Tensor STB communicates with the tightening controller systems through wireless digital communication,

built on IRC (Industrial Radio Communication) technique.

Tensor ST tools communicate with controllers through digital communication, allowing new tool features

and greater flexibility due to not so many wires and leads. Compared with a Tensor S tool, it is also

lighter with improved accessibility.

Tensor SL is a range of low torque transducerized tools based on Tensor ST technology.

Tensor S tools are available in different configurations and motor types. Fixtured applications can easily

be installed and integrated with standard Atlas Copco components.

The ultra-compact ETX tool is designed for fixtured applications.

Atlas Copco’s Tensor DS tools have no transducer. Instead of receiving an electrical signal from a strain

gauge, the tool derives the torque from several relevant parameters, such as voltage, speed, temperature

and current.

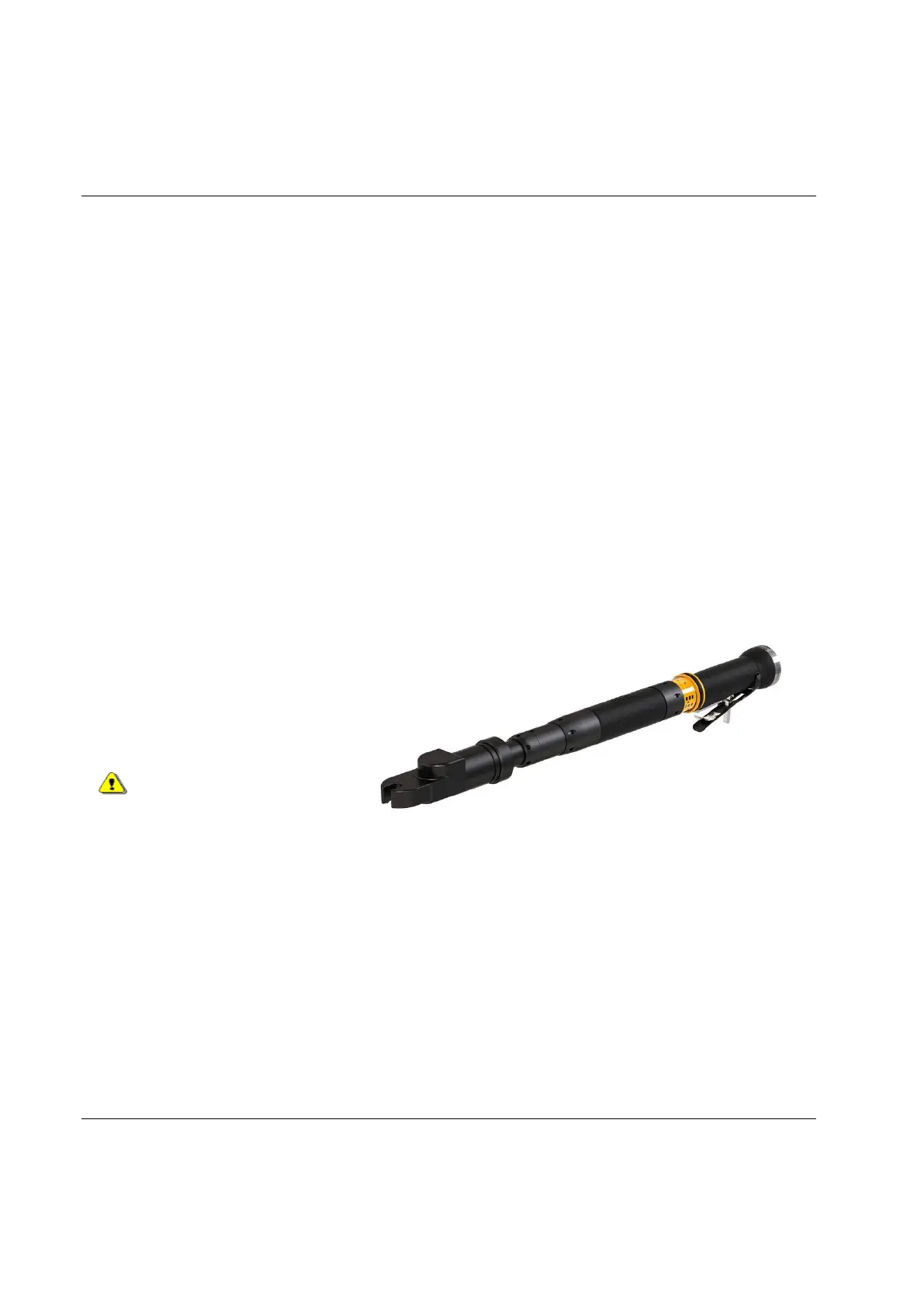

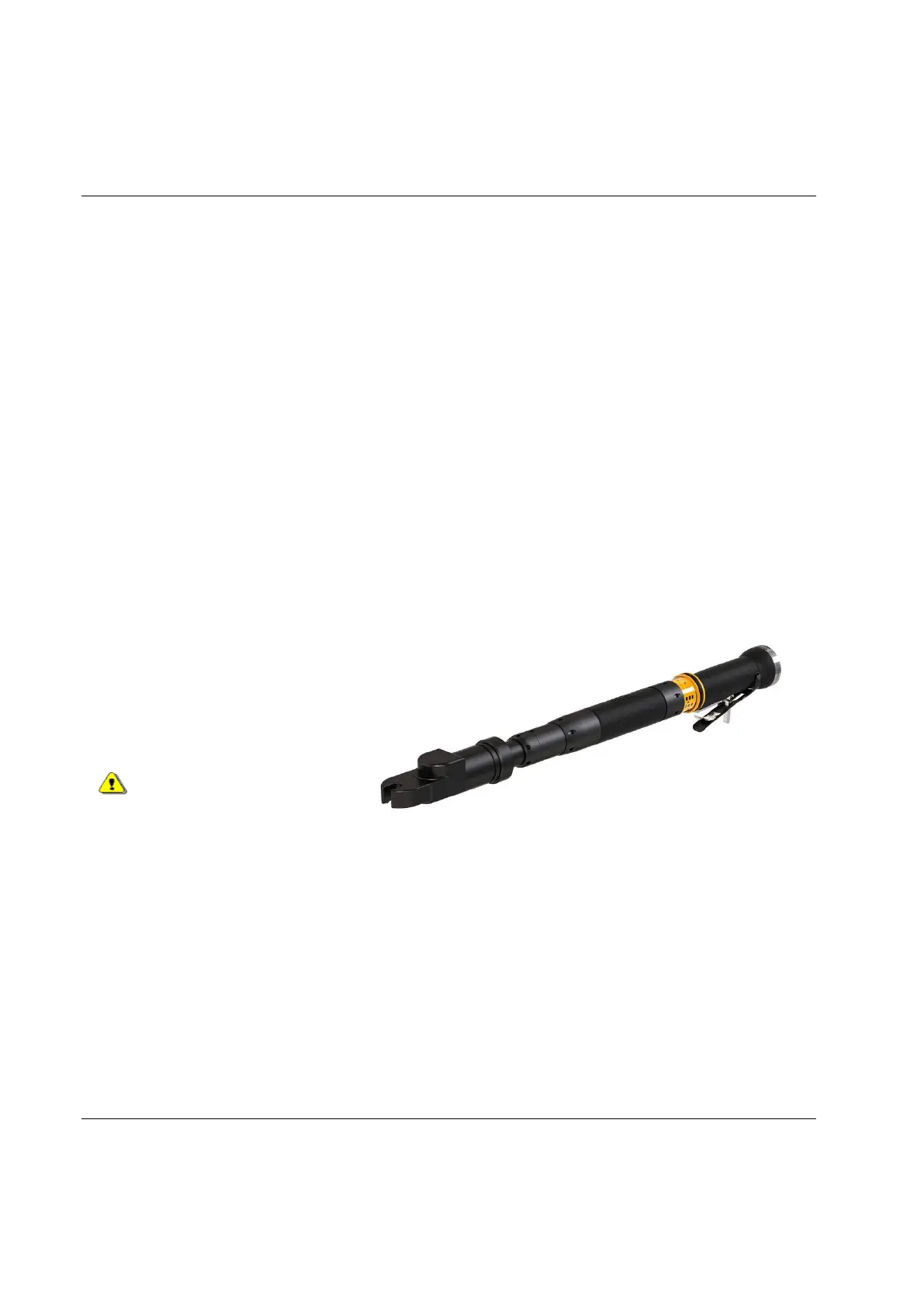

An open-end tool (or tube nut tool) is a

Tensor tool equipped with an open-

ended head. It is used to tighten nuts

on tubes and similar applications. The

open-end is available for several, but

not all, tools.

Loading...

Loading...