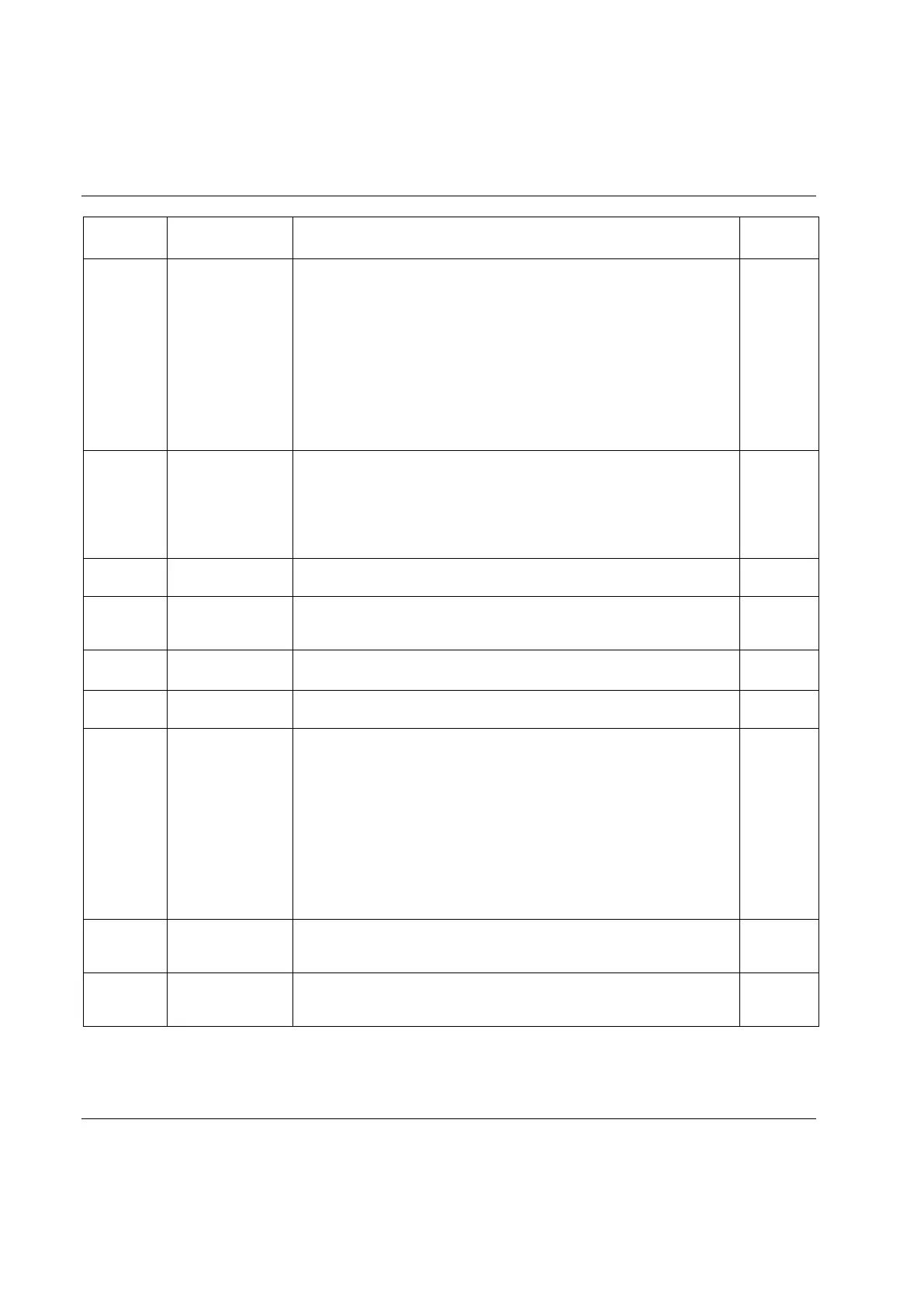

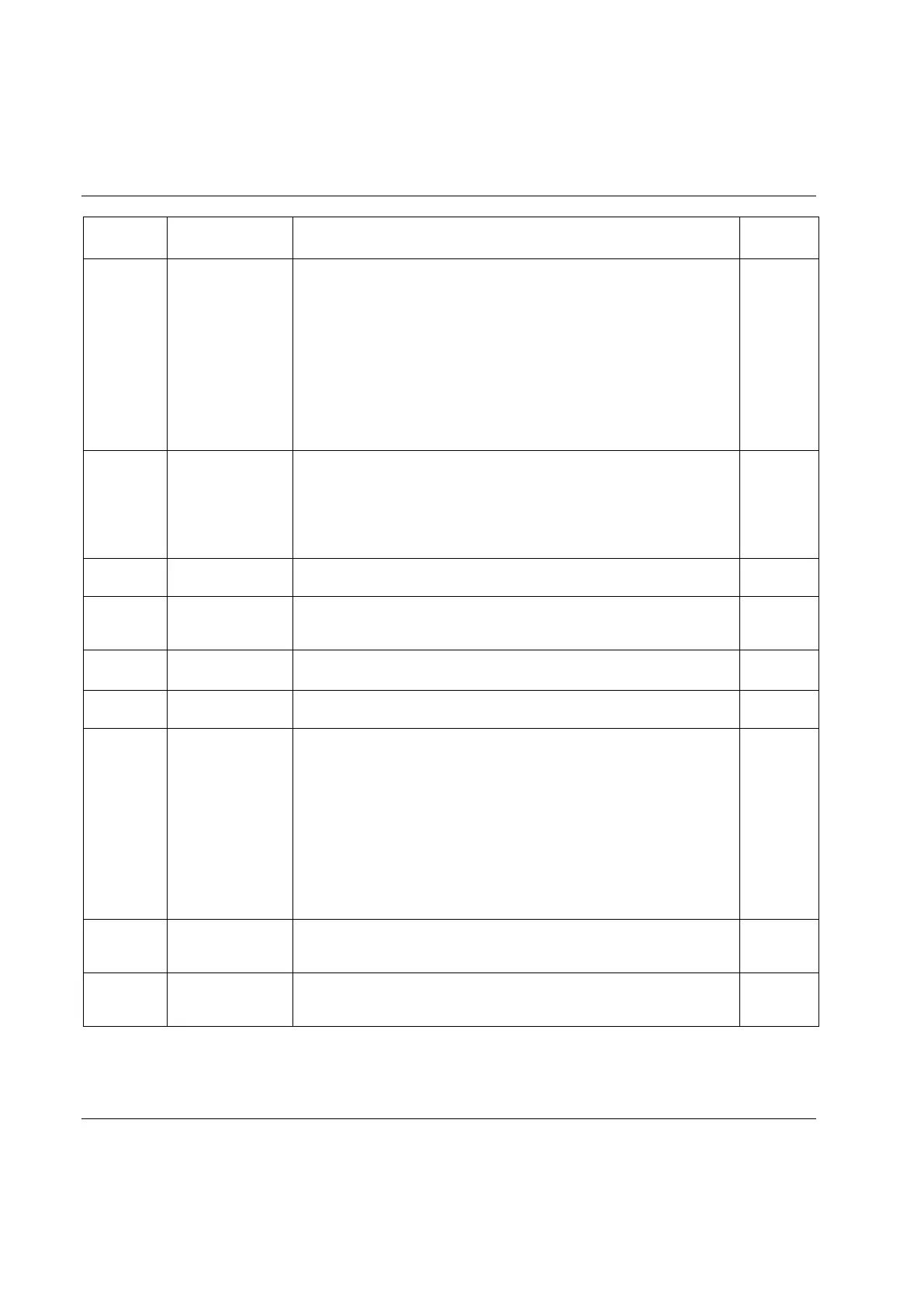

Parameter list

342 (428) 9836 3123 01

One stage: tightening is performed in one stage. Control is done from P110

Cycle start until P113 Final target is reached.

Two stage: tightening is performed in two stages. Control is done from P110

Cycle start until P111 First target. The tool stops and then accelerates to a

lower speed and controls until P113 Final target is reached.

Quick step: quick step is a variant of a two stage tightening. The difference is

that the tool speed changes directly from the higher speed to the lower speed

without stopping.

Ergo ramp: This is a two stage strategy with a constant increase in torque

during the second stage of the tightening. Gives the operator constant reaction

torque in the tool regardless of joint hardness.

This parameter is optional. If chosen, there are two alternatives.

From start: The rundown phase starts when the tool trigger is pressed and

continues until the torque value reaches P116 Rundown complete.

From cycle start: The rundown phase starts when the torque level exceeds the

P110 Cycle start torque level and continues until P116 Rundown complete is

reached.

This parameter enables the zoom step function. Zoom step strategy combines

quick tightening with high precision and low scatter.

This parameter is only used if Click wrench is chosen as P100 Control

strategy. It is used to connect the click wrench strategy to any one of four

defined digital input.

Will generate a Trace from Tool start or P110 Cycle start.

For STwrench, only P110 Cycle start is available.

Decides if monitoring of end time (cycle complete) will start from P110

Cycle start or P116 Rundown complete.

Defines the starting level for a tightening cycle.

IF P100

Control

strategy is

set to DS

con or DS

con/tq mon:

0.1 * T102

ELSE:

0.05 * T102

Tool max

torque

Defines the level at which the changeover takes place between the first and

second stage in a two stage tightening, quick step or ergo ramp.

0.25 * T102

Tool max

torque

Defines the lower torque limit for OK tightening.

0.3 * T102

Tool max

torque

Loading...

Loading...