3. Mode

35951

2/3

35951

Self-diagnostic

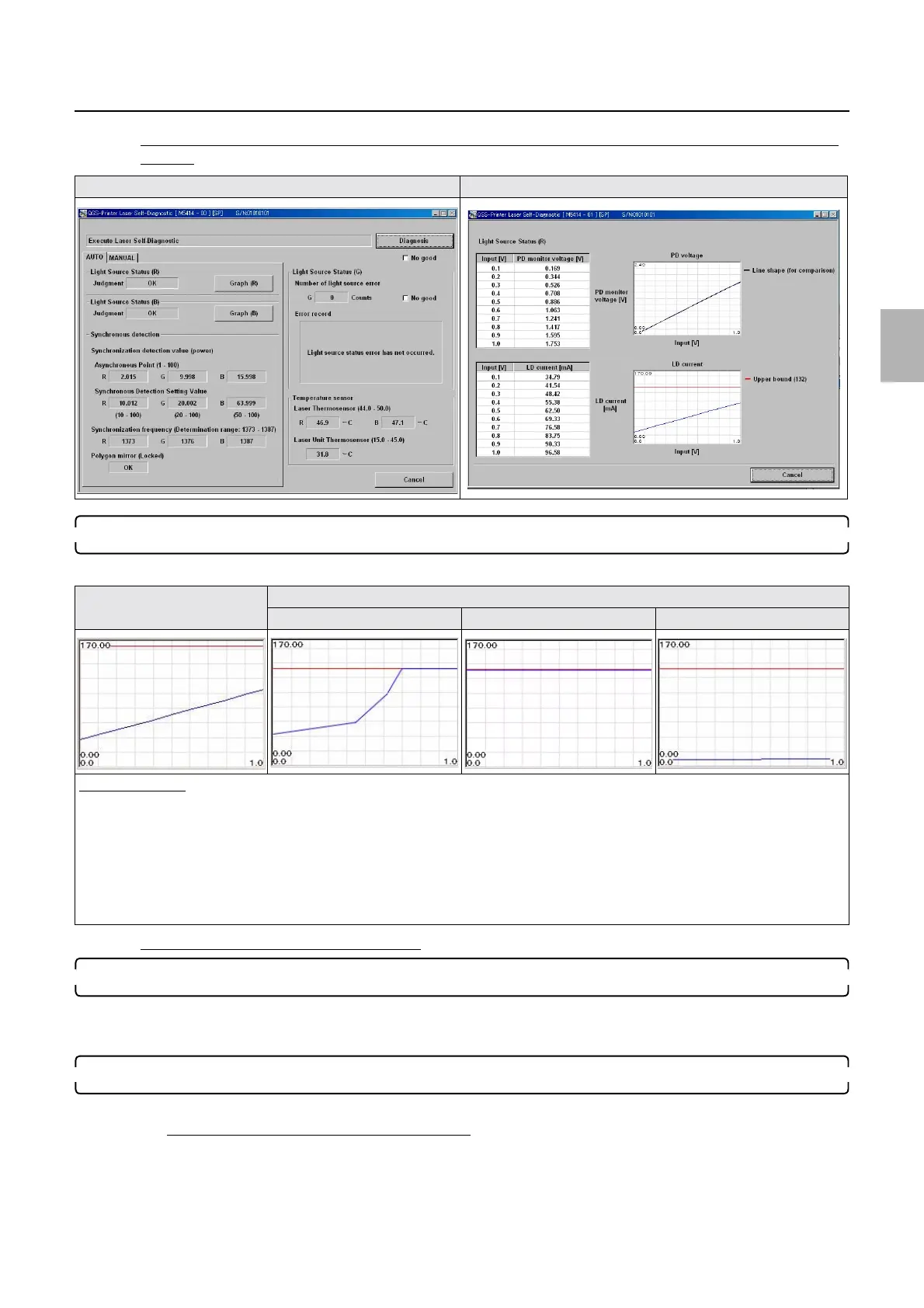

Example: If the diagnosis result is normal (FRONTIER-Printer: Ver. 3.0 or later, QSS-Printer: Ver. 5.0

or later)

4. Right Source Status (R) and Right Source Status (B) are abnormal

Confirm graph (R) and graph (B).

Diagnosis example (when problem lies in G laser)

5. Synchronous Detection Setting Value G is abnormal

• Confirm that there is no connection failure in wiring between the laser control PCB and the laser unit.

• Confirm that there is no connection failure in wiring between the laser control PCB and the G-AOM driver.

6. Perform Laser Self-Diagnostic (AUTO) again, and if it still recurs, replace the G-AOM driver.

1. Perform Laser Self-Diagnostic (AUTO) again.

Synchronous Detection Setting Value

G is abnormal

• There is a possibility of failure in the laser unit.

1. Countermeasure 1: reattach the G-AOM driver then replace the laser unit.

2. Countermeasure 2: diagnose again by Laser Self-Diagnostic (AUTO) .

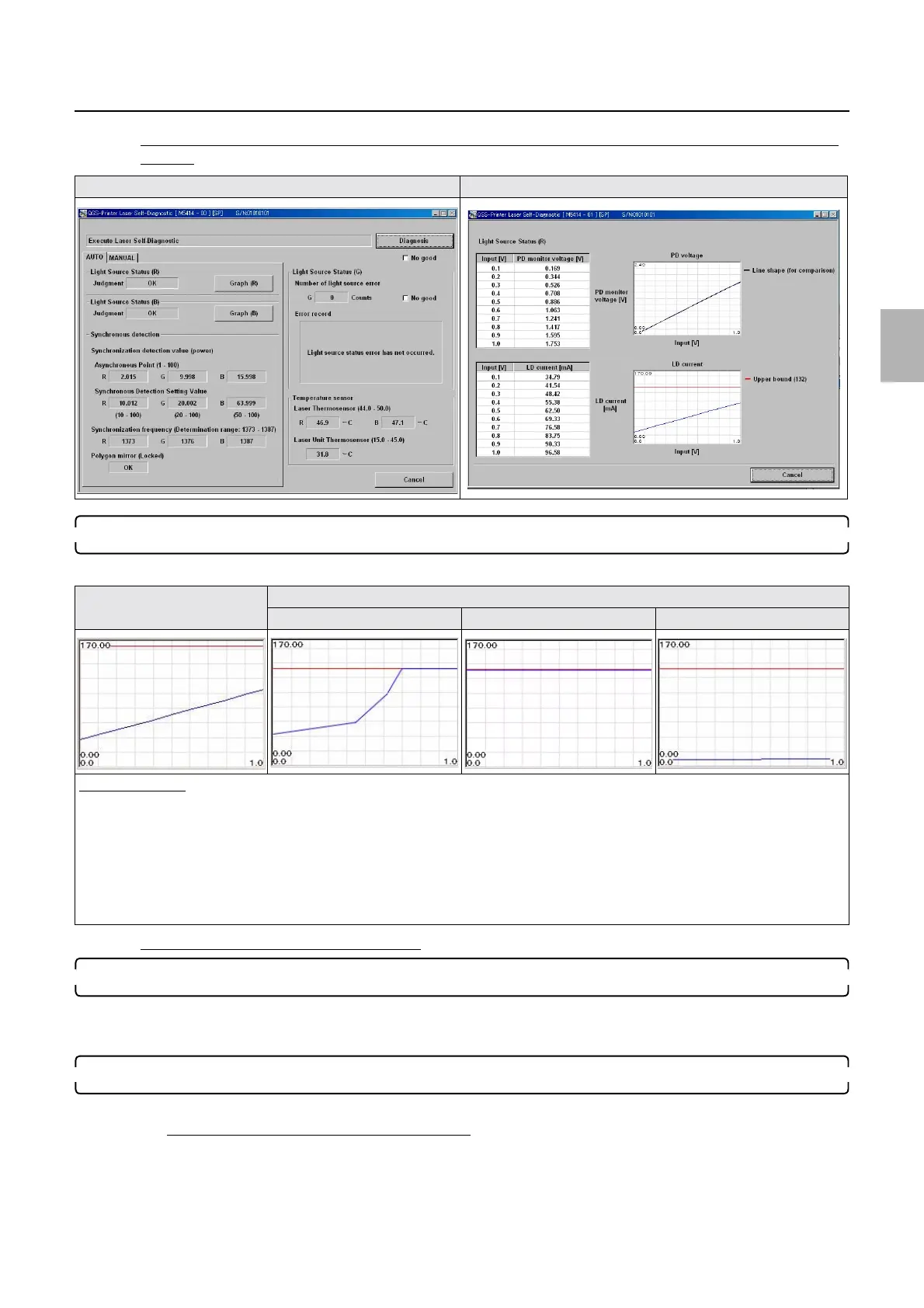

Laser Self-Diagnostic Laser Self-Diagnostic (graph (R))

LD current graph (normal) LD current graph (abnormal)

Graph (1) Graph (2) Graph (3)

Diagnosis example

• ☞Graph (1), ☞Graph (2)

If the graph of the LD current is not showing a straight line but a polygonal line that touches the upper bound or keeps touching it, it

is assumed that the laser unit LD is deteriorated.

Countermeasure: replace the laser unit.

•

☞Graph (3)

If the graph of the LD current is showing a horizontal line that lies near 0 mV level, connection failure in the laser control PCB

connector (coaxial cable (R)) or failure in the laser control PCB can be suspected.

Distributed by: minilablaser.com

Loading...

Loading...