This tightening strategy is a development of

the existing PVT comp strategy described in

7.8.4. This strategy is useful when the PVT

comp torque level is higher than P113 Final

target.

The PVT compensate value is retrieved using

the Snug gradient method described above

for finding the snug point and then

calculating the torque compensate value

defined by following parameters.

P183 PVT distance: a point a defined

angle backwards from Snug point

P184 PVT interval: an angle interval

during which the comp value shall be

calculated

P185 Compensate value: option 'Peak' or

'Average' torque value within the

interval.

P186 Delay monitoring after cycle start: is a

parameter for filtering out a certain angle in

the beginning of a tightening where

monitoring for a certain 'gradient' is not

interesting. (Useful when the gradient is high

at cycle start etc.).

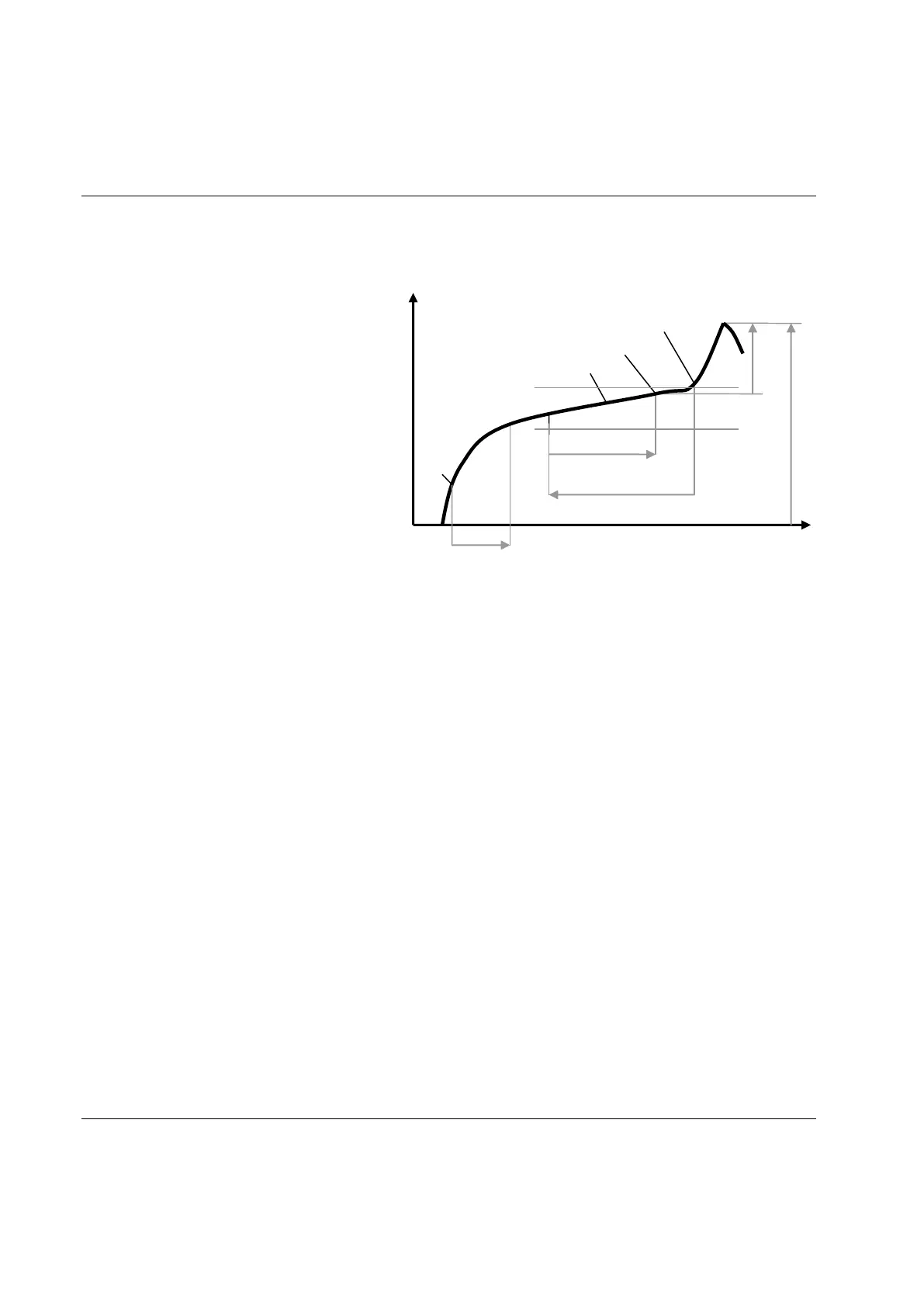

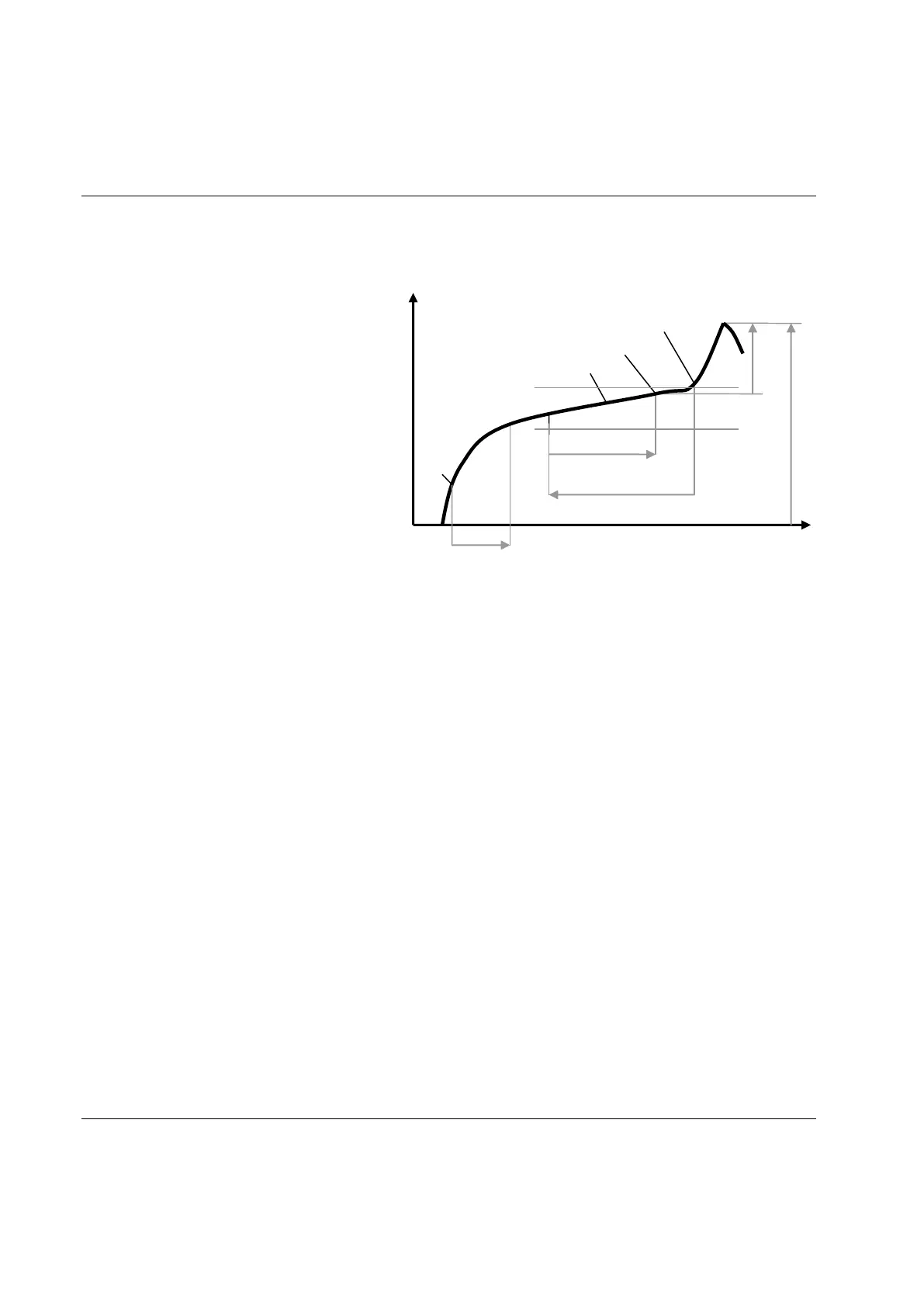

1. P186 Delay monitoring after cycle start

2. P184 PVT interval

3. P183 PVT distance

4. P113 Final target

5. Final target + PVT compensate value

6. P190 PVT min monitoring limit

7. P191 PVT max monitoring limit

After finding the snug point and the PVT comp value, the torque defined by P113 Final target is added to

the PVT comp value for reaching a total torque target. The achieved torque and the PVT comp value are

presented as in existing PVT comp strategy (i.e. dependent on C503).

If any of the torque values measured while searching after Snug point are lower than Snug PVT

monitoring min (P190) or higher than Snug PVT monitoring max (P191) the tightening shall stop when

Snug is found.

The presented final angle in the result is measured from the snug point.

Loading...

Loading...