ID 442426.04 90WE KEEP THINGS MOVING

Connection

7

Manual SD6

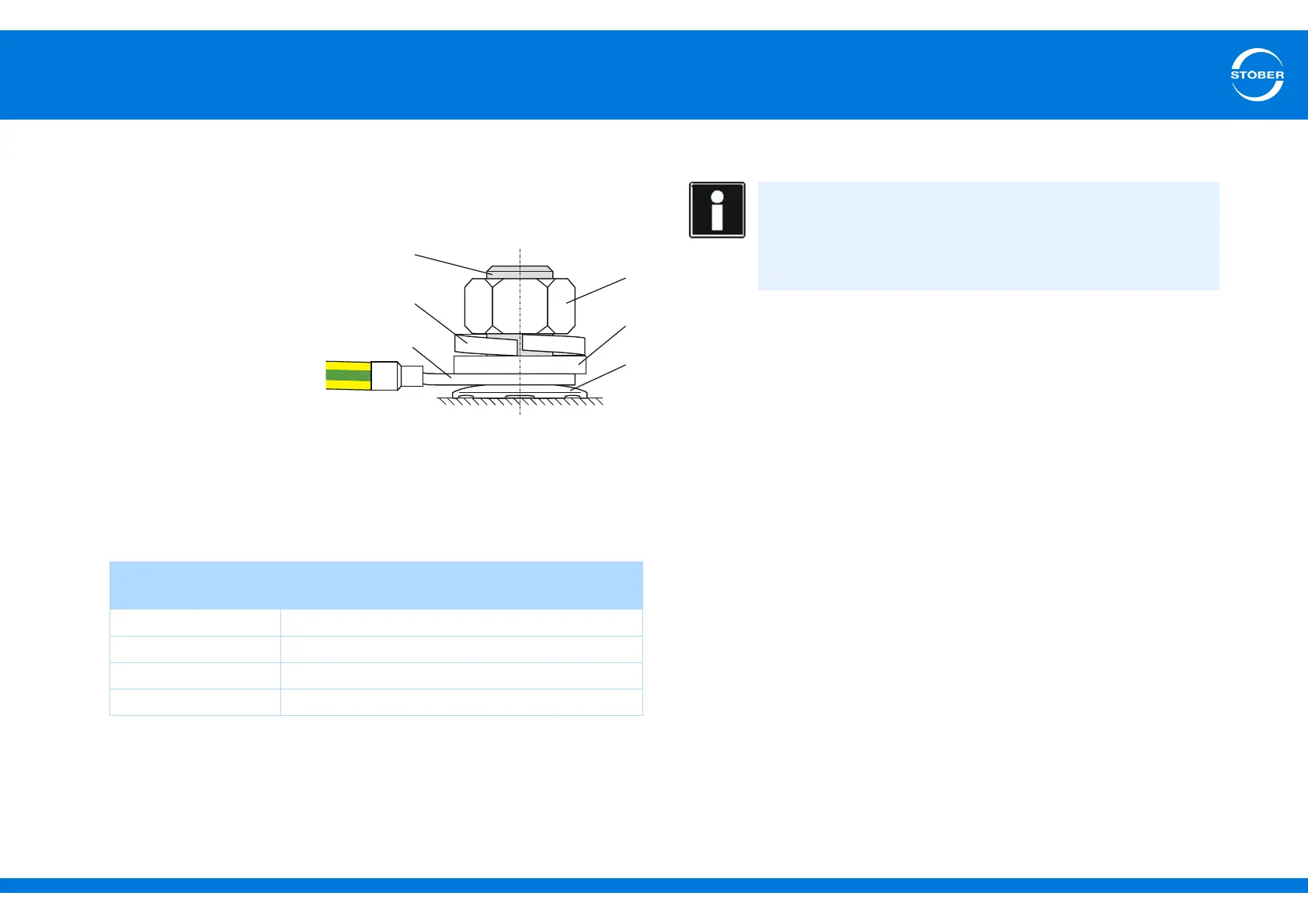

7.2.2.3 Housing ground

Note the following information on the connection of the protective earth to

ground the housing correctly:

• Note the assembly sequence:

• 1 M6 earth bolt

• 2 Contact disk

• 3 Cable socket

•4 Washer

• 5 Return spring

(optional)

•6 Nut

Contact disk, washer,

return spring and nuts are supplied with the drive controller.

• Tightening torque: 4 Nm

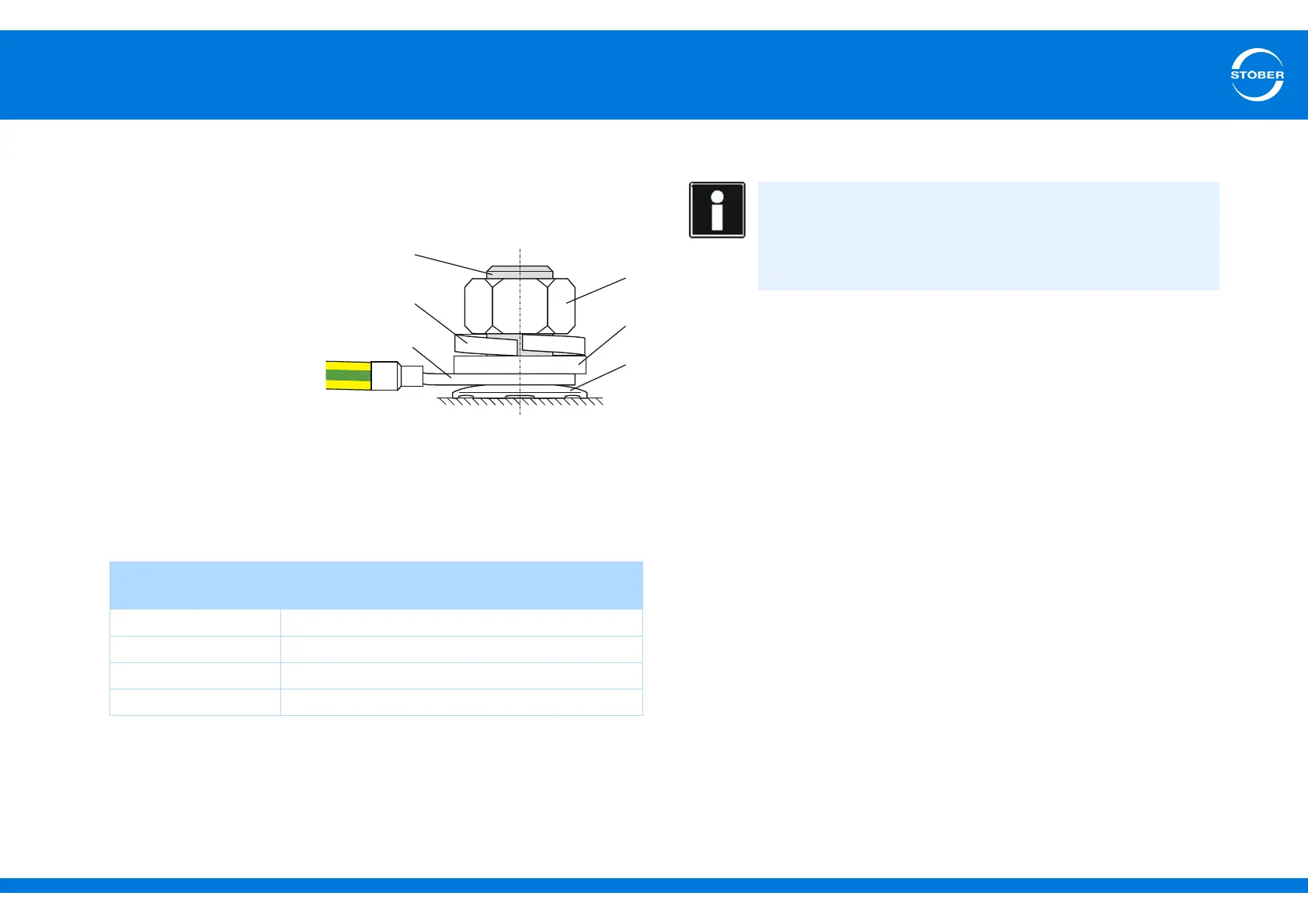

• Stray currents > 10 mA can arise in normal operation. To fulfill DIN EN

61800-5-1 and EN 60204-1, connect the earth bolts with a copper

conductor according to the following table:

7.2.3 EMC connection

• Lay the power line, motor cable and signal lines separately from each other,

e.g. in separate cable channels.

• Only use shielded, low-capacitance cables as motor cables.

• If the brake line is carried in the motor cable, it must be separately shielded.

• Connect the shield of the motor cable with large contact areas and in the

immediate vicinity of the drive controller. Use the EM6 EMC shroud to do

this.

• Shield the cable for connection to a braking resistor if it exceeds a length

of 30 cm. In this case, connect the shield with large contact areas and in

the immediate vicinity of the drive controller.

• For motors with terminal boxes, connect the shield to the terminal box with

large contact areas. For example, use EMC cable screw connections.

• Connect the shield of the control lines on one side with the reference

ground of the source, e.g. the PLC or CNC.

Cross-section A

Feeder

Minimum cross-section A

min

Earth conductor at earth bolts

A ≤ 2.5 mm

2

2.5 mm

2

2.5 < A ≤ 16 mm

2

A

16 – 35 mm

2

≥16 mm

2

> 35 mm

2

A/2

Information

This section provides general information on EMC-compliant

installation. This involves recommendations. Depending on the

application, ambient conditions as well as the legal requirements,

measures beyond these recommendations may be required.

Loading...

Loading...