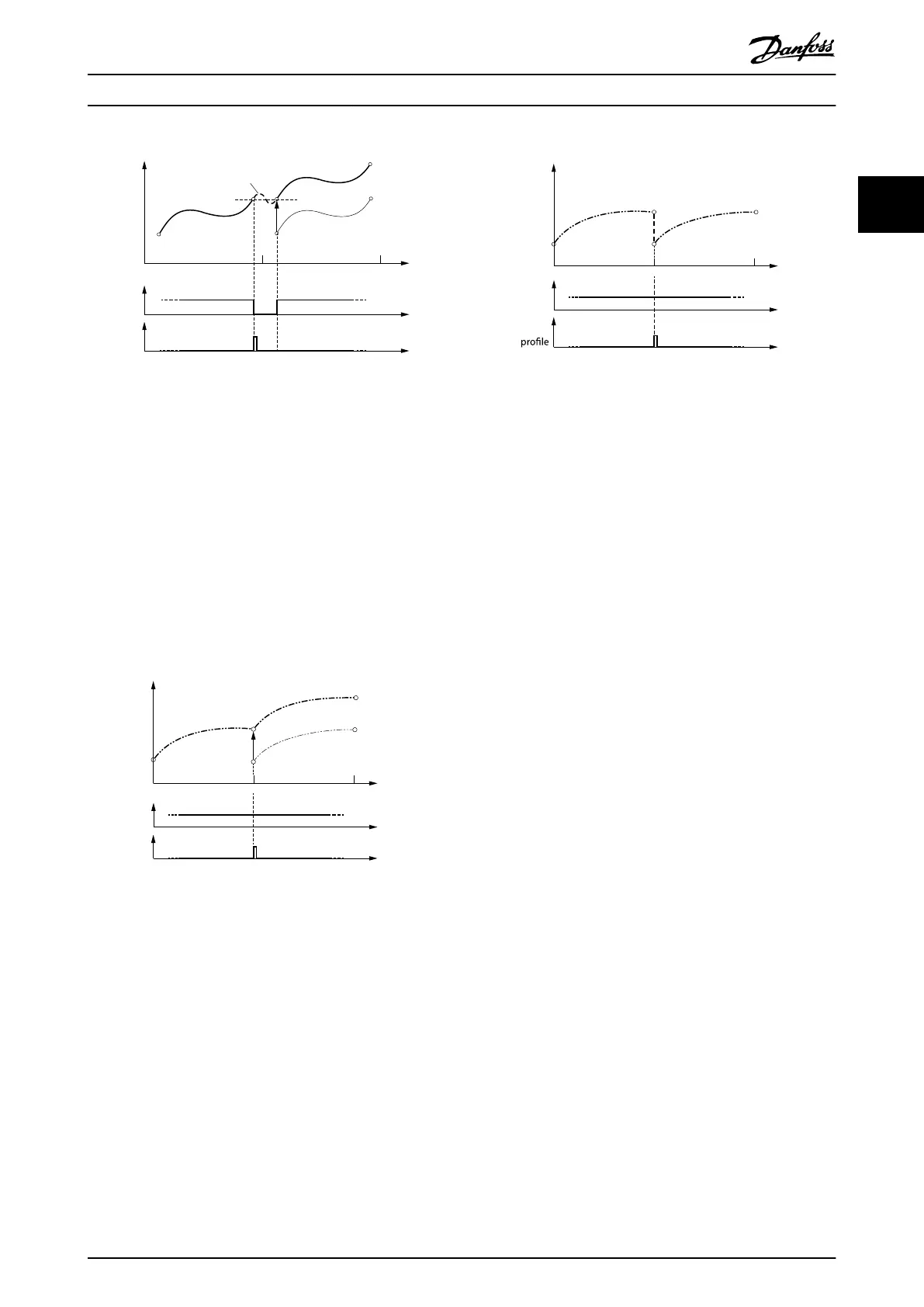

InSync

End of

prole

Rotor angle of axis

0 1

Guide value

cycle

2

Slave relative

Cyclic

Blending

130BF193.10

Slave

relative

Illustration 2.46 CAM 2: Partial CAM - Cyclic, Slave relative:

Blending Segment is an Automatically Calculated P5.

The CAM is adjusted in a way that the 1

st

rotor angle value

matches the rotor angle of the last node.

A special case in Illustration 2.46 is when the velocity of the

last point and the velocity of the 1

st

point are both 0. Then

the P5 is actually a P0.

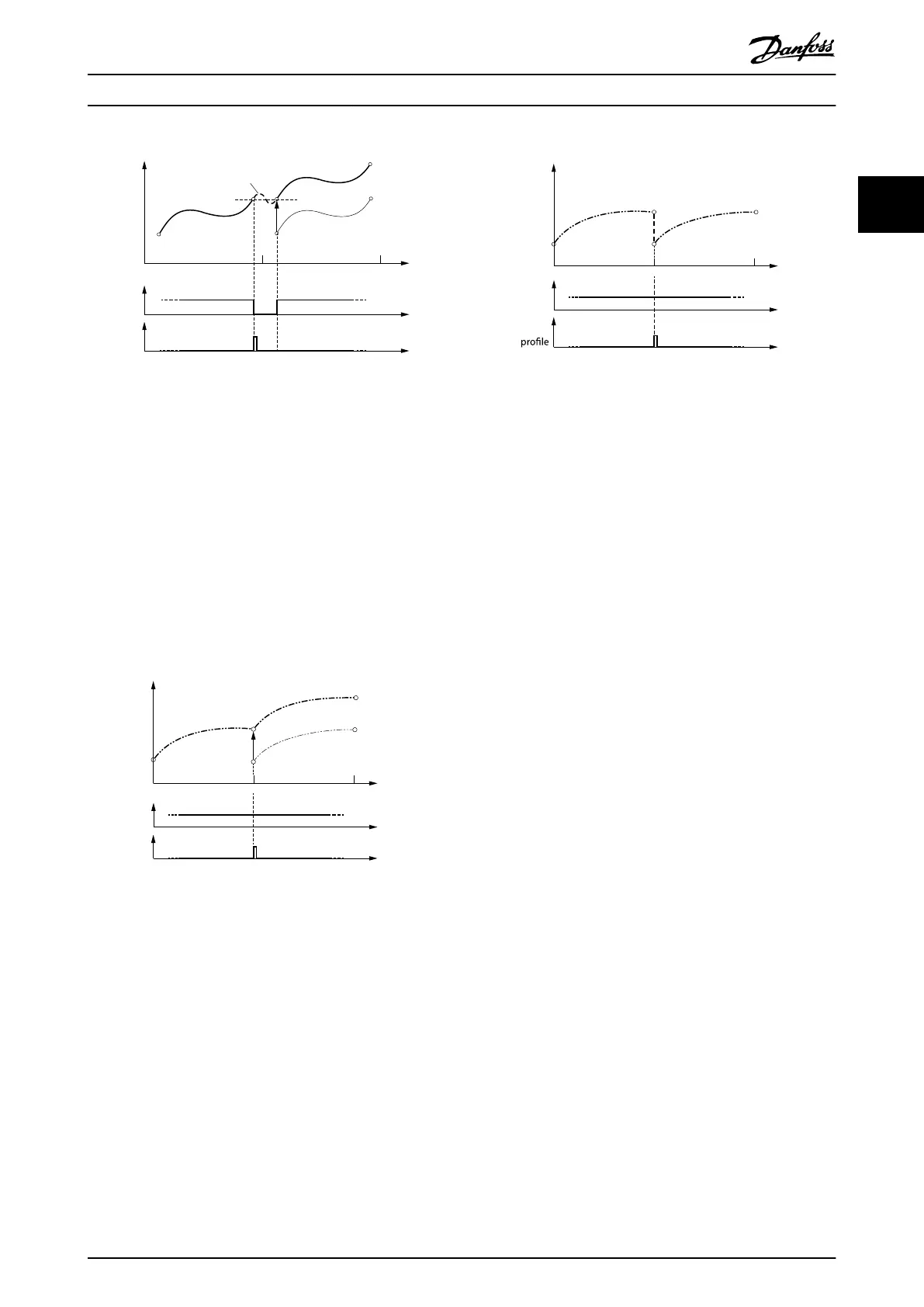

For smooth movements with cyclic use of fully dened

CAM proles, the 1

st

and the last data point of the proles

must match each other. “Matching” means having the

same velocity value and, depending on the conguration,

also the slave position value (see Illustration 2.47 and

Illustration 2.48).

Rotor angle of axis

0 1

Guide value

cycle

2

Slave relative

Cyclic

Slave

relative

InSync

End of

prole

Jump in velocity!

130BF194.10

Illustration 2.47 Cyclic, Full CAM Prole Dened Over the

Whole Guide Value Cycle.

The velocity of the 1

st

and the last node are not equal. During

execution, a jump may occur.

Rotor angle of axis

0 1

Guide value

cycle

2

Slave absolute

Cyclic

InSync

End of

Jump in position

and velocity!

130BF195.10

Illustration 2.48 Cyclic, Full CAM Prole.

The velocity and the position of 1

st

and last nodes do not

match.

Switching between CAM proles

Depending on the CAM conguration options Master

absolute/relative and Slave absolute/relative, there are

several methods to transition from 1 running CAM prole

to the next. All the possibilities are described in the

illustrations in this section. The examples all show the

starting point based on the time of the CAM activation

request, or when CAM ack (bit 12) is set by the axis (see

chapter 2.4.5.1 Activating a CAM prole).

All illustrations in the following sub-chapters show the

transition from currently running CAM 2 (see

Illustration 2.41) to a newly activated CAM 1 (see

Illustration 2.40) or CAM 3 (see Illustration 2.42). The CAM

itself is always the same, but the illustrations show the

behavior with dierent congurations and settings.

The following conventions are used for transitions between

proles:

•

The blending distance has no inuence on the

position of the CAM (for example, regarding the

automatically calculated relative oset).

•

If a CAM prole is aborted (Change CAM

imm = 1), the current slave position is considered

as end slave position.

•

When activating a non-cyclic CAM prole with

Use blend distance = 0, the processing takes place

in the same master cycle (as the CAM activation

request) or in the next one (depending on the

end point of the currently running CAM prole

and the start point of the new CAM prole). In

both cases, the prole is processed as 1 complete

cycle (starting with the next upcoming start

node).

•

When activating a non-cyclic CAM prole with

Use blend distance = 1, the processing of it (at

least the start point) takes place in the same

master cycle (as the CAM activation request),

otherwise a CAM error is issued.

Servo Drive Operation Programming Guide

MG36D102 Danfoss A/S © 01/2017 All rights reserved. 45

2 2

Loading...

Loading...