Image Adjustment

SM 4-257 D0CA/D0C9/D0C8/D0CB

&

Adjustment

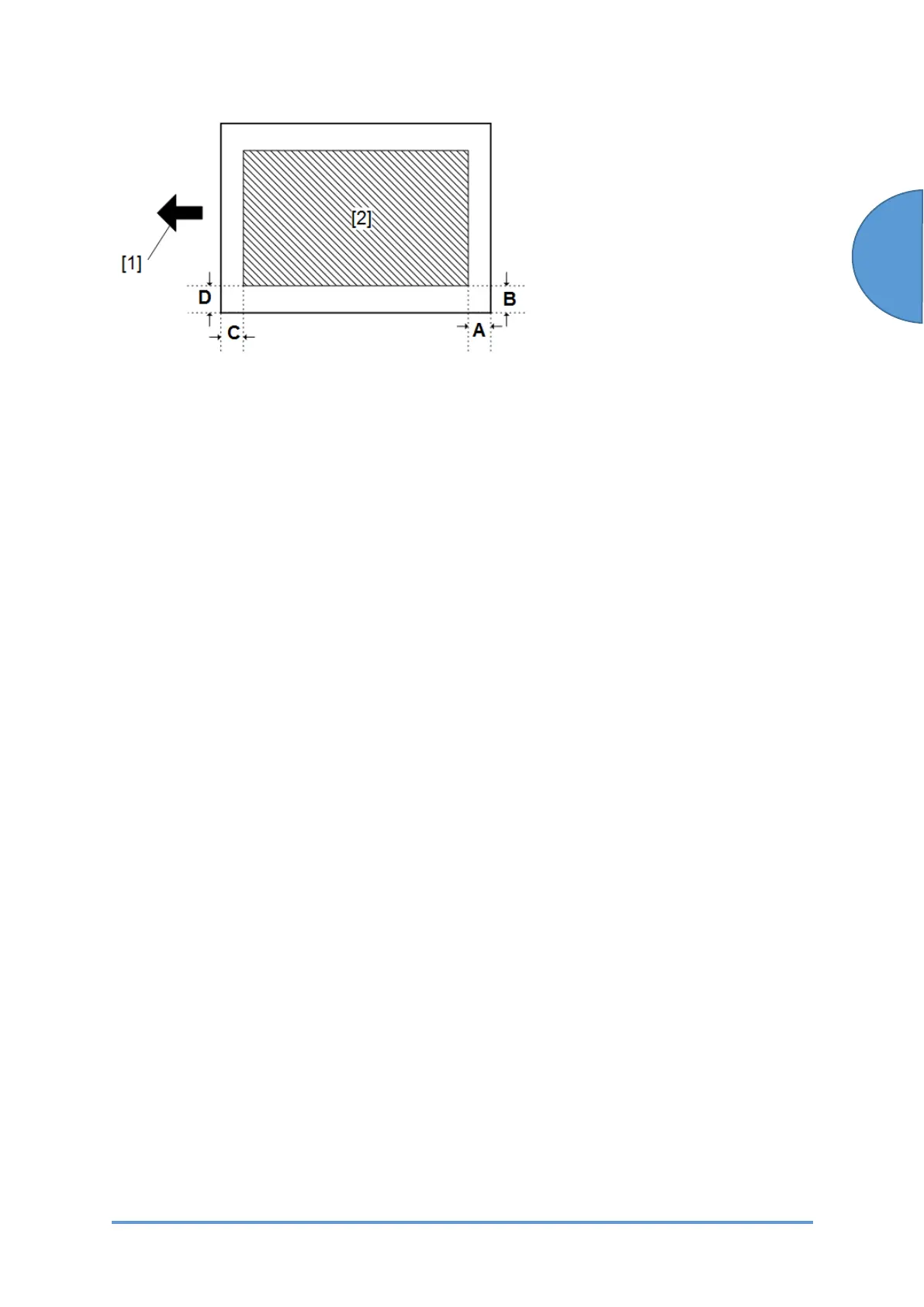

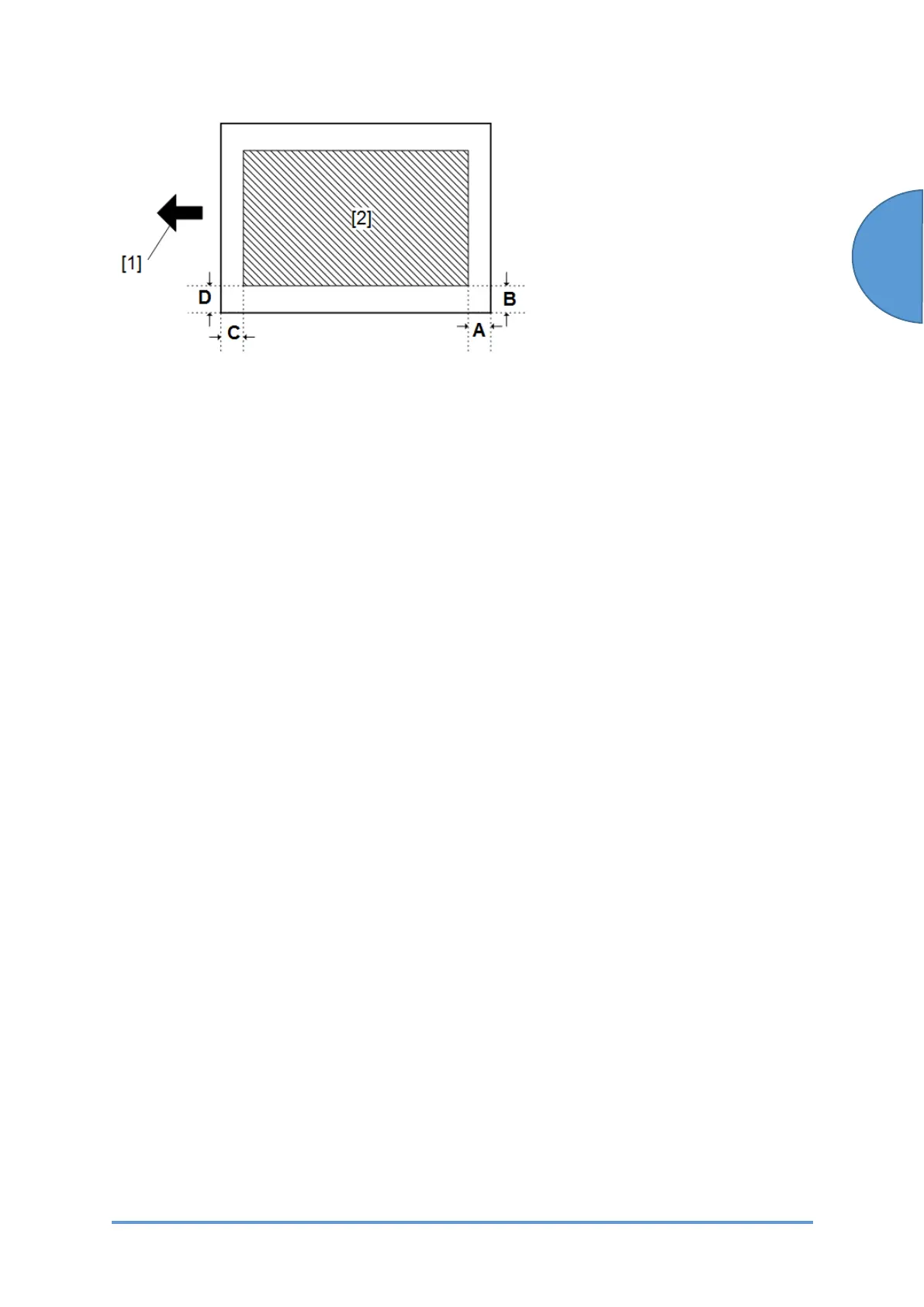

[1]: Feed direction, [2]: Image area

1. Enter the SP mode.

2. Print out the test pattern (14: 1-dot trimming pattern) with SP2-109-003.

3. Check the erase margin A and B. Adjust them with SP2-103-001 to -004 if necessary.

• Leading edge: 0.0 to 9.9 mm (default: 4.2 mm)

• Side-to-side: 0.0 to 9.9 mm (default: 2.0 mm)

• Trailing edge: 0.0 to 9.9 mm (default: 4.2 mm)

4.20.6 COLOR REGISTRATION

Line Position Adjustment

The automatic line position adjustment usually is done for a specified condition to get the best

color prints.

Do the following if color registration shifts:

• Do "Auto Color Registration" as follows to do the forced line position adjustment.

1. First do SP2-111-003.

2. Then do SP2-111-001.

To check if SP2-111-001 was successful, watch the screen during the process. A message

is displayed at the end. Also, you can check the result with SP2-194-010 to -012.

• You should also do the line position adjustment at these times:

• After you transport or move the machine (you should do the forced line position

adjustment if you install the machine at the user location) if the machine is

pre-installed at the workshop and moved to the user location,

• When you remove or replace the motors, clutches, and/or gears related to the

drum/development/transfer sections

• When you remove or replace the image transfer belt, image transfer belt unit or laser

optical housing unit

Loading...

Loading...