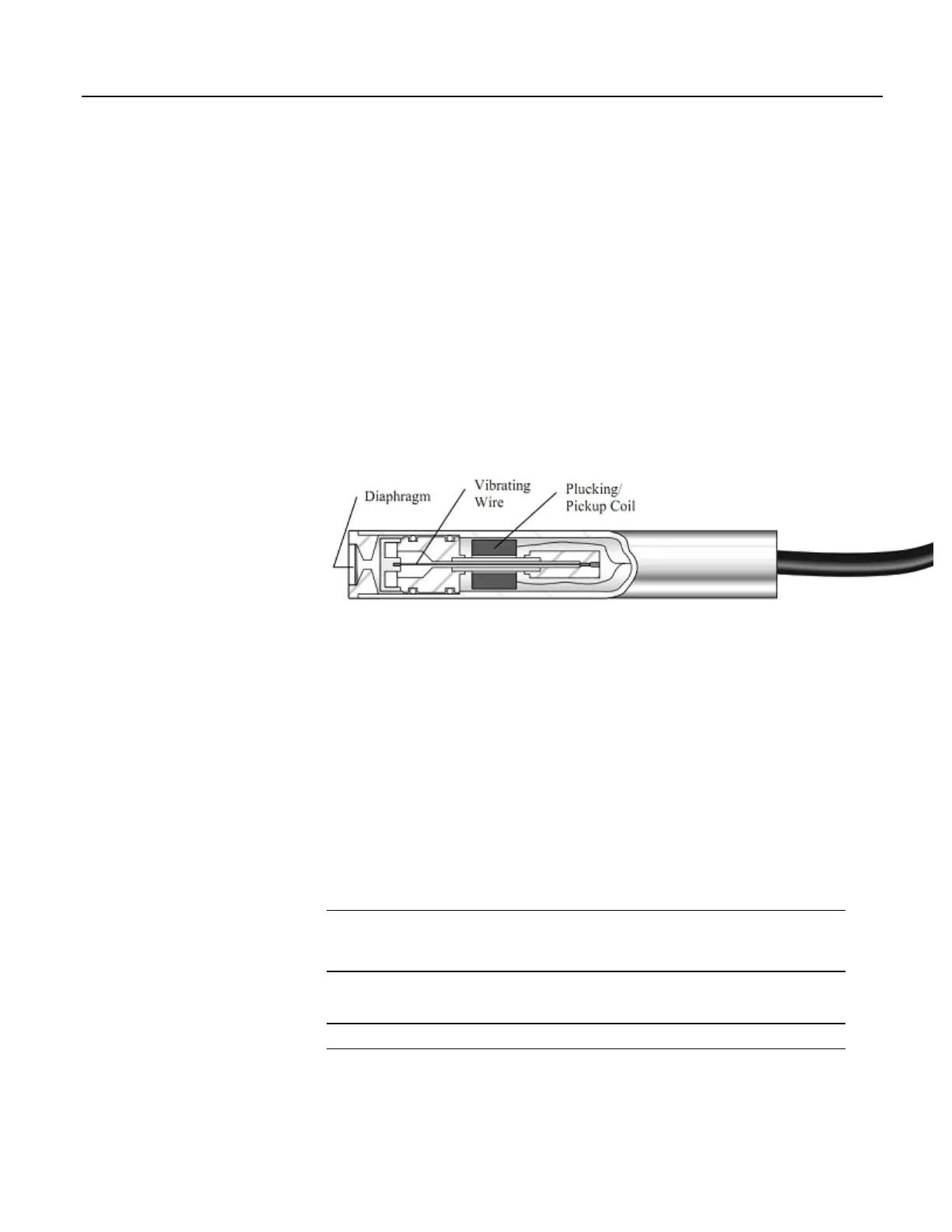

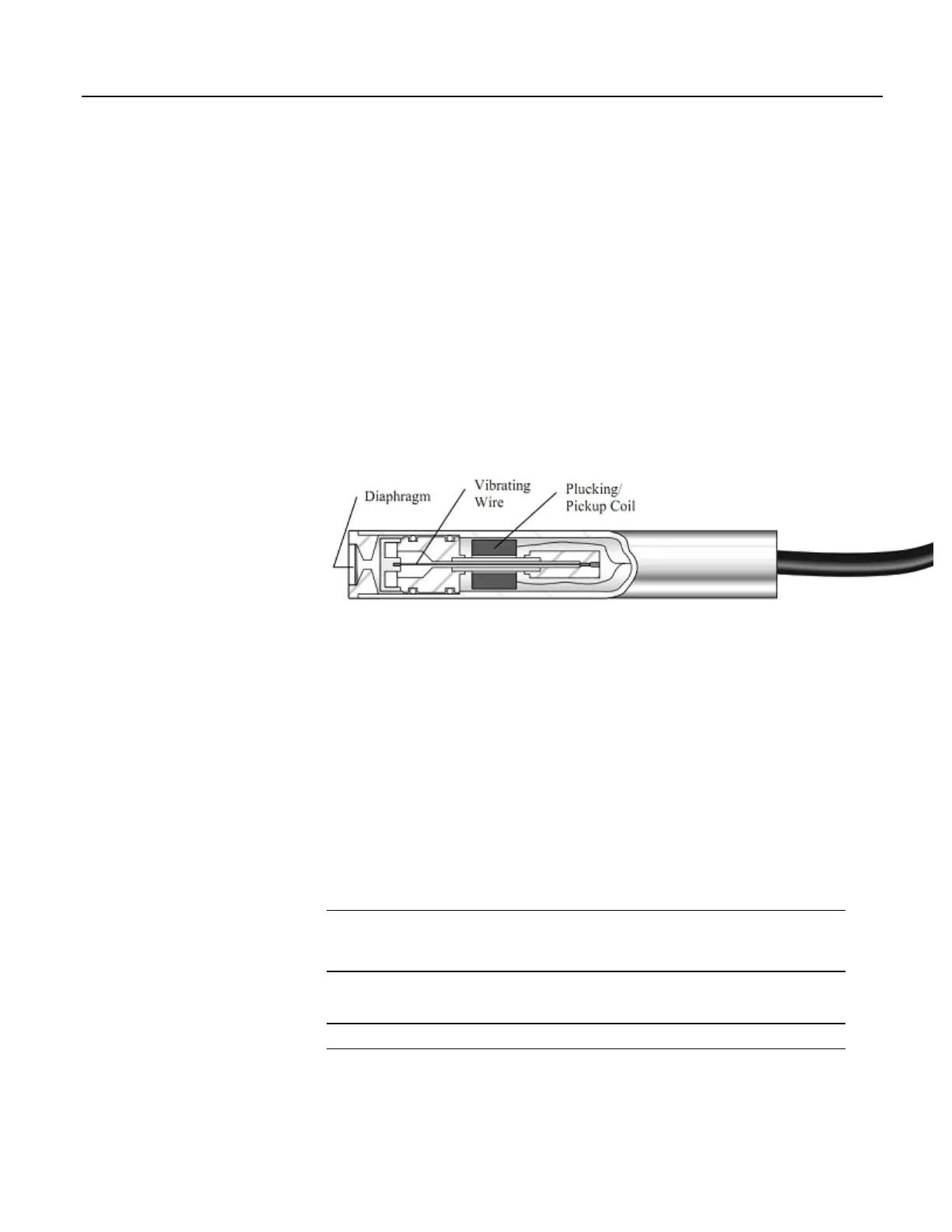

The figure Vibrating-Wire Sensor (p. 362) illustrates basic construction of a sensor.

To make a measurement, plucking and pickup coils are excited with a swept

frequency

(p. 530). The ideal behavior then is that all non-resonant frequencies

quickly decay, and the resonant frequency continues. As the resonant frequency

cuts the lines of flux in the pickup coil, the same frequency is induced on the

signal wires in the cable connecting the sensor to the CR1000 or interface.

Measuring the resonant frequency by means of period averaging is the classic

technique, but Campbell Scientific has developed static and dynamic spectral-

analysis techniques (VSPECT

(p. 532)t

m

) that produce superior noise rejection,

higher resolution, diagnostic data, and, in the case of dynamic VSPECT,

measurements up to 333.3 Hz.

A resistive-thermometer device (thermistor or RTD), which is included in most

vibrating-wire sensor housings, can be measured to compensate for temperature

errors in the measurement.

Figure 96. Vibrating-Wire Sensor

8.1.5.1 Time-Domain Measurement

Although obsolete in many applications, time-domain period-averaging vibrating-

wire measurements can be made on H L terminals. The VibratingWire()

instruction makes the measurement. Measurements can be made directly on these

terminals, but usually are made through a vibrating-wire interface that amplifies

and conditions the vibrating-wire signal and provides inputs for embedded

thermistors or RTDs. Interfaces of this type are no longer available from

Campbell Scientific.

For most applications, the advanced techniques of static and dynamic VSPECT

TM

measurements are preferred.

8.1.6 Reading Smart Sensors — Details

Related Topics:

• Reading Smart Sensors — Overview (p. 71)

• Reading Smart Sensors — Details

(p. 362)

8.1.6.1 RS-232 and TTL

Read More Serial Input / Output Instructions (p. 583) and Serial I/O (p. 245).

The CR1000 can receive and record most TTL (0 to 5 Vdc) and true RS-232 data

from devices such as smart sensors. See the table CR1000 Terminal Definitions

(p.

362

Loading...

Loading...