2/3

2. Replacement and adjustment of parts

25910

25910

Exposure advance unit

!

!!

! Banding shooting

Print condition Banding position Status Corrective action Refer to

All Around 0 to 11 mm from the

paper leading edge

The bumper rubber for the laser control

box is detached.

Attach the bumper

rubber.

-

The exposure advance unit vibrates

during printing operation.

Attach the reinforcement

angle bracket to the

exposure advance unit.

☞25810

At the area 33.5 mm from the

paper leading end

The pressure of the exit side pressure

roller in the exposure advance unit is

uneven.

Adjust the zigzagging of

the exposure advance

unit.

☞25830

• The advance belt is removed from

the pressure guide.

• The advance belt of the pressure

guide is damaged.

Check the condition of

the advance belt of the

pressure guide.

☞20110

Around 17 mm from the

paper rear edge

The inlet side pressure roller release

amount of the exposure advance unit is

too small.

Perform the paper

pressure operation

correction.

☞36090

Around 26 mm from the

paper rear edge

The inlet side pressure roller release

amount of the exposure advance unit is

too big.

Around 24 to 27 mm from

the paper rear edge

The pressure of the inlet side pressure

roller in the exposure advance unit is

uneven.

Adjust the zigzagging of

the exposure advance

unit.

☞25830

Banding is generated over

the print in a cycle (210 mm).

The belt tension of exposure advance

motor 2 belt is maladjusted.

Check exposure advance

motor 2 belt.

☞20110

Banding is generated over

the print in a cycle (55 mm).

Whole of the print (no

repetition)

The screws of the exposure advance unit

are loose.

Tighten the screws of the

exposure advance unit.

☞25810

External vibration is applied to the

system.

--

All jack bolts are not effective. Check the level of the

printer.

-

The strength of the floor is insufficient. - -

The banding cannot

be found on the first

and the last prints in

the Continuous

Print. The banding

cannot be found on

the print when only

one print is made.

Around 55 mm from the

paper rear edge

The bumper rubber for the laser control

box is detached.

Attach the bumper

rubber.

-

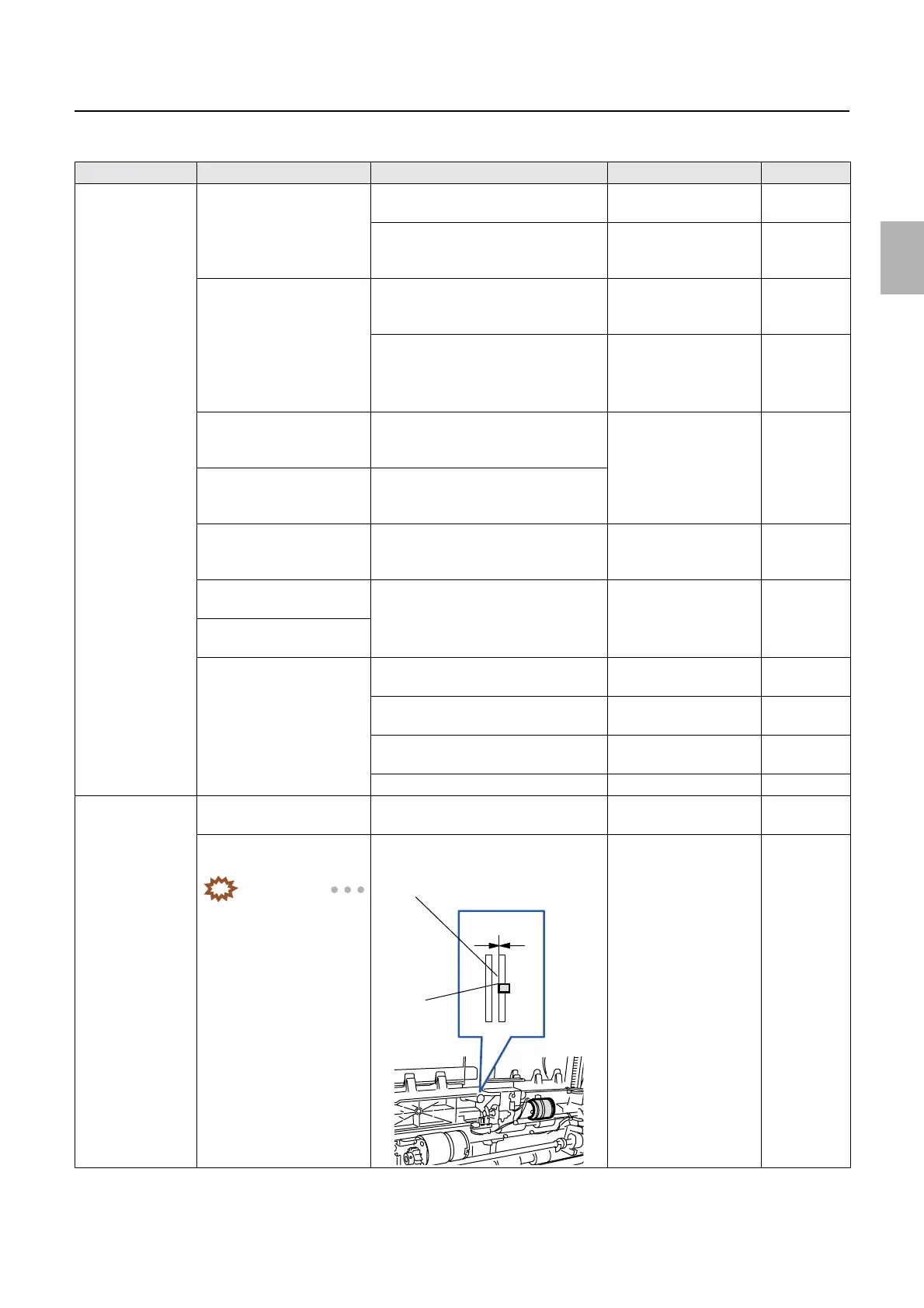

around 45 to 48 mm from the

paper rear edge

IMPORTANT

• This banding occurs

when a paper is being

exposed while the

next paper to expose

is advanced from the

paper supply unit to

the exposure advance

unit.

The pressure pin of the paper supply unit

comes out of the guide.

Adjust the position of the

pressure pin of the paper

supply unit.

☞25640

0.0 mm

Pressure

pin

Guide

Distributed by: minilablaser.com

Loading...

Loading...