Toner Supply Section

SM 7-53 D0CA/D0C9/D0C8/D0CB

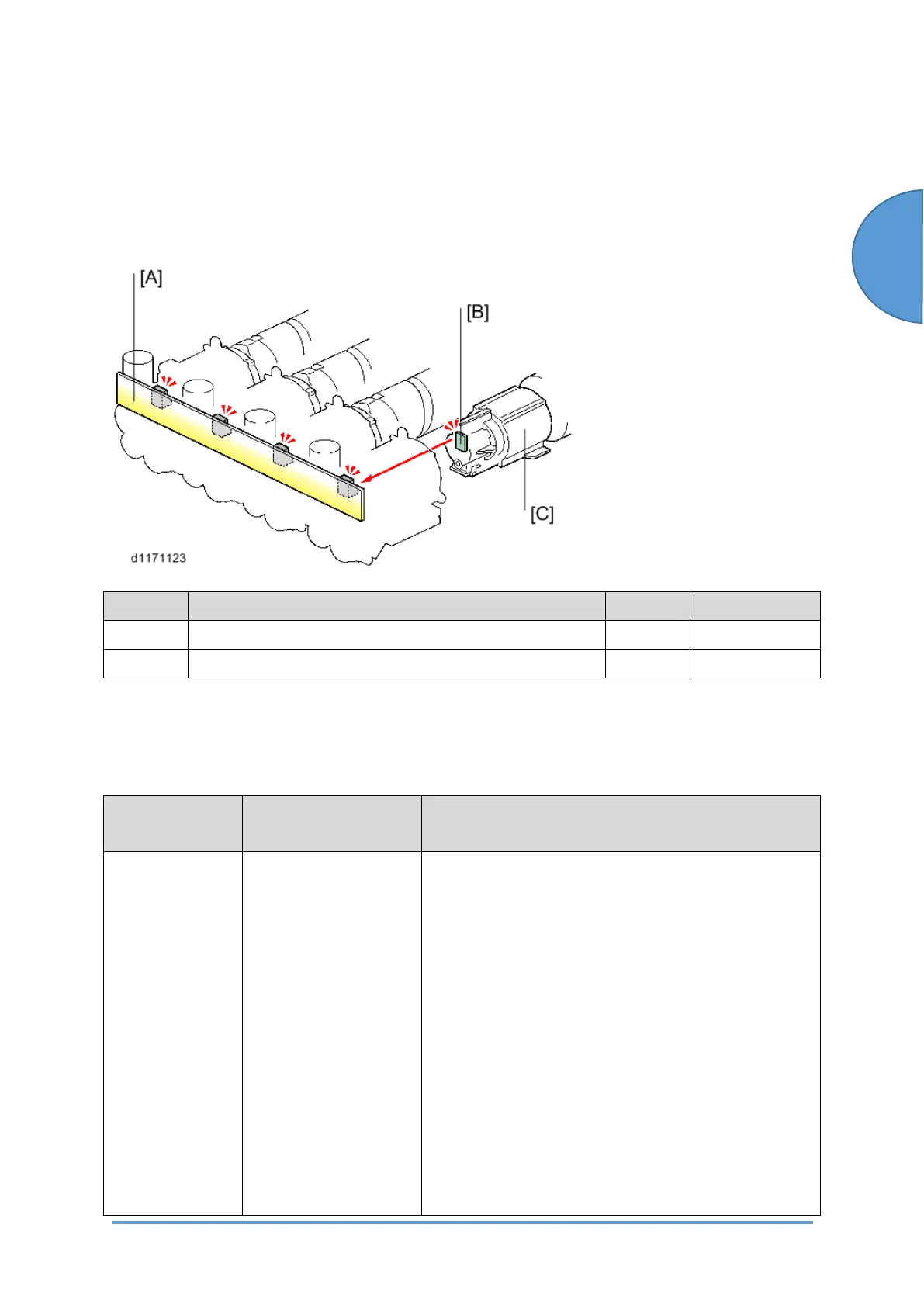

7.7.3 TONER BOTTLE SET SENSOR MECHANISM

Each toner bottle [C] has an ID chip (PCB3-PCB6) [B]. When the toner bottle [C] comes in

contact with the toner bottle sensor board (PCB7) [A], the machine detects that the toner bottle

is set.

Callout Item Callout Item

[A] Toner Bottle Sensor Board (PCB7) [C] Toner Bottle

[B] ID Chip (PCB3-PCB6) (One for Each Color)

7.7.4 TONER NEAR END/END DETECTION

The following table shows the conditions to detect when the toner has run out (Toner End) or

almost run out (Toner Near End) and the operations following the detection.

Status Operation panel

message

Detection conditions

Toner Near End

SP3-101-001 to

004="1"

Operation panel

banner display:

<Toner Cartridge is

empty.

Printing will be

suspended soon.

Replace the

cartridge.>

Toner Near End is detected by the following 2

systems:

(1) Toner Near End detection by Toner End sensor

(S11-S13). (Definite Toner Near End)

(2) Toner Near End detection by referring to pixel

count and total counts by toner supply motor

(M1-M4) (Estimated Toner Near End)

The Toner Near End detection system is determined

according to the Toner Near End Detection System

(SP3-100-002) setting.

If SP3-100-002 is set to "0": Both detection systems

are applied.

If SP3-100-002 is set to "1": Only (1) is applied.

Loading...

Loading...