SV-MAG-236 Remote Magnetometer Installation and Configuration

SkyView HDX System Installation Manual - Revision E 8-1

8 SV-MAG-236 Remote Magnetometer Installation

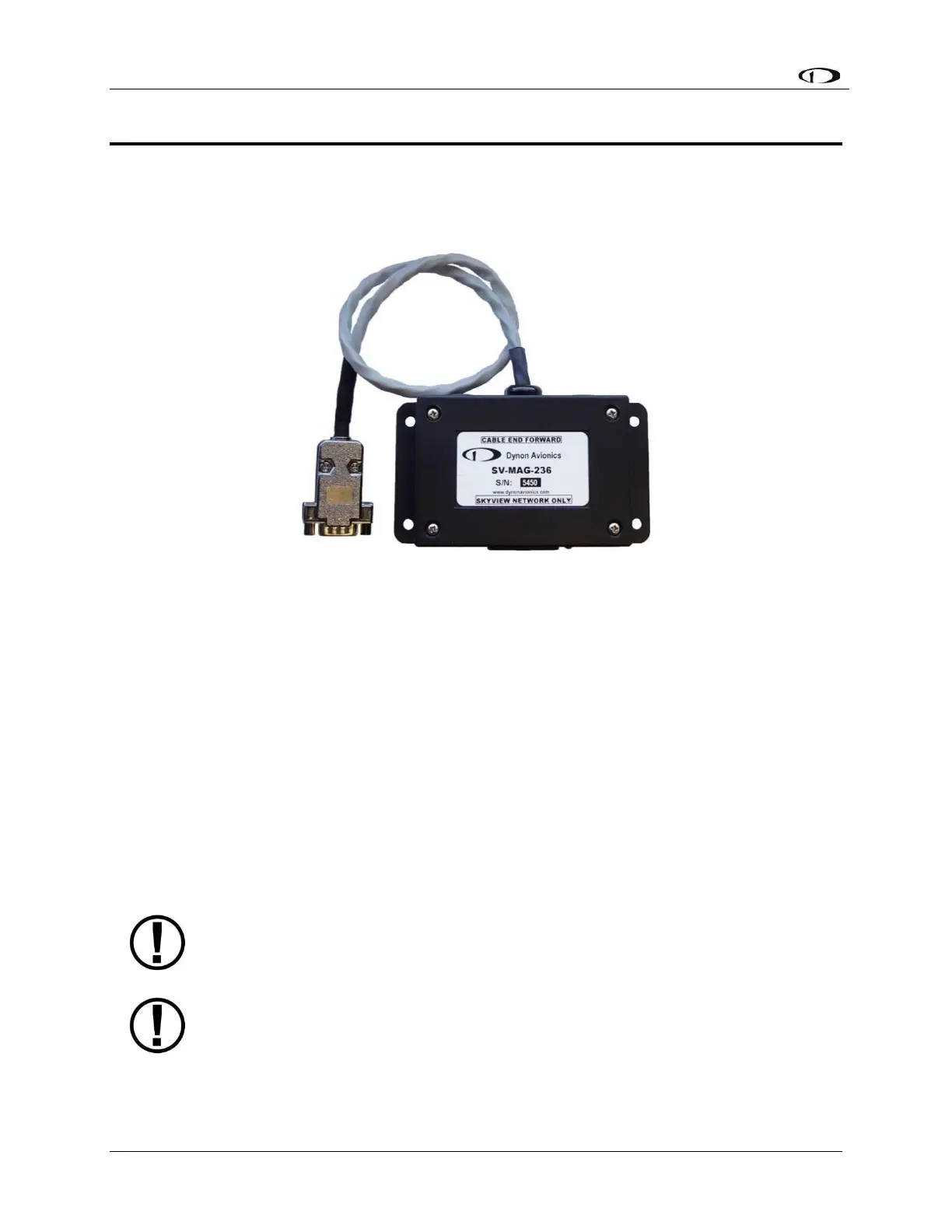

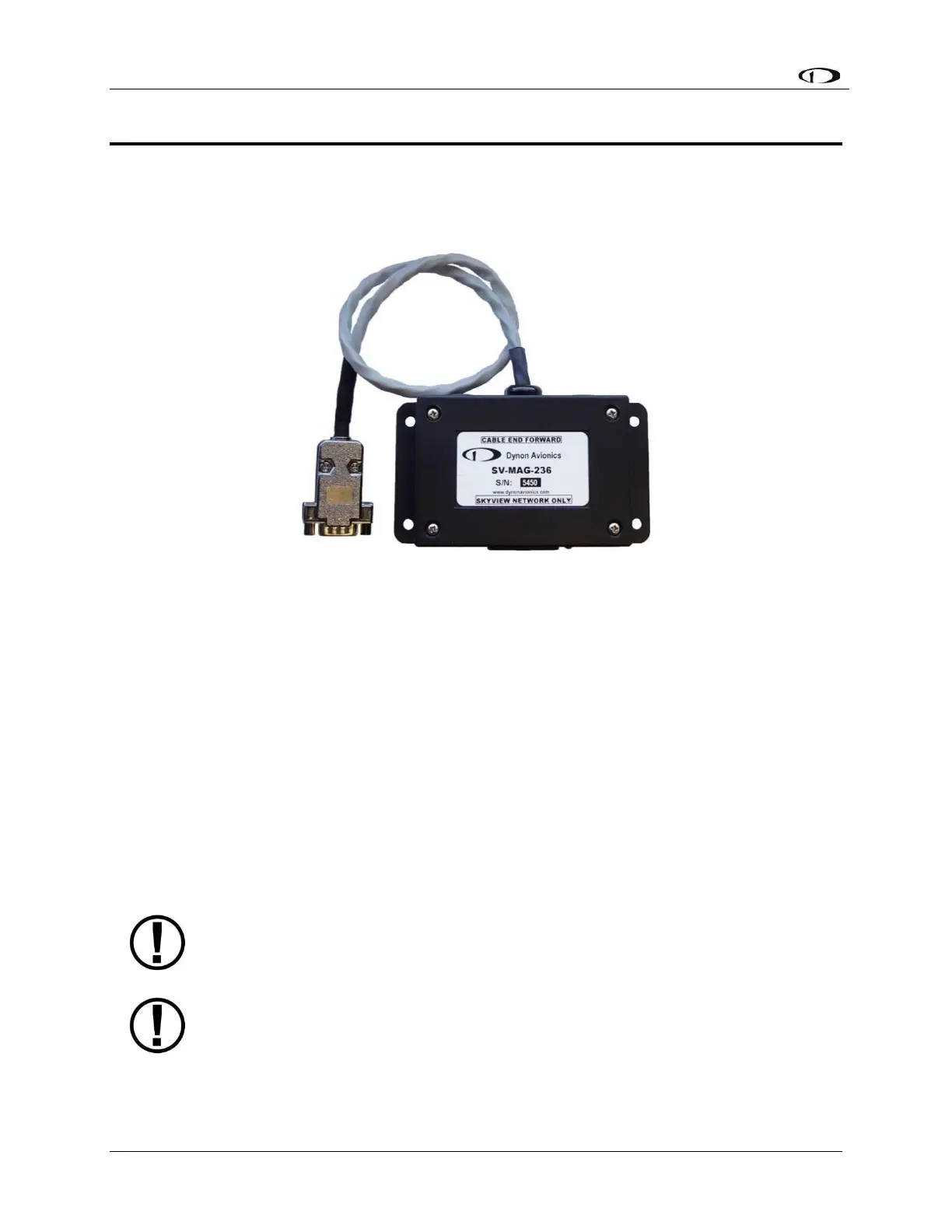

The SV-MAG-236 provides SkyView with the magnetic heading data. To minimize the

possibility of magnetic interference from the connector assembly, the SV-MAG-236 uses

an 18-inch integral cable, so that metal connector is removed from the magnetometer

sensor.

Figure 41: SV-MAG-236 (Photo)

8.1 Mechanical Installation

The most critical factor in the SV-MAG-236 being able to accurately sense magnetic

heading is for it to be installed in an area of the plane that is magnetically benign.

Given that it may be difficult or impossible to avoid all sources of magnetic interference,

it is possible to characterize and compensate for small, static magnetic fields with

calibration. Calibration cannot, however, compensate for dynamic magnetic fields (e.g.,

AC currents, non-constant DC currents, and non-stationary ferrous material such as

electric turn coordinators and control surfaces). Thus, you must avoid mounting the

module close to sources of dynamic magnetic fields, avoid wires that carry large amounts

of current, and use non-magnetic fasteners for installation (see caution below). Dynon

Avionics’ general rule of thumb is that 1 to 2 feet (30.5 cm and 61 cm) between the module

and sources of magnetic fields is generally good enough, but 2 (61 cm) or more feet is

better.

Stainless steel mounting hardware is not always non-magnetic, and thus is

not recommended. The best type of mounting hardware (screws, bolts,

washers, AND nuts) to install the SV-MAG-236 is brass.

If you use a magnet to test whether possible interfering materials are non-

magnetic, do not actually touch the magnet to the material you are testing,

as this contact can cause the material you are testing to become

magnetized.

Loading...

Loading...