to the processor, Dryer Lane Select Sensor in the dryer

section do not turn DARK within a specified time.

• For details, see

☞56100 Paper advance operation of the processor (normal prints).

Automatic color

measurement

*3

• When the colorimeter unit paper sensor 1 does not turn DARK within a specified time in

performing the automated color measurement of setup print

• For details, see

☞56110 Paper advance operation of the processor (setup prints).

• After a setup print is fed to the processor, the Dryer Lane Select Sensor does not detect

DARK within a specified time.

• For details, see

☞56610Automatic color measurement operation for setup prints.

1 Confirm that the upper guides and the squeegee unit are securely attached.

2 Confirm that the gears and the rollers rotate smoothly after removing the paper processing rack from the processing solution

tank.

3 Confirm that the lower turn belt of the paper processing rack is damaged.

4 Confirm that paper remains on each sensor.☞35220

5 Confirm that the paper guide of the dryer rack is correctly attached.

6 Confirm that the print sensor is soiled.

Adjustment failure Manual No.

If paper jam occurs during automatic colorimetry

Check the setting of Dryer Section Setting (Auto Setup).

☞33505

If paper jam occurs during normal process

Perform paper sensor adjustment.

☞33001

Distributed by: minilablaser.com

Loading...

Loading...