Parameter list

370 (428) 9836 3123 01

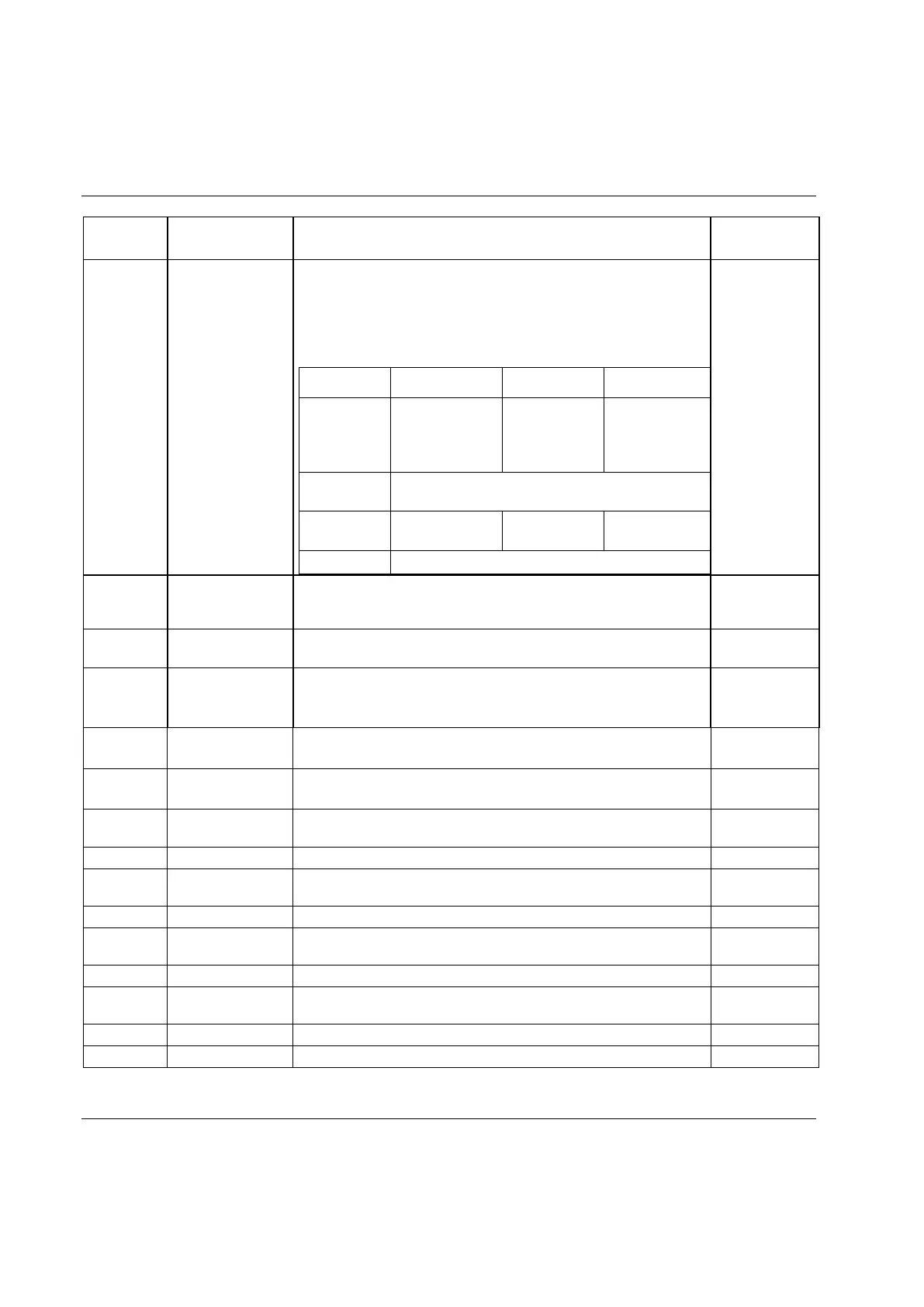

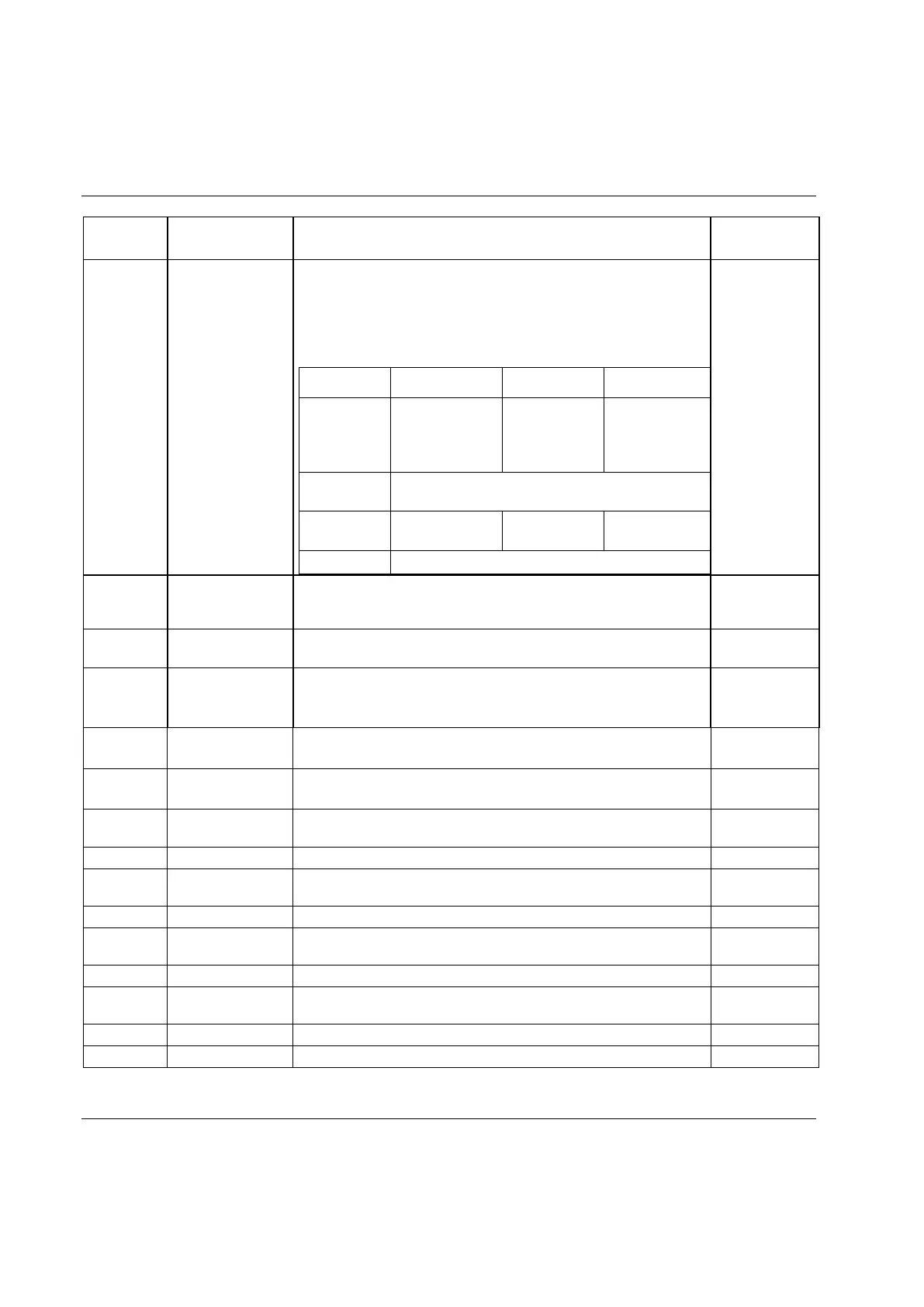

Selection of tool light control sources. Defines which protocol the tool

lights should follow:

Available options: PF-controlled:1, PF-controlled:2, PF-controlled:3,

Light off.

The table below shows the functionality of the tool LED’s for each

option.

LOW. Torque

and/or angle

values under

specified limits.

HIGH. Torque

and/or angle

values over

specified limits.

OK. Torque and

angle values

within specified

limits.

Event code to be

acknowledged

Tool LED’s functionality disabled.

On/Off. Defines whether the tool LED’s should light for a specified

period of time (on) or continuously (off) after a tightening. Default is

off.

Select time for tool light LED, can be set between 0 and 300 seconds.

Only valid if C261 Use on time is on.

Configures ST tool to show selected Pset (Pset 1-8) on the tool LED's.

Available options: Off, Pset indication

Applicable only if an ST tool is connected.

Tool will turn off automatically if inactive for this period of time.

Unit: Minutes. Min value: 1. Max value: 120.

Tool radio start condition

Alternatives: Off, Connected, Start request

After this timeout the tool is considered offline.

Unit: Milliseconds. Min value: 1000. Max value: 60000.

Max sender power on the IRC module. Only IRC-B.

Whether or not a torque and angle trace should be produced for every

tightening. Only IRC-B.

Sets if the parameter T270 Power save timeout is active or not.

This setting determines if a tool lock request shall be delayed until the

current tightening/loosening/positioning is completed.

Expected primary tool connection. Cable or IRC.

When selected, IRC pairing starts if tool is in pairing mode and tool

connection is IRC-B.

Port for STB tool IP connection.

Serial port where IRC-B device is connected. Serial 2 or internal.

Loading...

Loading...