5. Operation sequence

56100

2/4

56100

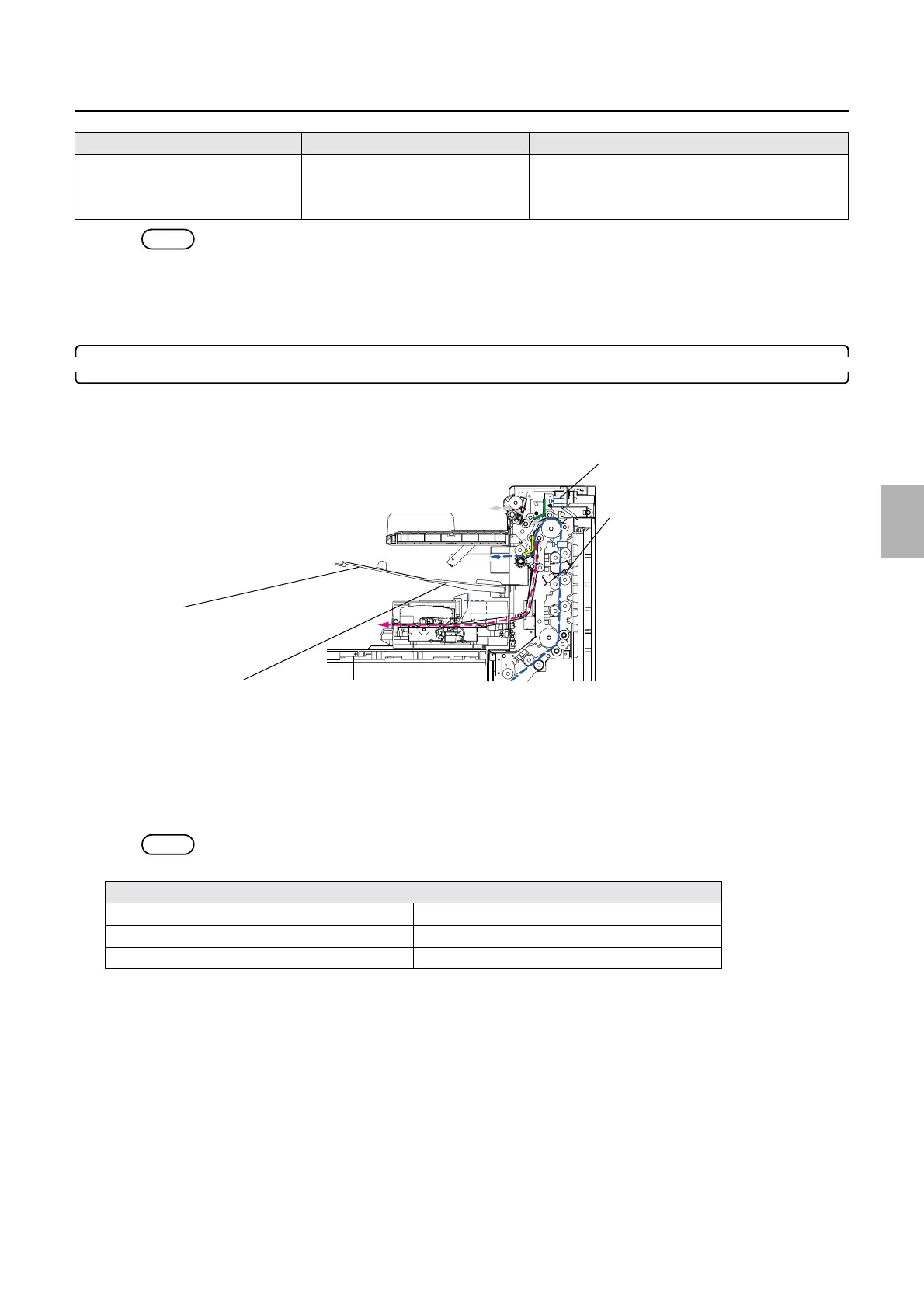

Processor paper advance operation

NOTE

• The printer examines print size to determine whether prints should be sent to the print conveyor unit or the print

receiving tray (large)/long length print tray, and then issues appropriate instructions to the processor.

!

!!

! Paper sent to the print receiving tray (large)/long length print tray:

1. The paper leading edge passes through the dryer lane select sensor.

• If the dryer lane select sensor fails to detect paper sent to the print receiving tray (large)/long length print tray within a

specified amount of time, the message

☞No. 05535-00000: Paper has jammed in the processor section. is shown

onscreen.

• The leading edge of the paper being sent to the print receiving tray (large)/long length print tray passes through the dryer

lane select sensor, activating the Dryer selection solenoid 1 and causing the select guide to move into the print receiving

tray (large) position after a specified amount of time elapses.

• The trailing edge of the paper being sent to the print receiving tray (large)/long length print tray passes through the dryer

lane select sensor, activating the dryer lane select solenoid and causing the select guide to move into the print conveyor

position after a specified amount of time elapses.

NOTE

• Paper other than standard prints also sent to the print receiving tray (large)

• Between 82.5 and 305 mm

• Between 152.1 and 305 mm

• Between 27.1 and 305 mm

• Between 305.1 and 457.2 mm

• Between 82.5 and 305 mm

• Between 457.3 and 914 mm

☞Paper sent to the print receiving tray (large)/long

length print tray:

Types of paper sent to the print receiving tray (large)

Leading-edge feed paper Trailing-edge feed paper

Fogged paper Splice

Control strips

Paper width Advance length Paper advance procedure references

Print receiving tray (large)

Dryer lane select sensor: SE45

Long Length Print Tray

Dryer selection solenoid 1

G085227

Distributed by: minilablaser.com

Loading...

Loading...