Tool

9836 3123 01 155 (428)

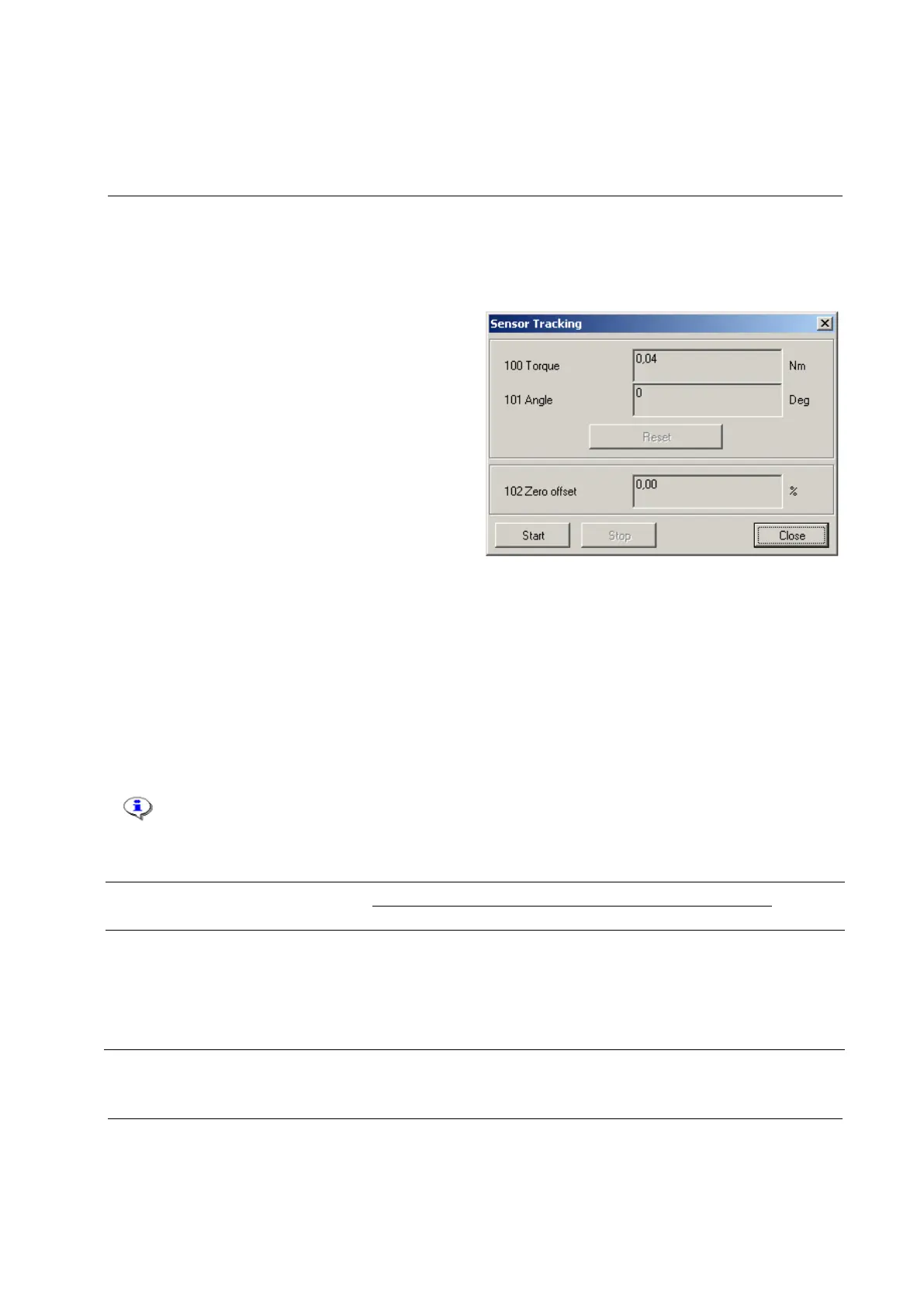

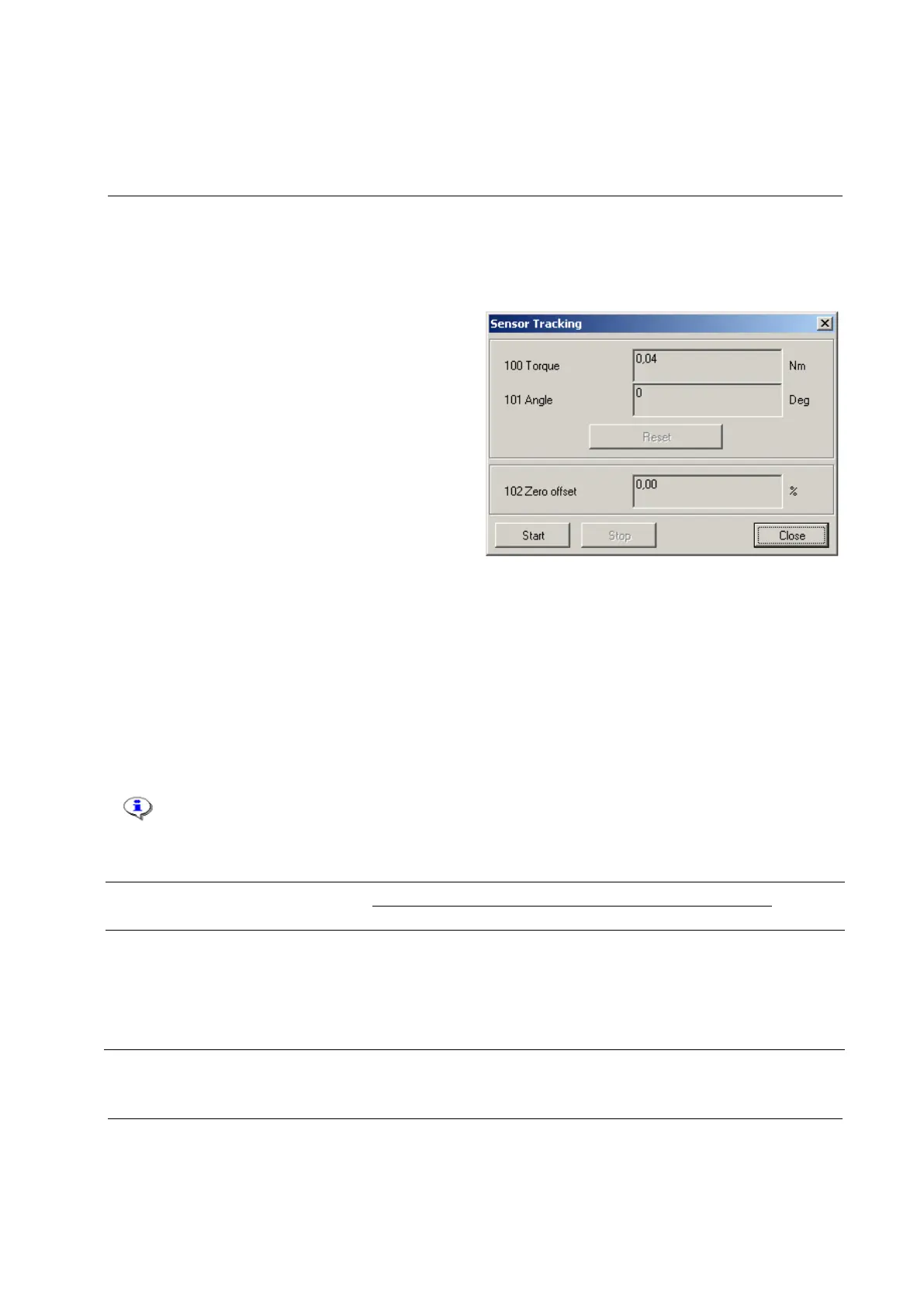

11.3.1 Sensor tracking

To monitor Torque/Angle readings from the

tool press Start. To set reference point for Angle

value during monitoring press Reset.

For S, DS tools it is even possible to read value

of the transducer offset shown in percentage of

the nominal torque range.

For other tool families this parameter is not

accessible (always set to 0.00%).

11.3.1 Transducer calibration

When tool is triggered, a check of transducer and transducer electronics is carried out. Results

(offset and gain) are sensitive to temperature, material wear and even proper handling of tool

during calibration. Don’t manually rotate gear when tool is triggered to obtain most accurate

transducer readings. If program discovers offset or gain values being out of correction limits or

that these parameters have changed too much since last calibration, the corresponding event

(E544) will be displayed and rundown will be aborted. Following table shows these limits for

different type of tools.

As long offset and gain change is not caused by fast, manual rotation of the gear during

triggering of the tool, even relatively big offset and gain changes are completely

compensated in the system, not having influence on specified measurement accuracy.

Offset range (% nominal torque)

Offset change (+-% nominal torque)

Gain* range (% nominal gain)

Gain* change (+-% nominal gain)

Nominal gain* (% nominal tq)

Loading...

Loading...