7-11

- SV Series User’s Manual -

PARAMETER SETTING AND OPERATION OF PULSE/ANALOG INPUT

7-4 Speed Control

In the speed control mode, a specified speed is applied on the servo motor by inputting an analog voltage signal or

speed command into the servo amplifier.

Rotation direction is switched through the "Forward start (ST1)"/"Reversal start (ST2)" input.

In speed control, the speed command can be adjusted with the speed command soft start used for smoothing speed

command or with the gain settings/filter settings/offset adjustment of analog speed input.

Additionally, the following functions are also available: the torque limit function which keeps the torque within a certain

range; the "Velocity match (VCMP)" signal which detects whether the specified speed is reached; as well as the zero

clamp function which executes servo lock when the motor drops below a certain speed.

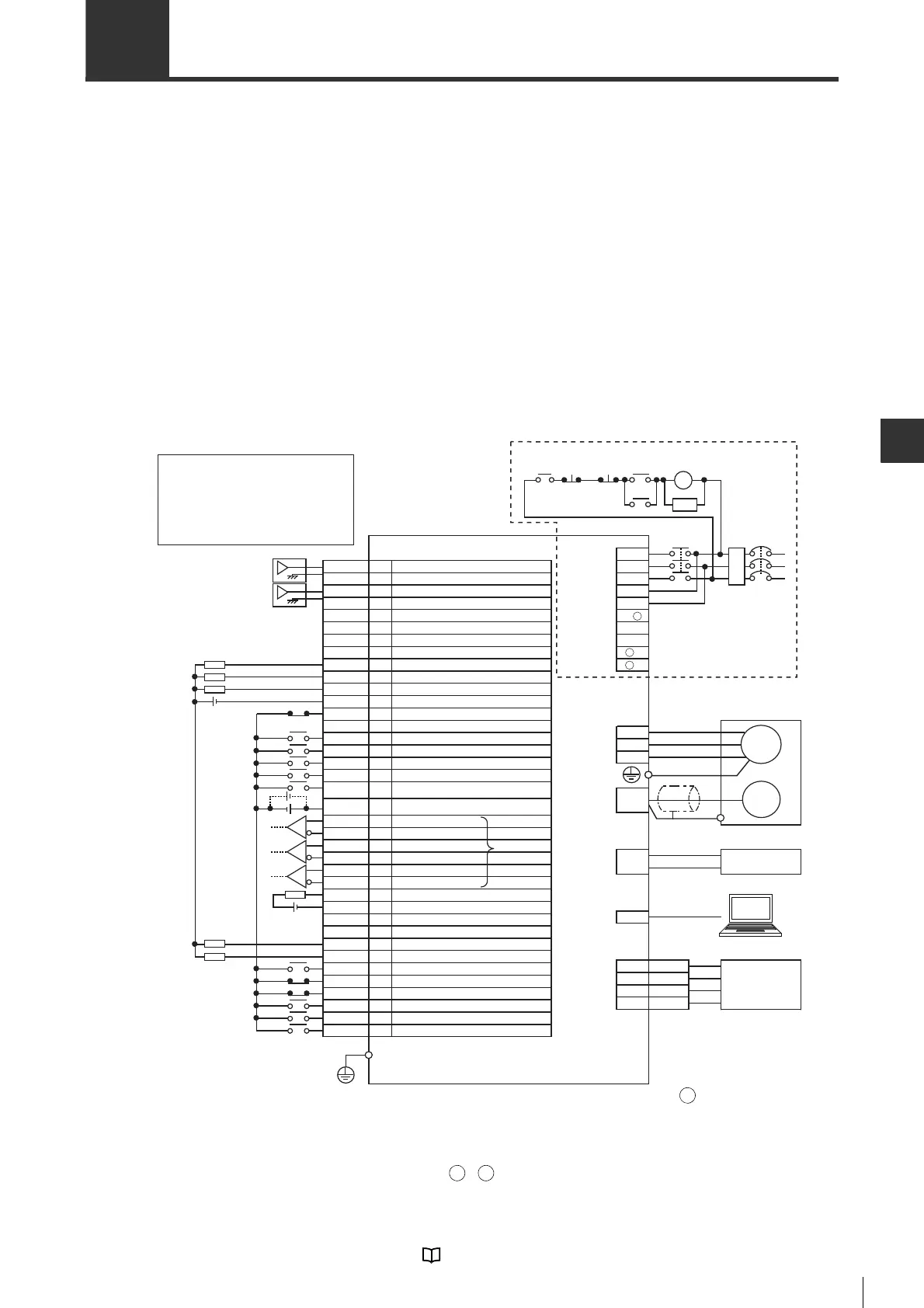

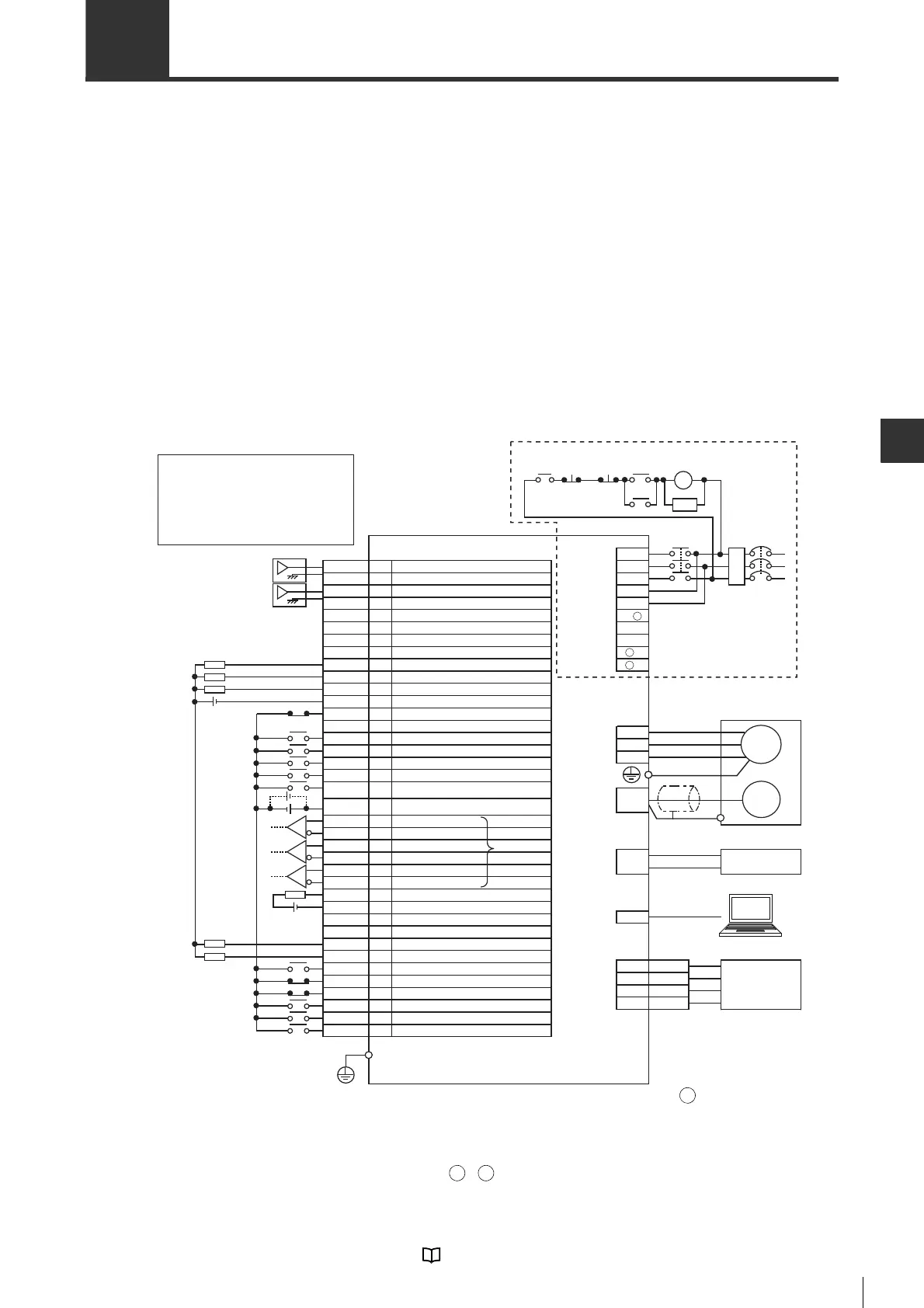

■ Pin assignment and wiring

For speed control mode, the following wiring diagram can be used.

Wiring is different when using power supplies of AC 100V,

single-phase AC 200V and DC200V. Please see

"Wiring

the Main Circuit/Control Circuit and Motor Power Supply

Connector", page 4-7

.

*1 When an external regenerative resistor is used, the same is connected between B1/ -B2. SV-075P2/100P2/

150P2/200P2/300P2/500P2 has a built-in regenerative resistor. B2 and B3 are short-circuited. The wire

between B2 and B3 should be disconnected before the external regenerative resistor is connected.

*2 These are short-circuited when delivered. No polarity needs to be considered when connecting a DC reactor.

*3 The AC100V type servo amplifier has no L3/ 1/ 2 terminals..

*4

The differential line driver is equivalent to AM26C31.

*5 SG (signal groud) is short-circuited internally.

*6 During the speed control process, depending on parameter settings, this goes to the torque feedforward mode.

For wiring and I/O terminal specification, see "4-5 Wiring I/O Signals", Page 4-24.

NFB No fuse breakeer

MC Magnetic contactor

SA Surge absorber (surge killer)

M Motor

ENC Encoder

RA Alarm output relay

FIL Noise filter

COM1

VCMP

TLM

SG

ALARM

COM0

A+

ˉ

SVON

ˉ

ST2

ˉ

ˉ

SPD2

FSTOP

V-REF

SG

T-REF

A

-

Z+

B

-

ˉ

SEN

ZSP

ST1

RDY

B+

NTL

ZOC

SG

Z

-

RESET

PTL

LSN

LSP

ˉ

ˉ

SPD1

I/O connector

Analog torque limit *6

Signal ground *5

Analog speed command

Unused

Unused

Unused

Unused

Signal ground *5

Operation ready

Encoder pulse Z phase +

CW start

Absolute position data request

Servo ON

Encoder pulse B phase -

Encoder pulse Z phase -

Limit switch negative

Alarm reset

Zero speed detection

CCW start

Limit switch positive

Output common

Speed matching

Encoder pulse Z phase open collector

Signal ground *5

Encoder pulse A phase +

Negative torque limit selection

Speed selection 1

Encoder pulse A phase -

Encoder pulse B phase +

Alarm

Speed selection 2

Unused

Forced stop

Limiting torque

Positive torque limit selection

Unused

Unused

Input common point

NFB

Servo motor

*1

Emergency

stop

MC

SA

*2

MC

Analog

monitor

connector

Protective ground terminal

AC 200V type servo amplifier

T

FIL

R

S

Main circuit/

controlcircuit

power supply

connector

*3

Lithium battery with battery housing

+

-

Battery

connector

TMON

SG

2

4

PC

USB

connector

Measuring instrument

VTG

SG

1

3

V

W

Encoder

connector

Motor power

supply

connector

U

M

ENC

MC

Main

circuit

ON

3

4

5

6

7

8

10

11

14

15

16

17

18

19

20

21

22

23

*4

Main

circuit

OFF

RA

B2

B3

L2

L1C

L3

L2C

L1

B1/

+

-

1

-

2

RA

24V

24V

24V

26

27

28

29

30

31

32

33

34

35

38

39

41

42

43

44

45

46

24

25

Loading...

Loading...