VA Motion Controller Programming Manual

123

(

1

) Project creation and configuration

For the convenience of use, our company has equipped the user with a template

project for

CANopen

communication configuration. Users can go to the official website to

downloaDAnd directly program on the basis of the template project. ( The template default

configuration of a shaft, can be configured up

. 1 . 6

axes, may be addeDAs required in the

configuration template )

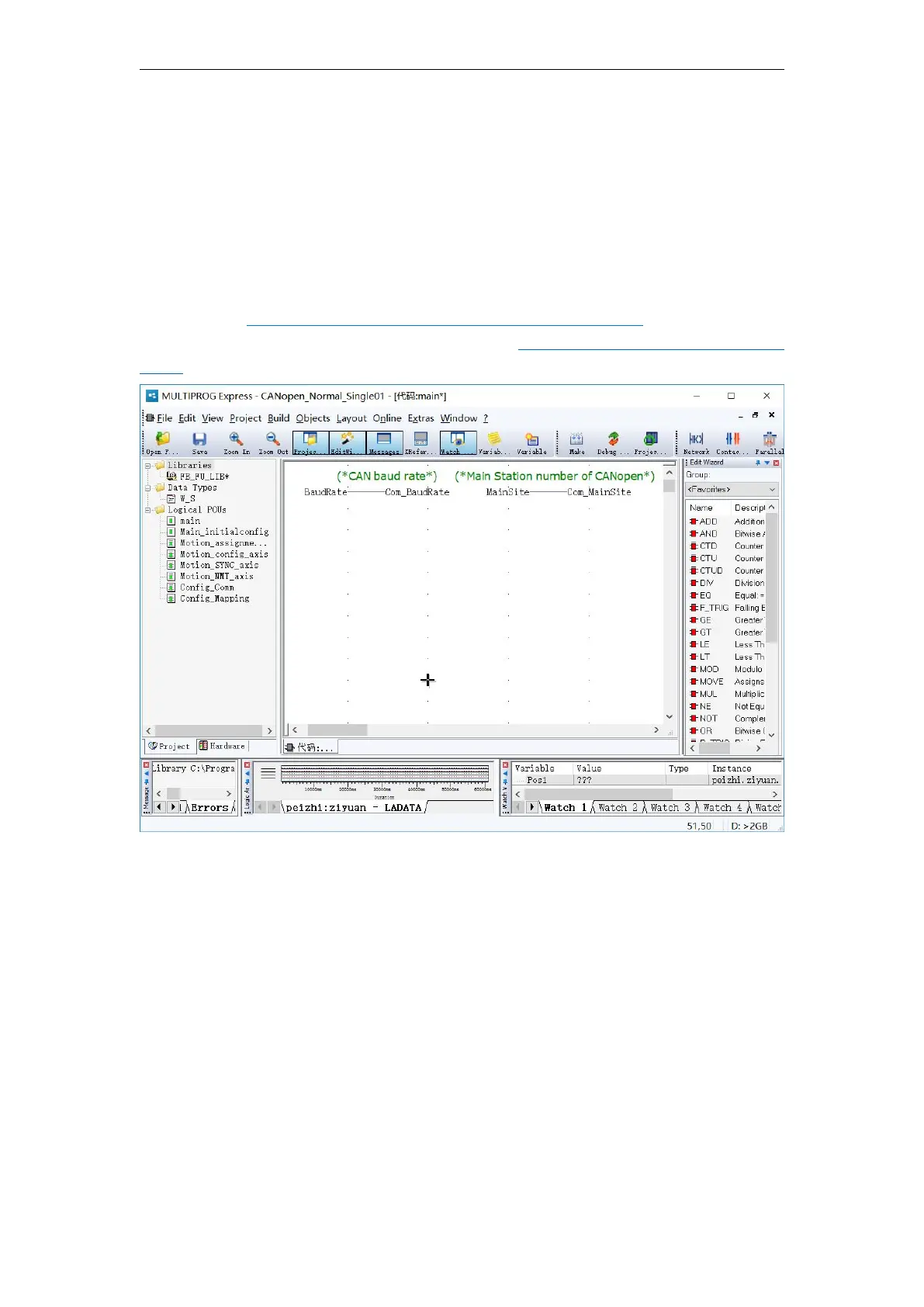

Once you have downloaded the template, extract the open, in the following figure ,

the reference to Chapter VII of the creation and configuration of the project to complete the

PC

to

communicate with the motion controller, and reference 11.1 insert FB_FU_LIB motion control

library complete adding a library, which will not be repeated herein .

Note: The template default

CANopen

master station number is

1 8

and the

CAN

bus baud rate

is

8 00

(corresponding to the

CAN

bus baud rate set by the servo driver

P 08.40

), which can be

modified by modifying the initial value of the

BaudRate

.

(

2

) node configuration

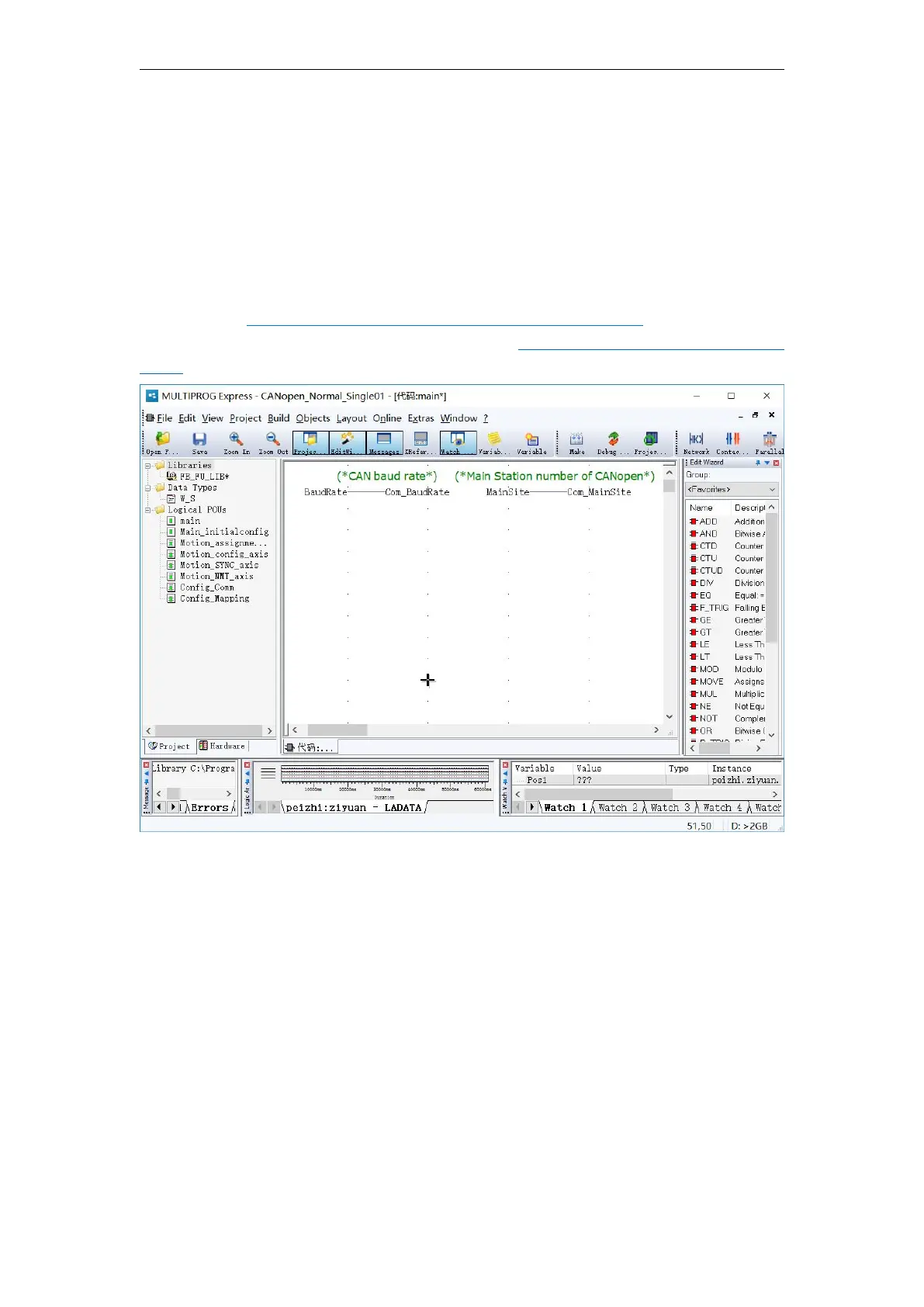

Step 1: Since the template configures one axis by default (node number is 1 ), and two

axes are used in this case, we need to manually adDAnother axis in the configuration template

(node number is set to 2 ). Double-click " Main _initialconfig " under "Logical POU " in the

project tree to open the configuration flow program of

CANopen

communication (you can close

the window management button in the upper right corner when you need to close), as shown

below.

The maiNSteps of the configuration can be seen in the figure: master-slave node reset

(

R estnode

), master-slave node enters pre-operation mode (

Motion 402 _ assignment

),

configures master-slave node synchronization cycle and master-slave node process data

Loading...

Loading...