• The typical (and industry accepted) manufacturing error of thermocouple

wire

• The reference temperature

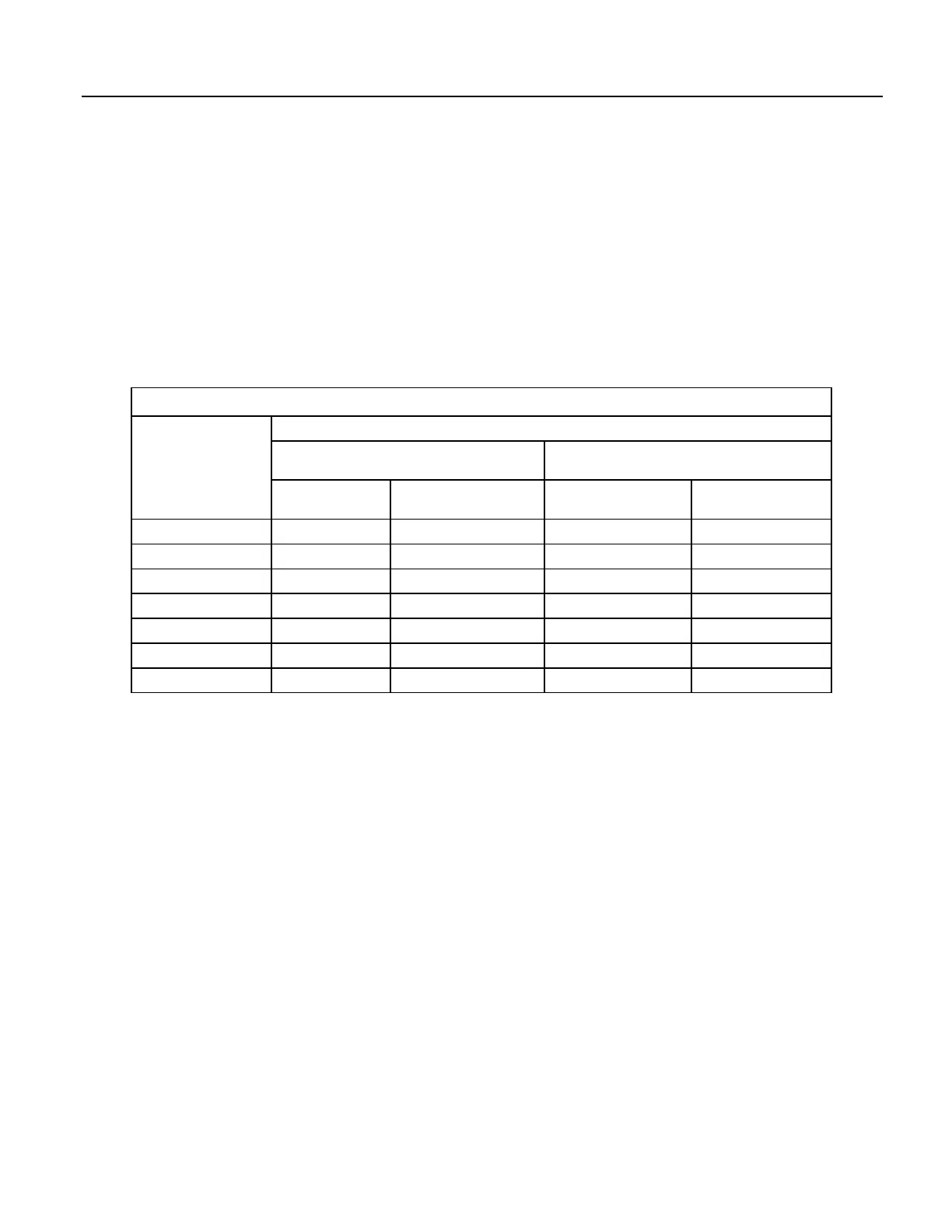

The table Thermocouple Error Examples

(p. 336) tabulates the relative magnitude of

these errors. It shows a worst case example where,

• A temperature of 45 °C is measured with a type-T thermocouple and all

errors are maximum and additive:

• Reference temperature is 25 °C, but it is indicating 25.1 °C.

• The terminal to which the thermocouple is connected is 0.05 °C cooler than

the reference thermistor (0.15 °C error).

Table 70. Thermocouple Error Examples

Source

Error: °C : % of Total Error

Single Differential

250 µs Integration

Reversing Differential

50/60 Hz Rejection Integration

ANSI TC Error

(1°C)

TC Error 1% Slope ANSI TC Error (1°C) TC Error 1% Slope

Reference Temperature 0.15° : 11.5% 0.15° : 29.9% 0.15° : 12.2% 0.15° : 34.7%

TC Output 1.0° : 76.8% 0.2° : 39.8% 1.0° : 81.1% 0.2° : 46.3%

Voltage Measurement 0.12° : 9.2% 0.12° : 23.9% 0.07° : 5.7% 0.07° : 16.2%

Noise 0.03° : 2.3% 0.03° : 6.2% 0.01° : 0.8% 0.01° : 2.3%

Reference Linearization 0.001° : 0.1% 0.001° : 0.2% 0.001° : 0.1% 0.001° : 0.25%

Output Linearization 0.001° : 0.1% 0.001° : 0.2% 0.001° : 0.1% 0.001° : 0.25%

Total Error 1.302° : 100% 0.502° : 100% 1.232° : 100% 0.432° : 100%

8.1.2.2.2 Use of External Reference Junction

An external junction in an insulated box is often used to facilitate thermocouple

connections. It can reduce the expense of thermocouple wire when measurements

are made long distances from the CR1000. Making the external junction the

reference junction, which is preferable in most applications, is accomplished by

running copper wire from the junction to the CR1000. Alternatively, the junction

box can be used to couple extension-grade thermocouple wire to the

thermocouples, with the PanelTemp() instruction used to determine the reference

junction temperature.

Extension-grade thermocouple wire has a smaller temperature range than standard

thermocouple wire, but it meets the same limits of error within that range. One

situation in which thermocouple extension wire is advantageous is when the

junction box temperature is outside the range of reference junction compensation

provided by the CR1000. This is only a factor when using type K thermocouples,

since the upper limit of the reference compensation polynomial fit range is 100 °C

and the upper limit of the extension grade wire is 200 °C. With the other types of

thermocouples, the reference compensation polynomial-fit range equals or is

greater than the extension-wire range. In any case, errors can arise if temperature

gradients exist within the junction box.

Figure Diagram of a Thermocouple Junction Box

(p. 337) illustrates a typical

336

Loading...

Loading...