Print conveyor unit operation

1/3

5. Operation sequence

56200

56200

Print con veyor un it operation

Print conveyor unit operation

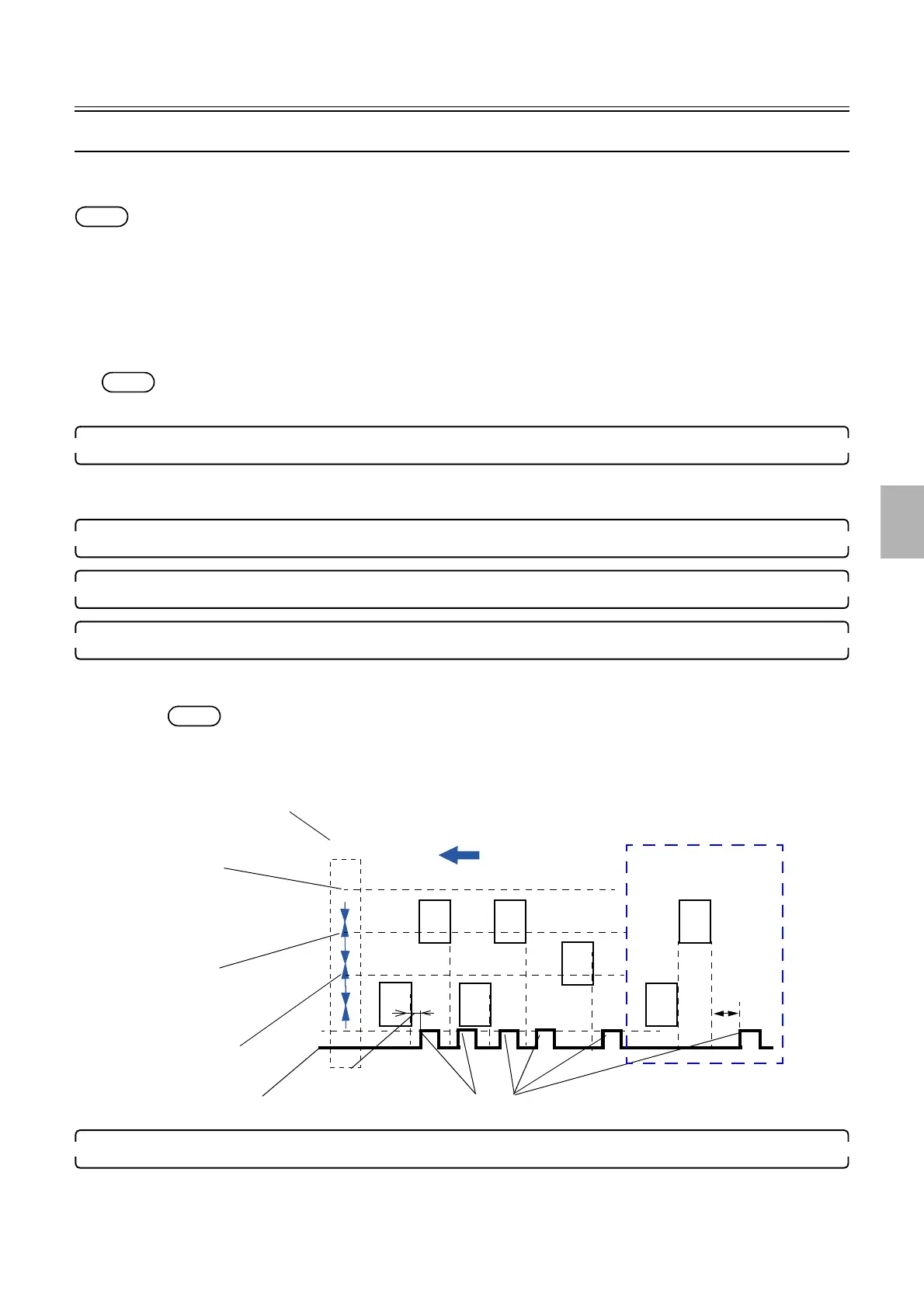

This section explains the process that begins with paper passing through the dryer rack print sensor and ends with it being output to the

print sorter unit.

NOTE

• Print conveyor operation varies depending on differences in paper advance methods brought about by a variety of paper widths and

advance lengths.

•

☞Paper with the width of 152.0 mm or less and the advance length of 178.0 mm or less

•

☞Paper with the width of 152.0 mm or less and the advance length between 178.1 and 305.0 mm

!

!!

! Paper with the width of 152.0 mm or less and the advance length of 178.0 mm or less

NOTE

• For details of paper advance inside the printer, see ☞55500.

1. The paper passes through the print sensor.

• For details of the operation from entering of paper into the processor to the ejection to the print conveyor unit, see

☞56100.

2. The print sensor detects the paper rear end.

3. The prints are output to the print conveyor unit.

4. Conveyor belt starts to move.

• Conveyor motor: ON

Condition: When a specific time passes after

☞2 The print sensor detects the paper rear end.

NOTE

• If the print sensor (right) detects the paper rear end when the print sensor (left) detects the paper during dividing

the paper path into right and left lanes to feed paper, the conveyor unit works after the paper detected by the print

sensor (left) is output to the conveyor unit.

5. Paper is output into the print sorter unit's print receiving tray.

Paper advance direction

Conveyor motor: OFF

A specified time

Conveyor motor: ON

Dryer rack

Print sensor (left)

Print sensor (right)

Print sensor (center)

G085316

Distributed by: minilablaser.com

Loading...

Loading...