3. Mode

36090

2/2

36090

Printer Mechanical Adjustment

!

!!

! Rewind

The paper which has been loaded is rewound.

!

!!

! Adjusting procedure

1. Select and execute Test Print via F:Functions.

NOTE

• 13 patterns of the test prints are made as shown in the list below.

• When the CVP (optional) has been installed, the print No. and the revolution pulse count are printed on the back print.

2. Banding appears around 17 mm or 26 mm from the rear end on the test print. Check the table below

and enter the correction pattern No. as the correction value.

3. Carry out the procedure 1 and 2 for each paper magazine type.

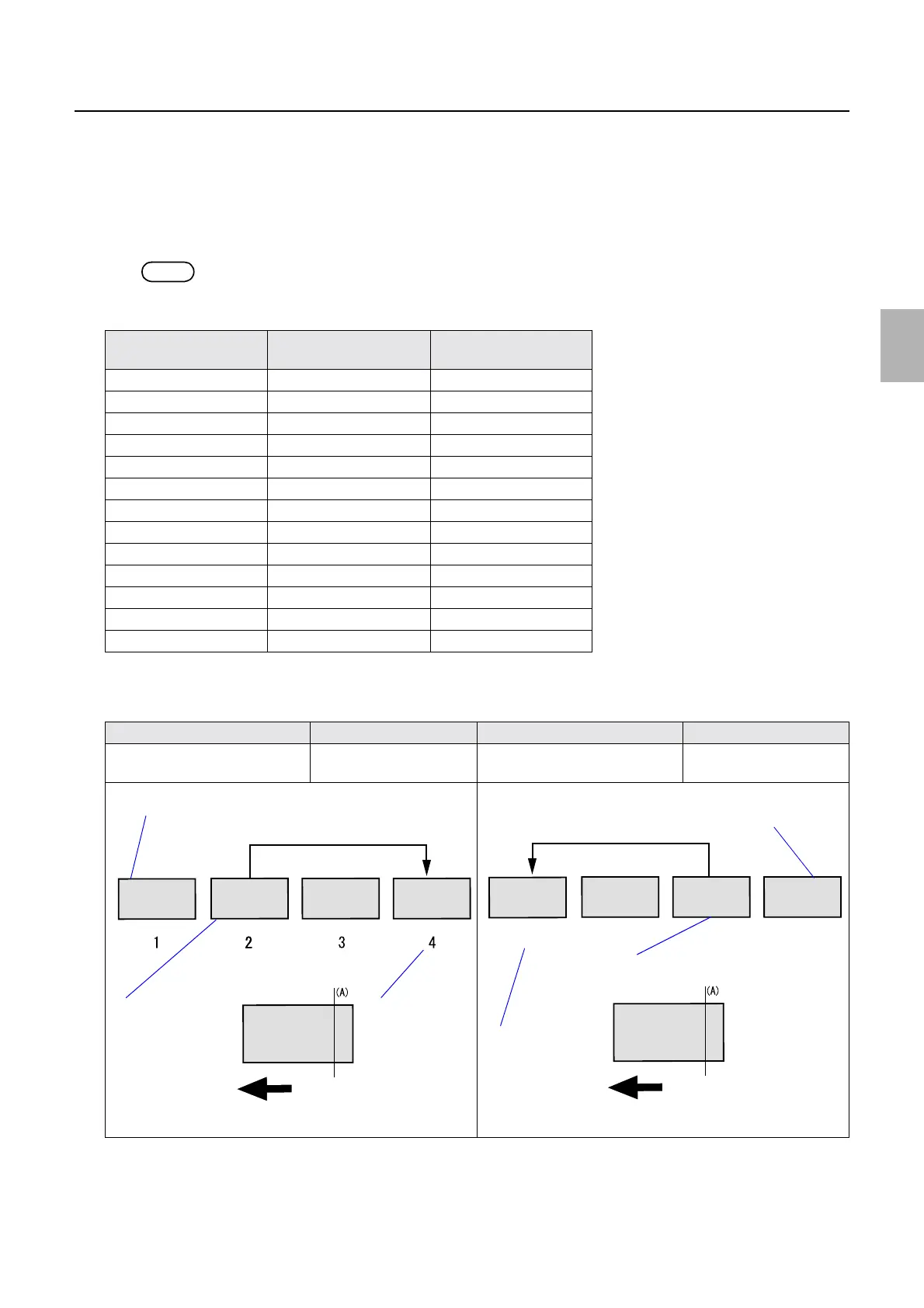

Print No. Revolution pulse count

(pps)

Test print advance

length (mm)

1 1733 152

2 1600 153

3 1545 154

4 1502 155

5 1466 156

6 1434 157

7 1405 158

8 1378 159

9 1353 160

10 1329 161

11 1307 162

12 1285 163

13 1265 164

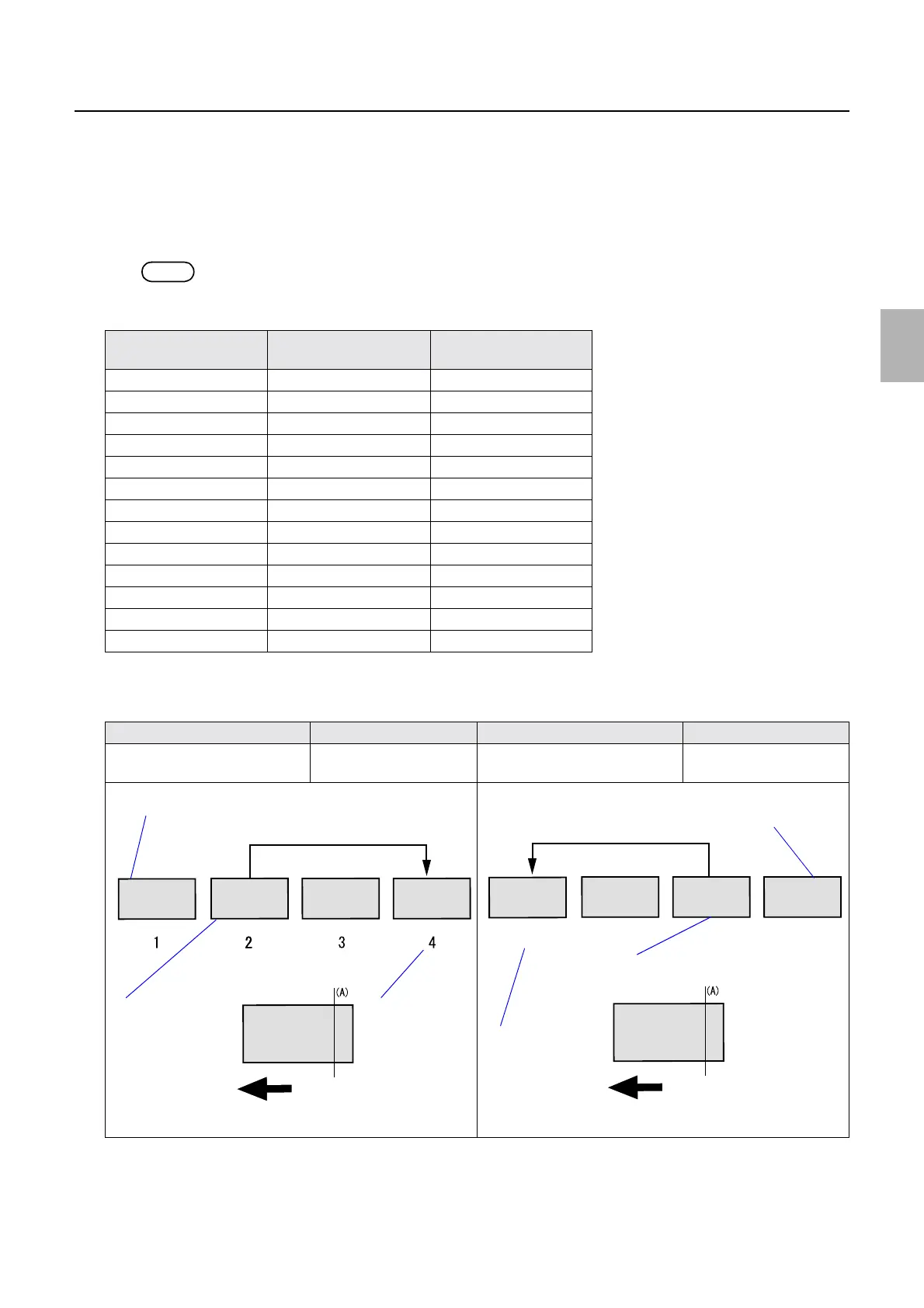

Banding position Correction Banding position Correction

Around 26 mm from the paper rear

edge

+2 Around 17 mm from the paper rear

edge

−2

Example: Around 26 mm at the rear end Example: Around 17 mm at the rear end

Banding (26 mm at the rear end)

Paper advance direction

+2

Print No.

Test print with no

banding

11

10

13

12

Banding (17 mm at the rear end)

Paper advance direction

−2

Print No.

Test print with no

banding

Distributed by: minilablaser.com

Loading...

Loading...