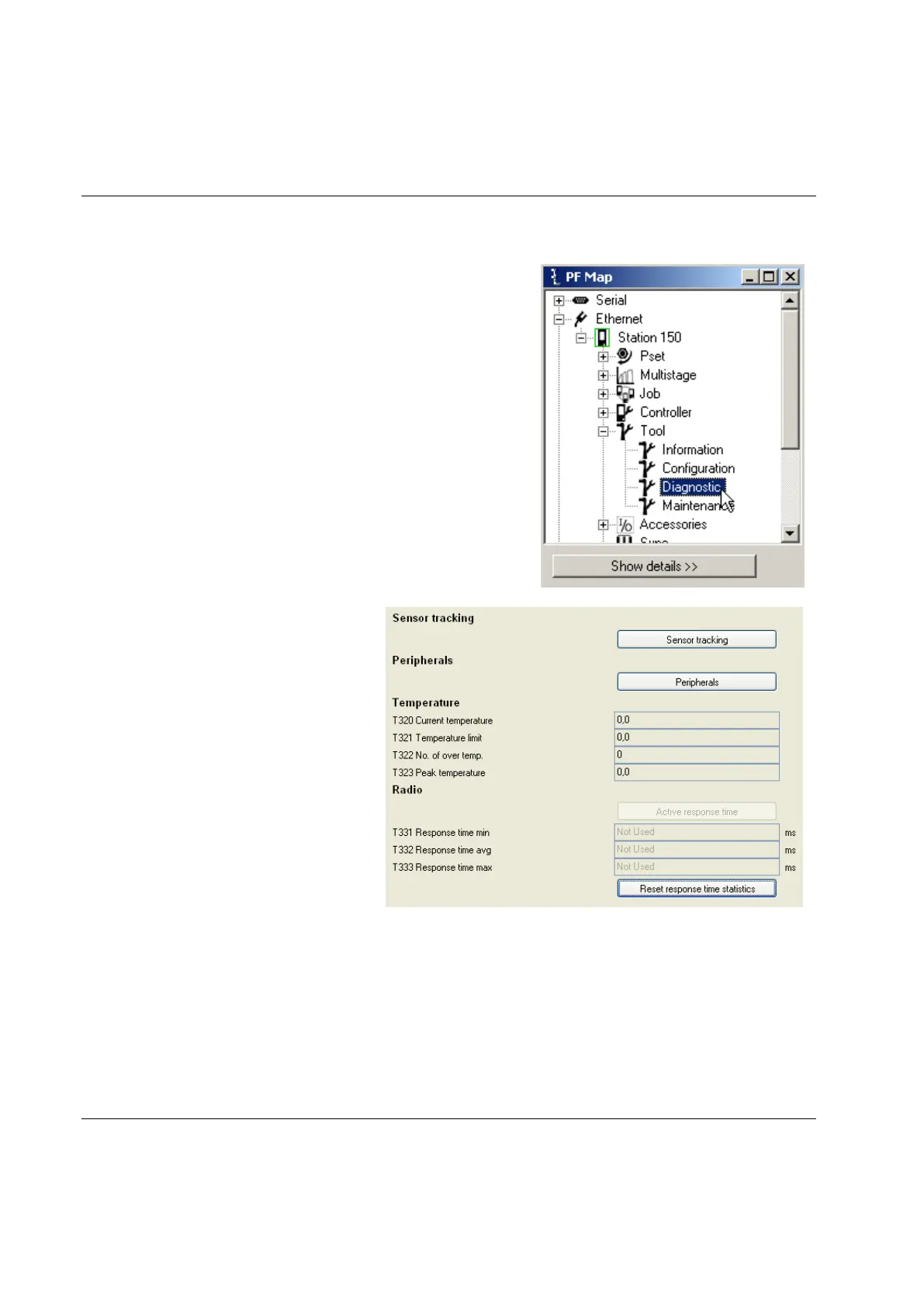

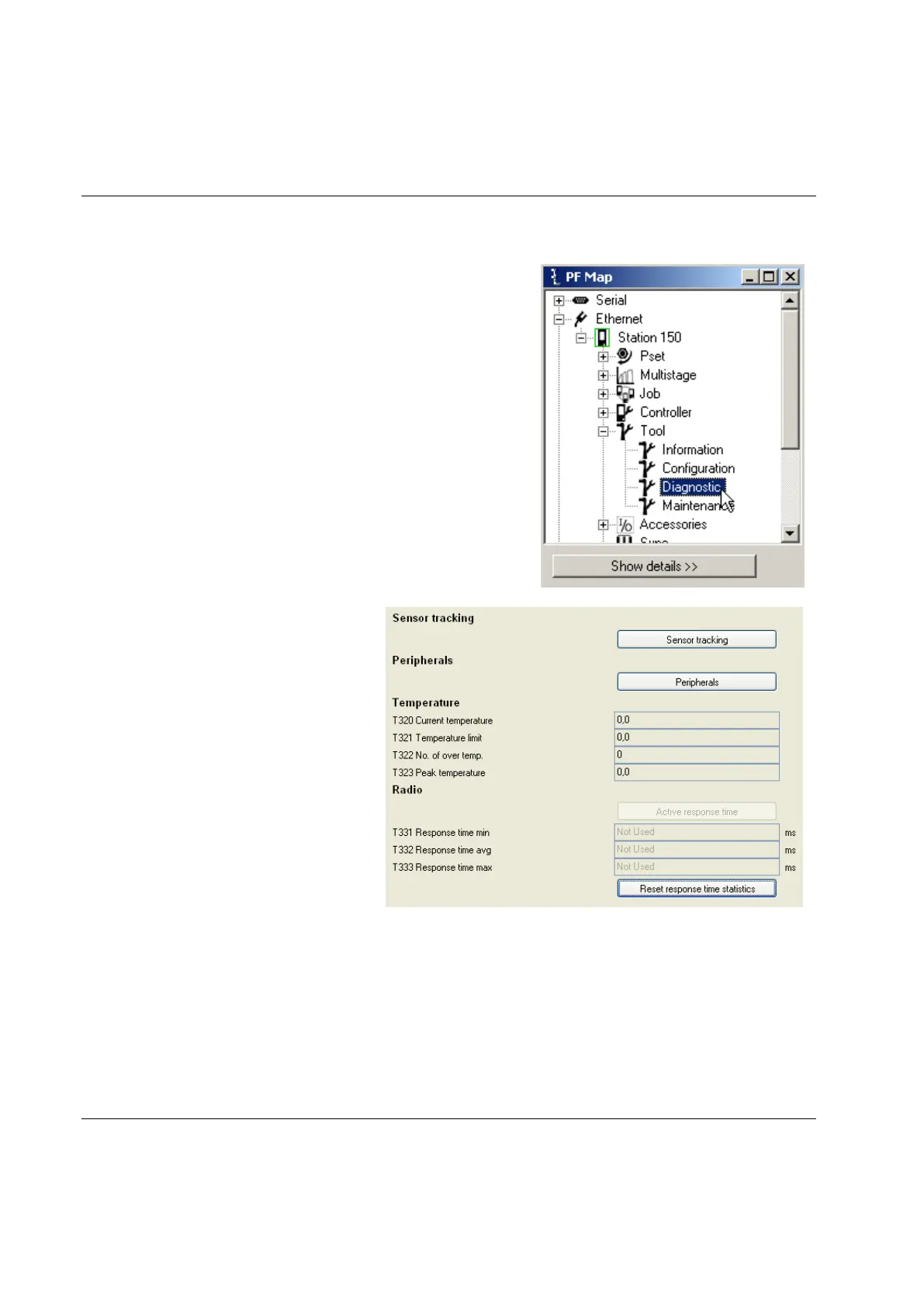

Click Sensor tracking to introduce torque

and angle readings in real time.

Click Peripherals to diagnose tool LED's

and buttons.

Temperature parameters are for

information only.

Click Active response time under Radio to

diagnose the wireless connection.

Loading...

Loading...