3-5

3-1 Installation

INSTALLATION AND MAINTENANCE

- SV Series User’s Manual -

● Mounting

The anti-rust agent on the shaft coated end of servo motor must be cleaned before combining with machine.

For combination with machine, the shaft center of servo motor must be aligned with the shaft center of machine,

before connecting them together with a coupling, otherwise, the shaft or bearings will be damaged.

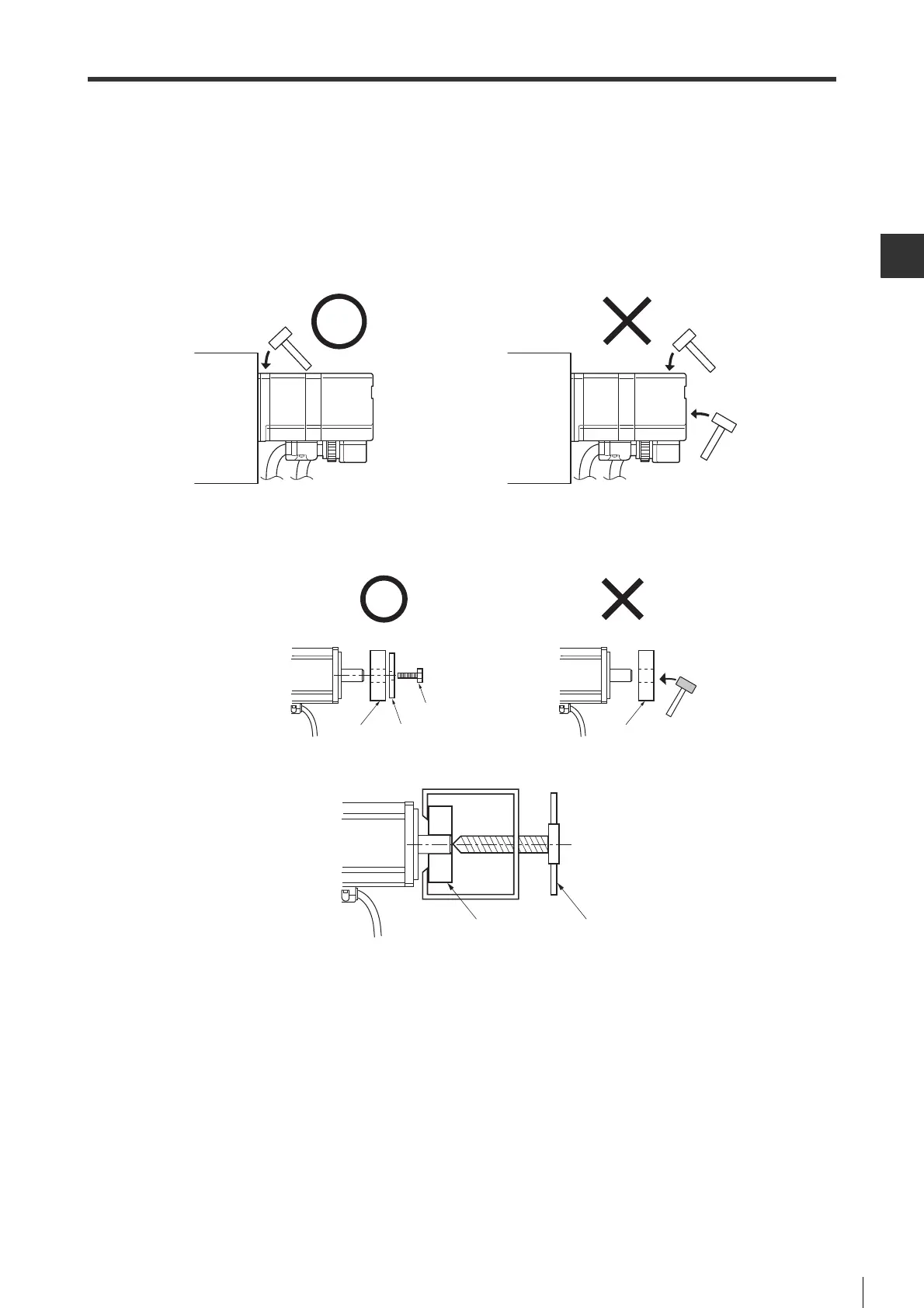

Direct shock to the shaft isn't allowed when coupling is installed on servo motor.

If necessary, servo motor must be knocked with rubber or plastic hammer etc., and it is preferable to knock the front

flange part of servo motor.

High-precision installing holes must be machined for smooth connection when servo motor is installed on a machine.

In addition, the installing surface must be flat, otherwise, the shaft and bearings will be damaged.

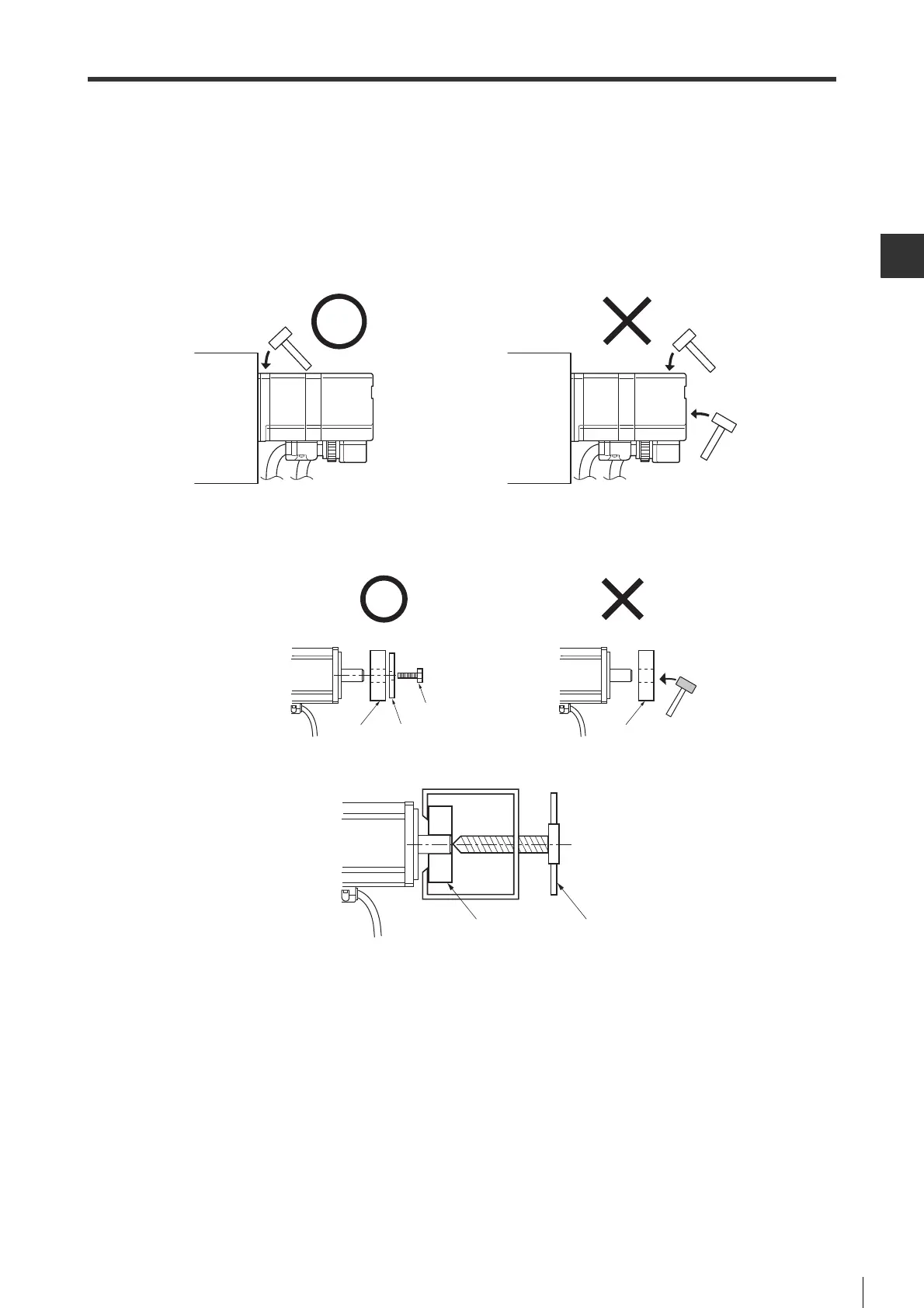

The screw hole at shaft end is preferred other than impact when gears, pulley or couplings are installed.

Special removing tool must be used when disassembling gears or pulley.

It is necessary to check that the shaft conversion value belt tension doesn't exceed the permissible value of radial

load when belt drive is performed.

FlywheelFlywheel Stopper

Bolt

Flywheel Removing tool

Loading...

Loading...