The rehit functionality is designed to detect re-tightenings of an already tightened joint, thereby avoiding

batch counting errors etc. Two parameters have been found to be good indicators of a so-called rehit, tool

speed and tightening angle. If, for two stage torque control tightenings, the tool does not get up to speed

before the first target occurs and the angle of the second stage is not great enough the rehit alarm is

activated.

For two stage torque control tightenings, the speed must reach more than ¼ out of P131 Step 1 speed

between P110 Cycle start and P111 First target or the angle between P111 First target and P113 Final target must

be greater than 120 degrees to avoid a rehit alarm. For one stage tightenings, the speed at P110 Cycle start

and the angle between P110 Cycle start and P113 Final target are used as indicators.

The large angle interval required means that for most normal tightenings it is the speed condition that is

met. Only for very soft joints with a low P111 First target or one stage tightenings is the angle condition met.

For two stage angle control tightenings, the rehit alarm is activated if the tightening is aborted on P114 Final

tq max and the tool speed has not reached ¼ of the P131 Step 1 speed between P110 Cycle start and P111 First

target. For one stage tightenings, the speed at P110 Cycle start is used as indicator.

The rehit functionality is valid for most, but not all, control strategies.

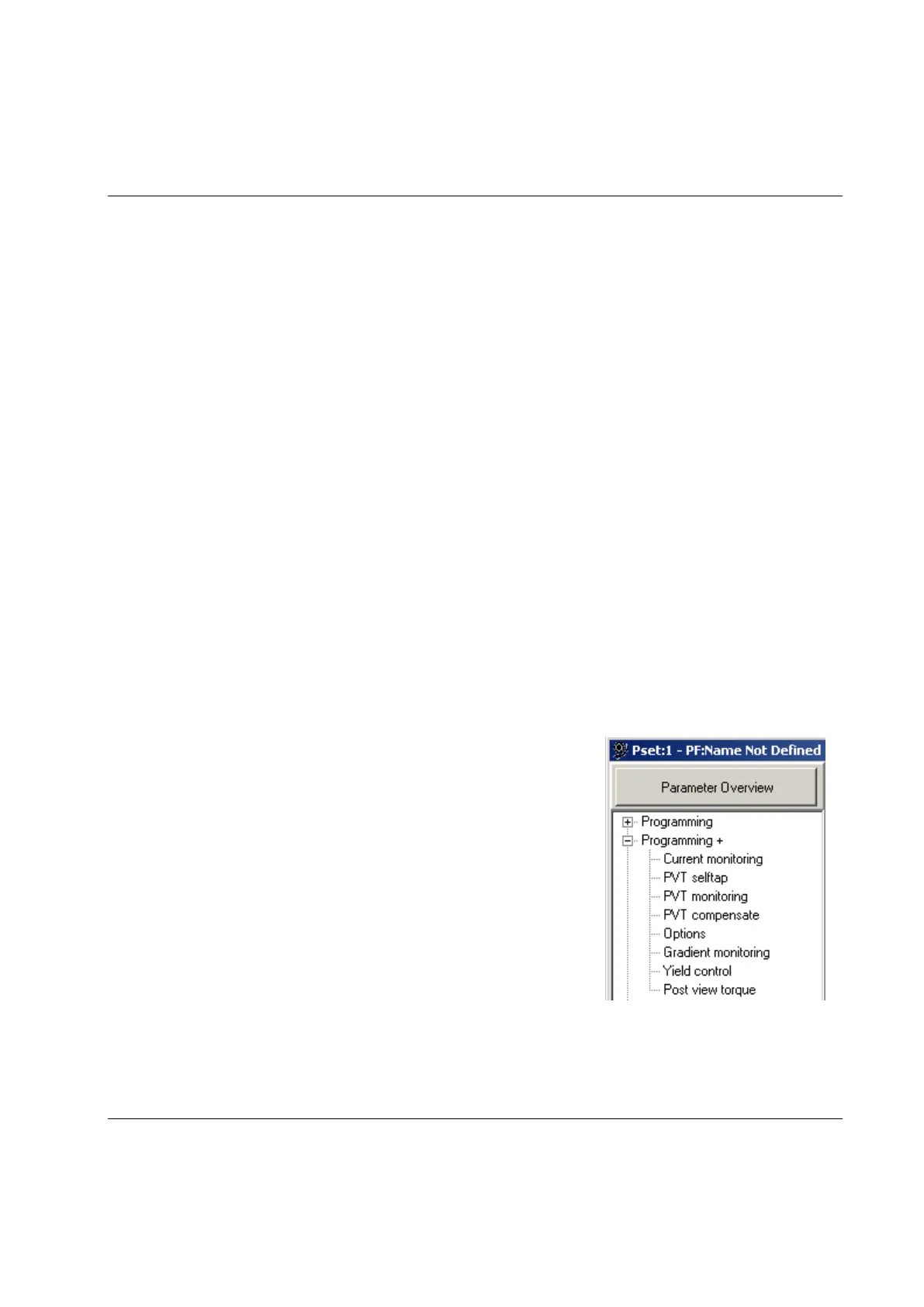

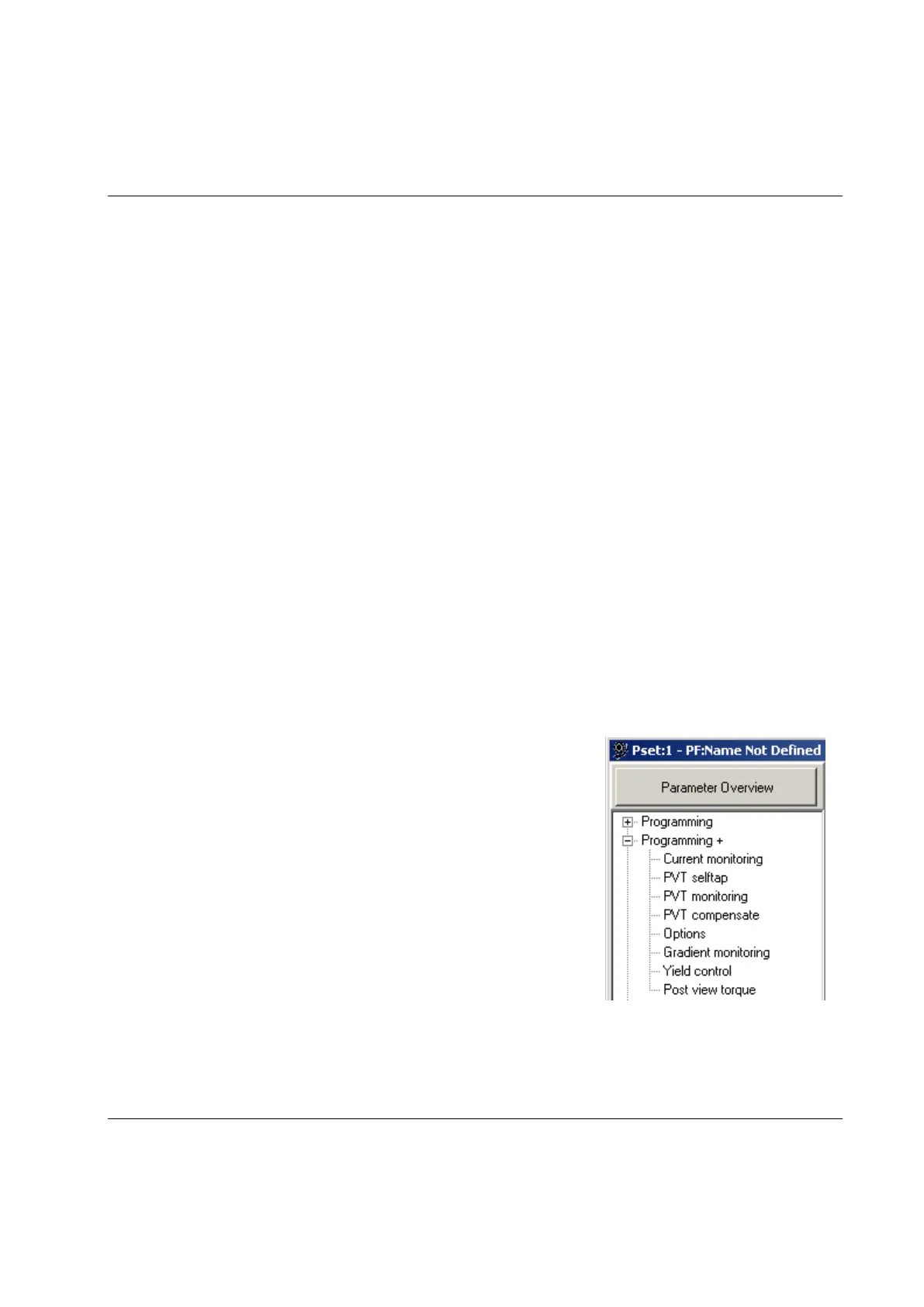

Expand the Programming + branch.

This section has applications for additional Pset functionality.

The Current monitoring includes parameters regarding the motor

current.

PVT selftap includes settings when the joint has a torque peak at the

start of the tightening.

PVT monitoring include settings where the prevailing torque during the

rundown phase is monitored, and PVT compensate settings where it is

included in the calculation for the target torque.

The PVT options can be used together or independently of each other.

The Options window includes settings for tool tightening direction and

some alarm settings, for example.

Loading...

Loading...