10.3.2 Resetting maintenance interval counters

According to the way a machine is equipped, sensors and/or maintenance interval counters moni‐

tor the operational state of important functional devices. Required maintenance work is shown on

SIGMA CONTROL 2 .

Precondition Maintenance performed and

maintenance message acknowledged.

➤ Reset the maintenance interval counter as described in the SIGMA CONTROL 2 operating

manual.

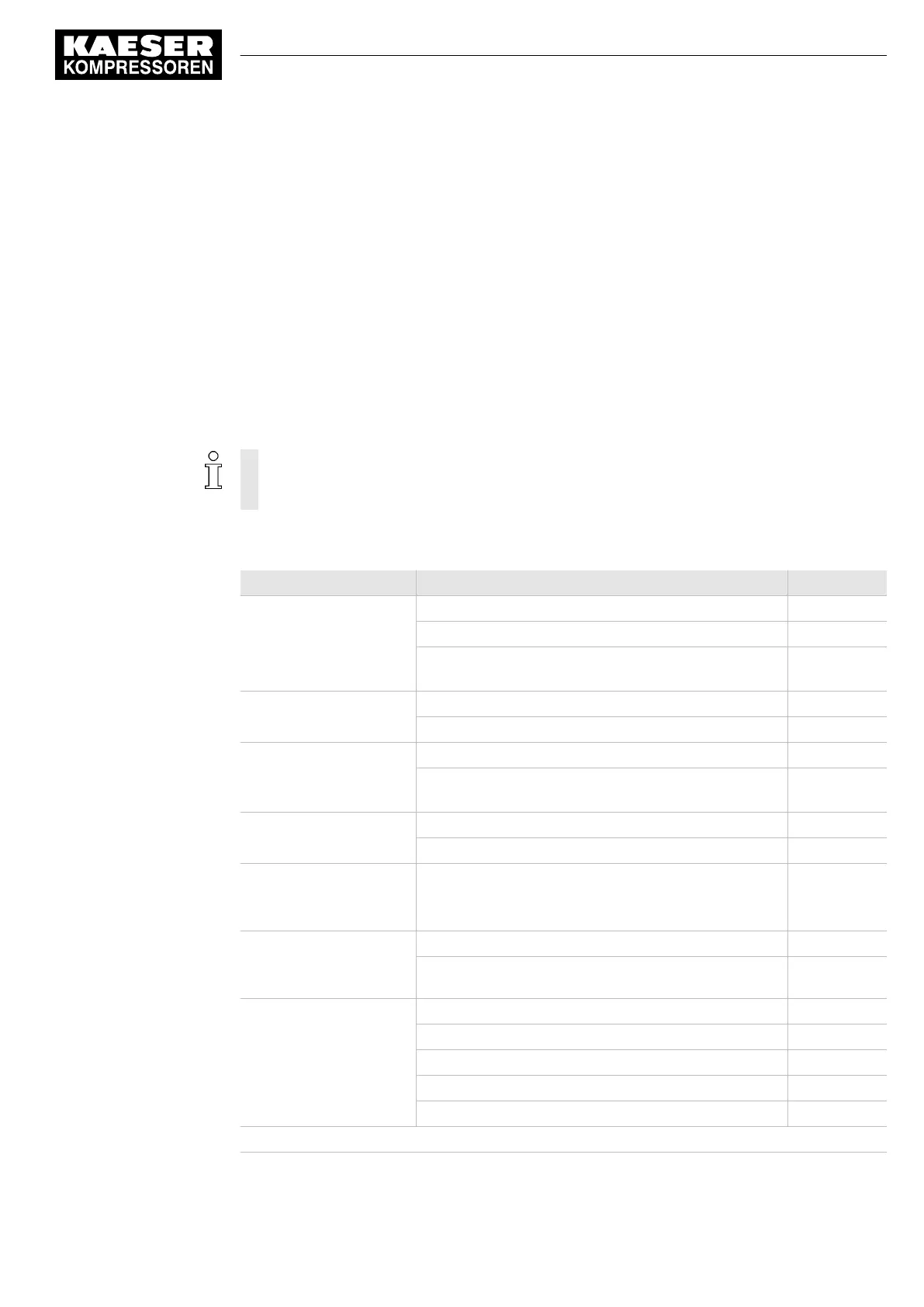

10.3.3 Regular maintenance tasks

The table below lists maintenance tasks required.

The compressor must be evacuated and then filled with gas after commencing any mainte‐

nance or service work requiring an opening of the pressure system.

➤ Detailed information can be found in chapter 7.8.

➤ Take note of the controller's service messages and carry out tasks punctually, taking ambient

and operating conditions into account.

Interval Maintenance task See chapter

weekly Check the cooling oil level. 10.13

Check the oil collecting tank. 10.4

Control cabinet:

Check the filter mat

10.5

Up to 1,000 h Clean the cooler. 10.6

Check the cooling air filter mat 10.8

Up to 8,000 h

At least annually

Change the cooling air filter mat 10.8

Control cabinet:

Change the filter mat.

10.5

Display:

SIGMA CONTROL 2

Maintain the motor bearings. 10.9

Check the coupling. 10.10

Display:

SIGMA CONTROL 2

At least annually

Change the oil filter. 10.17

Display:

SIGMA CONTROL 2

Every 3 years at least

Change the oil separator cartridge. 10.18

Change the cooling oil. 10.16

Annually Check the pressure relief valve. 10.11

Check the overheating safety shutdown function. 10.12

Check the cooler for leaks. 10.6

Maintain the water-cooling system. 10.7

Check that all electrical connections are tight. –

h = operating hours

Tab. 38 Regular maintenance tasks

10 Maintenance

10.3 Following the maintenance plan

ESD_2C_10357405_10–LIN_00 E

Service Manual Screw Compressor

ESD 442/14 bar (abs) SFC SIGMA CONTROL 2

57

Loading...

Loading...