The set of parameters that controls the tightening process is contained within a Pset. This

section describes how to setup the basic parameters necessary to perform a tightening. Create a

Pset by using Autoset, Quick programming or by setting the parameter values manually using

PF Graph or ToolsTalk PF.

This section includes screenshots from ToolsTalk PF. The screenshots show examples of

parameter settings and are NOT intended to be generally applicable. Check with your

local Atlas Copco representative how to set up your specific system environment.

See parameter list section Pset for a description of all available Pset options.

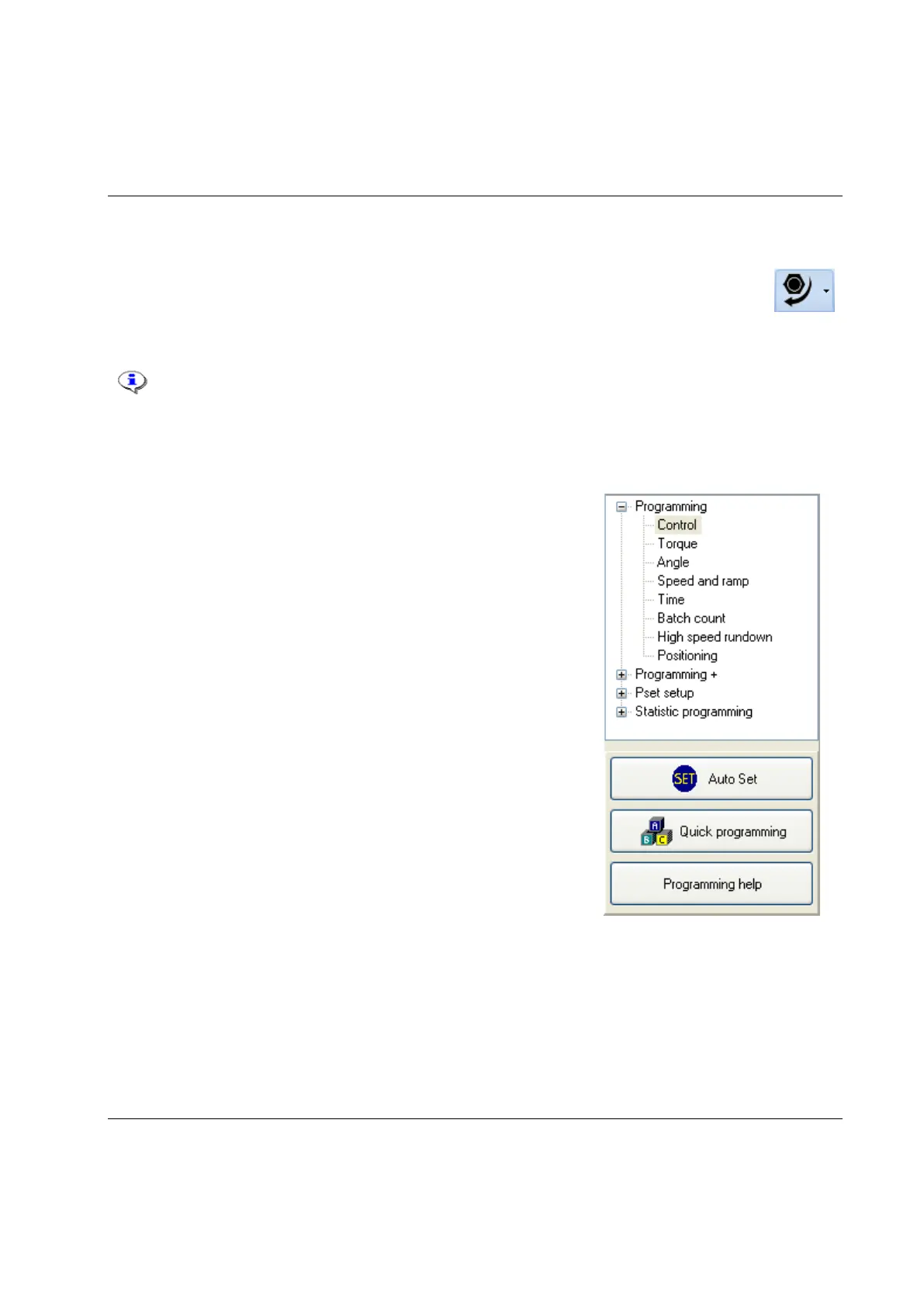

The basic Pset parameters are located under the Programming branch:

Control

Torque

Angle

Speed and ramp

Time

Batch count

High speed rundown

Positioning

Additional settings are found under Programming+, Pset setup and

Statistic programming.

An easy way to program a Pset is to use the Autoset function.

Quick programming is intended to help users to quickly configure a

Pset. After completing a Quick programming procedure, the tool is

ready to use for tightening.

Programming help shows an image of the selected strategy.

Every time a Pset changes, the ID of the person changing the Pset is

stored in P409 PSet updated by. This information is useful for tracing

who has made the last change in any given PSet. If no user has logged

in the filed values are: TTPF if changed via ToolsTalk, OPER if

changed via the controller, and BLANK if the Pset has been created in

an earlier version of the software. (For being able to log users this

functionality requires a special SW called ToolsUserAdmin, which

handles the access level for users via TTPF.)

Loading...

Loading...