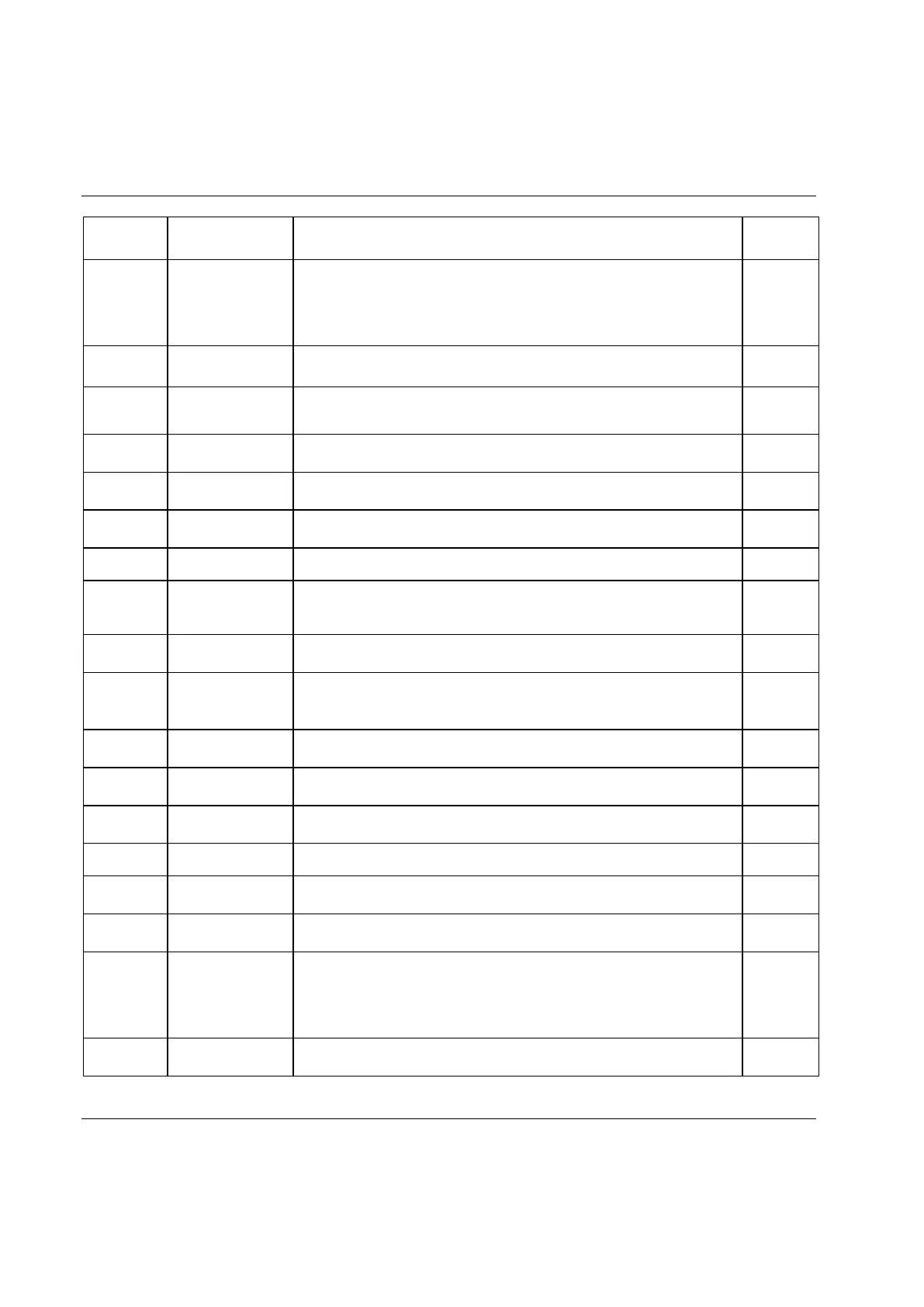

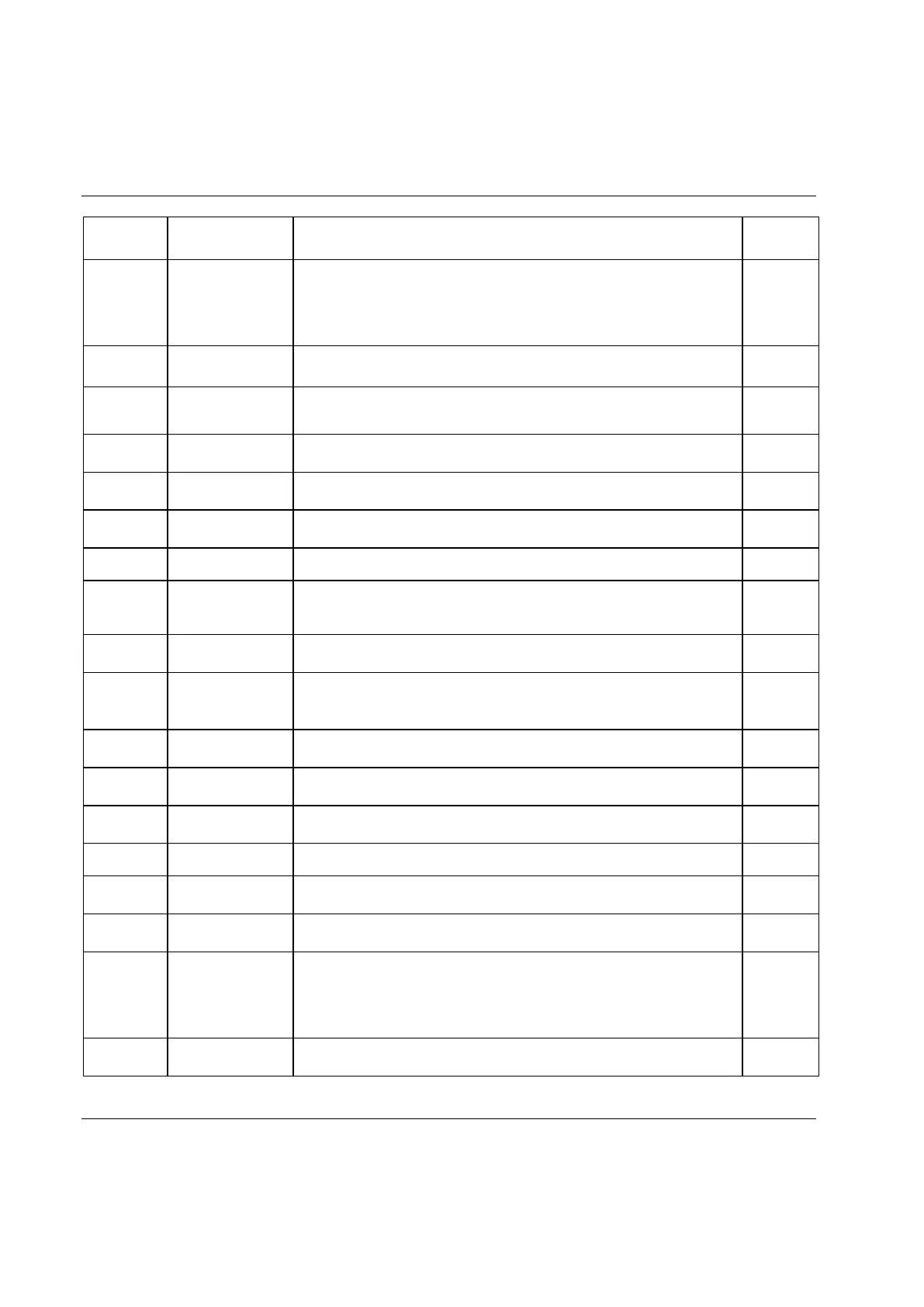

Parameter list

372 (428) 9836 3123 01

This parameter sets the T400 Calibration value and the T401 Calibration date in

the tool memory, and performs a shunt calibration. The shunt calibration is

useful for determining if the shunt calibration value received at a previous

shunt calibration tends to drift away. The shunt calibration is also performed

before each new tightening, and the same checks and boundaries apply.

Shows the normalization value for the tool.

Valid scope: 100 to 9999.

0 = No alarm is active, 1 = activating of parameter T405 Calibration alarm

date. (Unix format no of seconds from 1970-01-01).

This parameter makes it possible to change date for next calibration alarm.

Set calibration

alarm date

Not applicable in the PF Graph HMI.

Total number of tightenings performed by the tool during its entire lifetime.

Enable/disable (on/off) tool service indicator alarm function.

Number of

tightenings since

service

Number of performed tightenings since latest tool service.

Number of tightenings between tool services. This parameter serves as service

indicator alarm limit. Value between 1 and 250 (x 10 000).

Shows the date of when the latest service was performed. Automatically

updated when Service counter reset is performed.

Possible to set manually to any date.

Sets T412 Number of tightenings since service to zero, sets T414 Latest service

date to current date and sets T411 Service indicator to off.

Enables/disables lock on alarm. Tool will be locked while service indicator

alarm or while wear indicator alarm is activated.

Shows a user specified message-string of maximum 35 characters plus a null-

termination. The message shall be stored in the tool memory.

Defines if a tool with an Open end head should be used.

Shows if the Open end has to use an inverted motor rotation.

Open end tightening

direction

Defines if Open end CW (clockwise) or CCW (counter clockwise) is to be

used.

The Open end tune command sets the reference position of the Open end

head, and measures the gear ratio and gear play. The tool rotates slowly in the

reverse direction until its true open position at the mechanical stop in the

Open end head is reached. Open end tuning measures the total T103 Gear ratio

and writes the new value to the tool memory.

Max torque

positioning limit

Defines the max value for P171 Limit

Loading...

Loading...