This section is slated for expansion. Below are a few tips.

• Short Cut programming wizard has provisions for simple on/off control.

• PID control can be done with the CR1000. Ask a Campbell Scientific

application engineer for more information.

• When controlling a PID algorithm, a delay between processing (algorithm

input) and the control (algorithm output) is not usually desirable. A delay

will not occur in either sequential mode

(p. 527) or pipeline mode (p. 523),

assuming an appropriately fast scan interval is programmed, and the program

is not skipping scans. In sequential mode, if some task occurs that pushes

processing time outside the scan interval, skipped scans will occur and the

PID control may fail. In pipeline mode, with an appropriately sized scan

buffer, no skipped scans will occur. However, the PID control may fail as the

processing instructions work through the scan buffer.

• To avoid these potential problems, bracket the processing instructions in the

CRBasic program with ProcHiPri and EndProcHiPri. Processing

instructions between these instructions are given the same high priority as

measurement instructions and do not slip into the scan buffer if processing

time is increased. ProcHiPri and EndProcHiPri may not be selectable in

CRBasic Editor. You can type them in anyway, and the compiler will

recognize them.

7.9.17 Serial I/O: Capturing Serial Data

The CR1000 communicates with smart sensors that deliver measurement data

through serial data protocols.

Read More See Telecommunications and Data Retrieval

(p. 391) for background

on CR1000 serial communications.

7.9.17.1 Introduction

Serial denotes transmission of bits (1s and 0s) sequentially, or "serially." A byte

is a packet of sequential bits. RS-232 and TTL standards use bytes containing

eight bits each. Consider an instrument that transmits the byte "11001010" to the

CR1000. The instrument does this by translating "11001010" into a series of

higher and lower voltages, which it transmits to the CR1000. The CR1000

receives and reconstructs these voltage levels as "11001010." Because an RS-232

or TTL standard is adhered to by both the instrument and the CR1000, the byte

successfully passes between them.

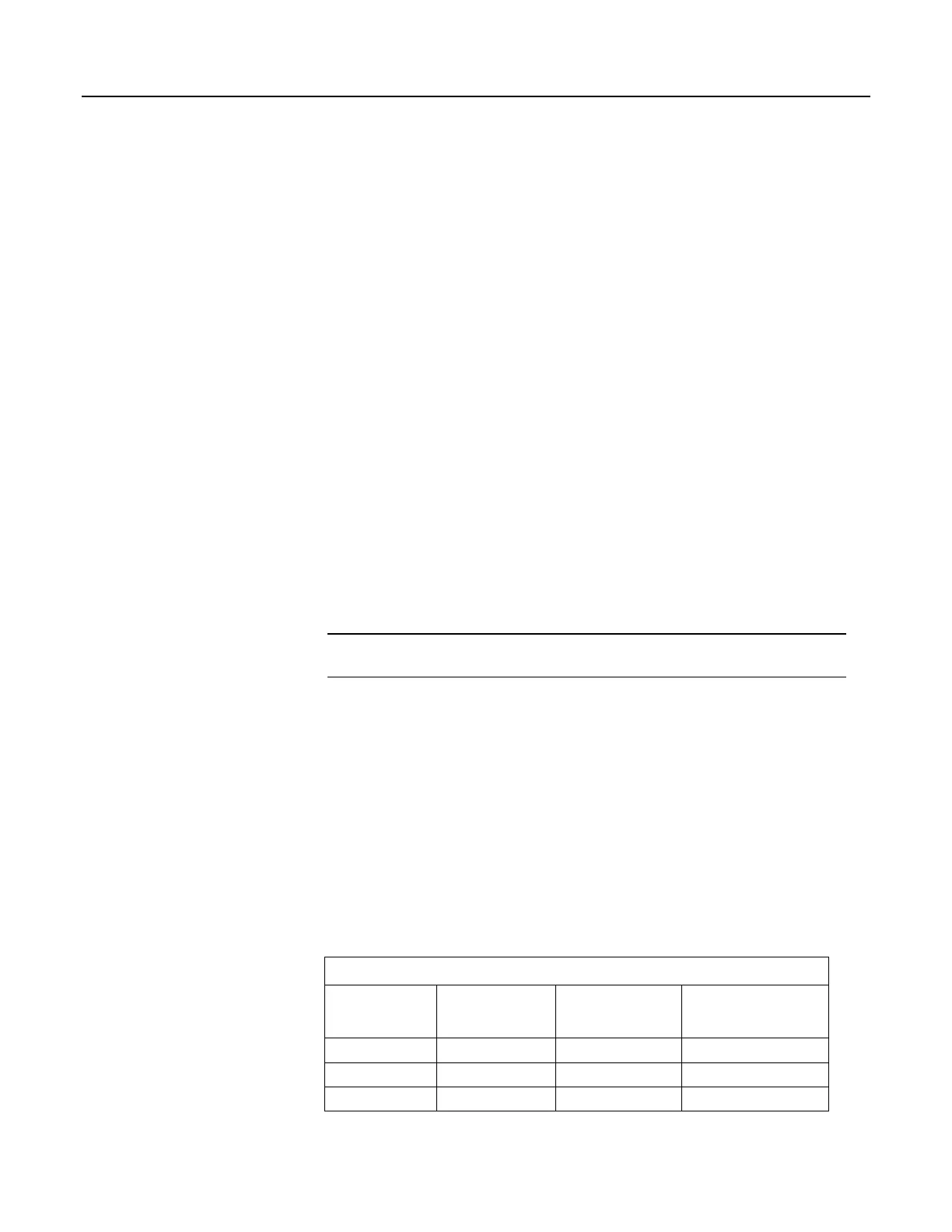

If the byte is displayed on a terminal as it was received, it will appear as an ASCII

/ ANSI character or control code. Table ASCII / ANSI Equivalents

(p. 245) shows a

sample of ASCII / ANSI character and code equivalents.

Table 41. ASCII / ANSI Equivalents

Byte

Received

ASCII

Character

Displayed

Decimal

ASCII

Code

Hex

ASCII

Code

00110010 2 50 32

1100010 b 98 62

00101011 + 43 2b

245

Loading...

Loading...