Sync allows a group of spindles to perform the same task simultaneously. Examples where a

Sync solution could be applicable are the tightening of car wheels and the tightening of

cylinder head bolts. The Sync function is RBU-dependent.

This section includes screenshots from ToolsTalk PF. The screenshots show examples of

parameter settings and are NOT intended to be generally applicable. Check with your

local Atlas Copco representative how to set up your specific system environment.

See parameter list section Sync for a description of all available Sync options.

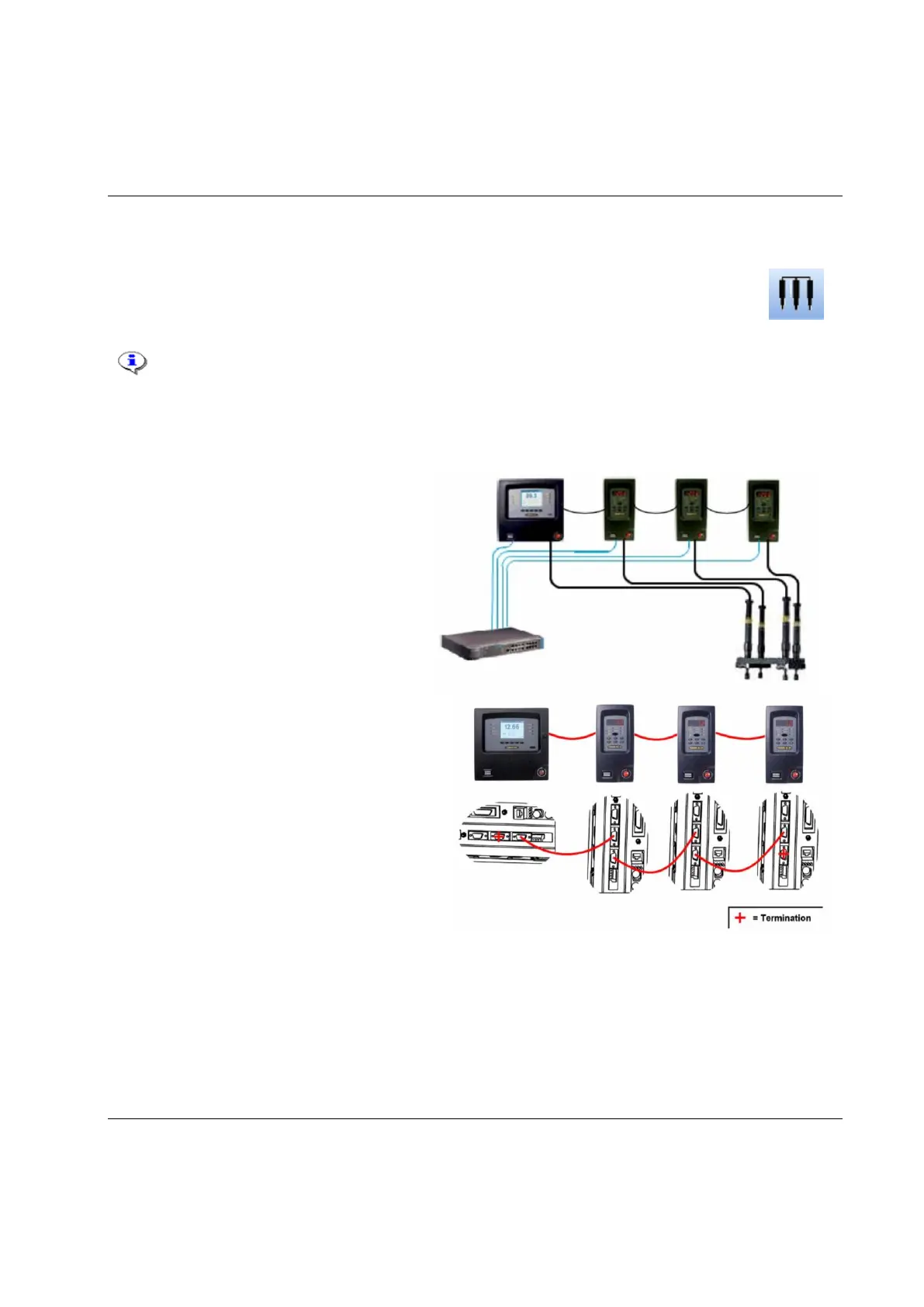

A Sync group consists of PF units working in

the same Cell.

One of the controllers is defined as Sync

reference. The other controllers are Sync

members.

The Sync reference handles the

Synchronization between the tools, the

selection of Psets and the result reporting for

the Sync. A Sync group can be viewed as one

PF with more than one tool.

A Sync group can be part of a Job (see

chapter Job). Note that it is the Job reference,

and not the Sync reference, that counts the

batch in a Job with Sync.

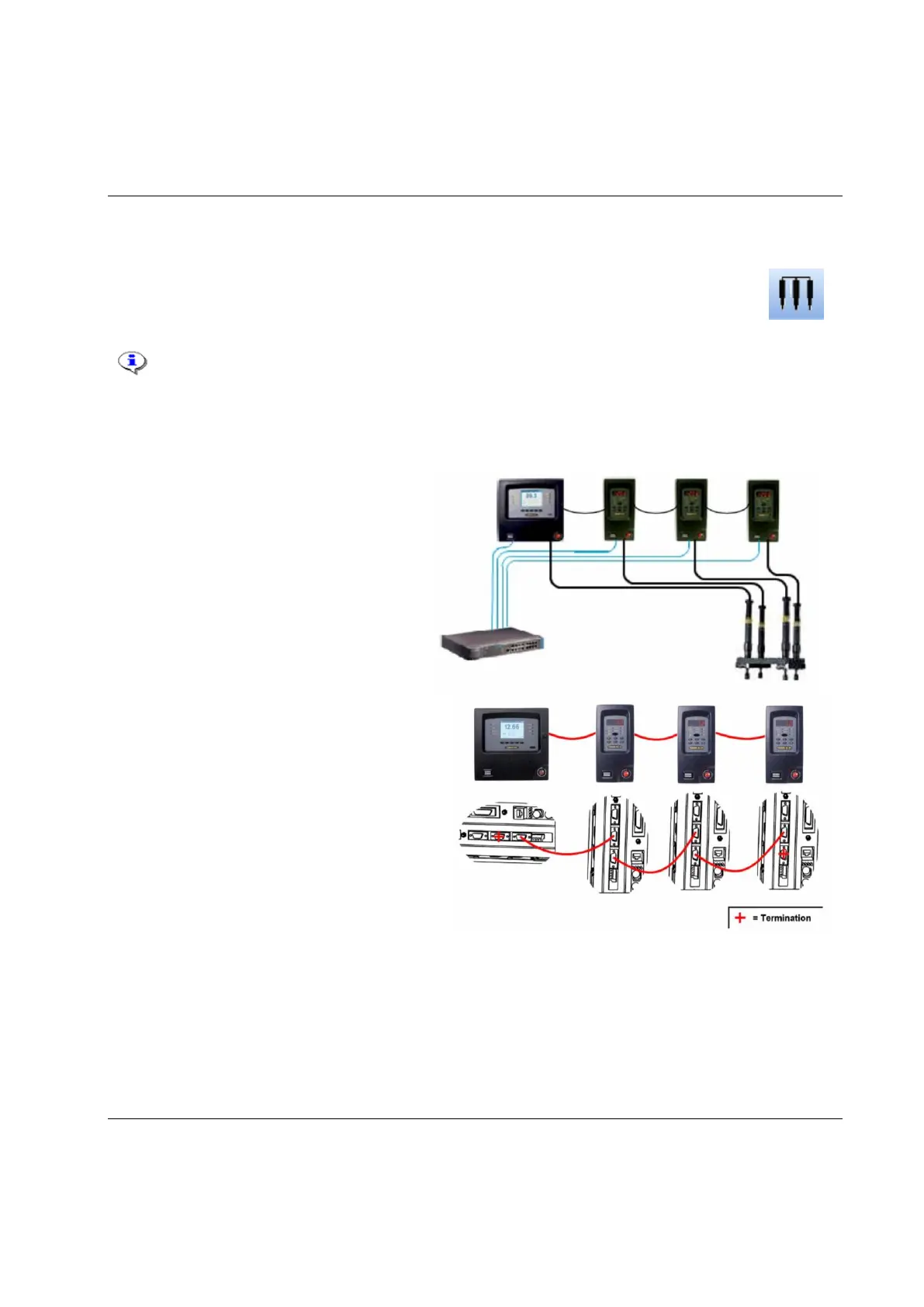

The status information on each controller and

tool shows the individual result for that

spindle. The overall Sync OK/NOK can be

given on the fieldbus, RE-Alarm or relays

controlled by the Sync reference. The results

from every spindle are registered separately.

The status from individual Sync members

can be viewed on the Sync reference

controller.

Sync is performed in steps or SynchroTork (PF4000 only). In step Sync, all Synchronized spindles wait

for each other at a number of checkpoints before they continue with the next step. A typical two stage

tightening has checkpoints at P111 First target and P113 Final target. SynchroTork allows continuous

Loading...

Loading...