10.19 Assembling flexible pipe connections

With the machine depressurized, the clamping bolts must be freely movable by hand and par‐

allel with the pipe.

All clamping bolts must be equally loaded.

➤ Replace the self-locking nuts.

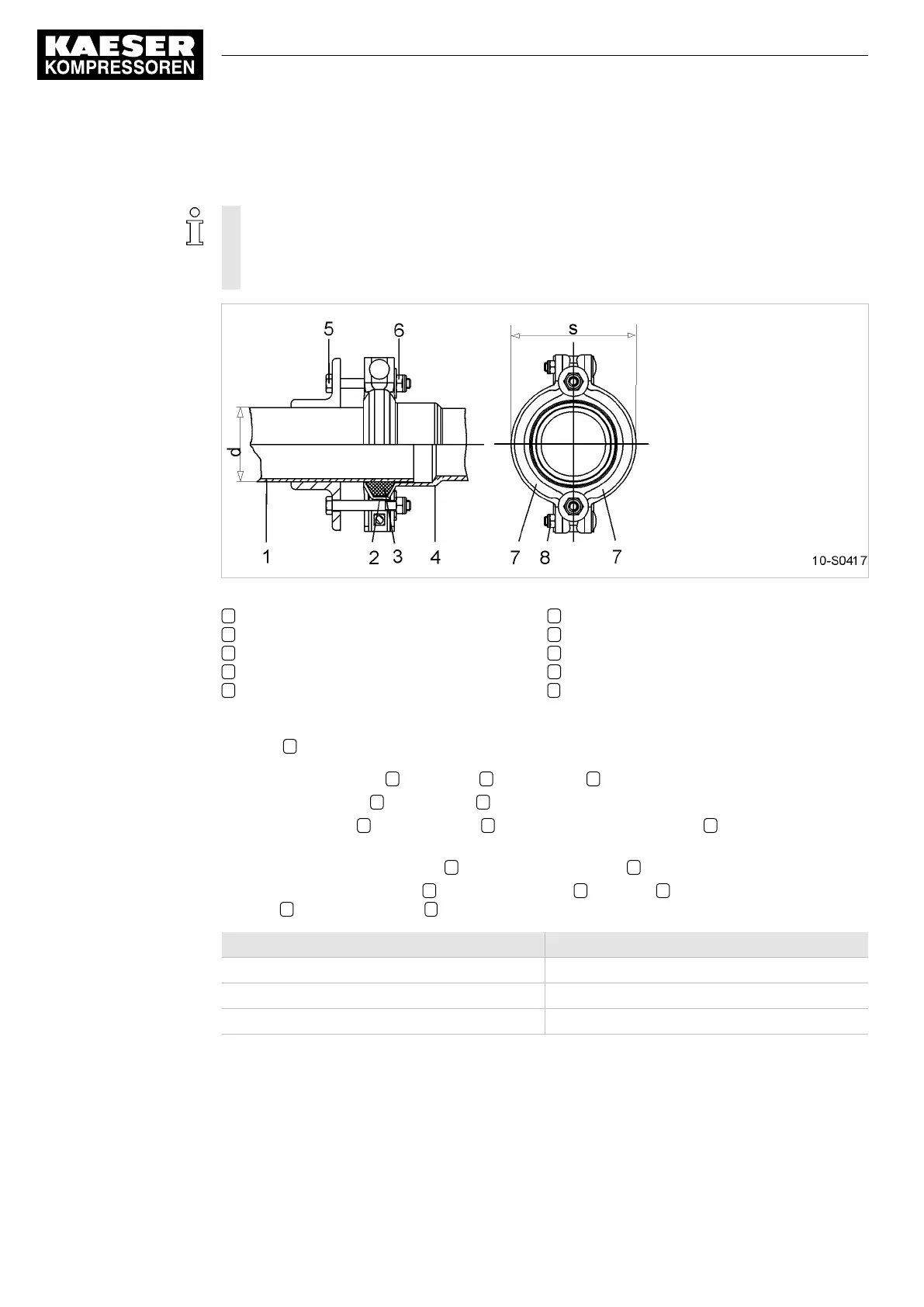

Fig. 37 Assembling flexible pipe connections

1 Pipe

2 Seal holder

3 Seal

4 Sleeve

5 Tensioning bolt

6 Self-locking nut

7 Pipe clamp halves

8 Self-locking nut

d Pipe diameter (outside)

s Dimension of the flexible pipe joint under

tension.

Precondition The pipe 1 must be deburred and the sealing face clean and undamaged.

1. Slide the seal holder 2 and gasket 3 over the pipe 1 .

2. Slide the pipe end 1 into the bush 4 without pretension.

3. Slide the gasket 3 with seal holder 2 up the sealing face of the bush 4 taking care of pipe

alignment.

4. Tighten up the clamping bolts 5 with the self-locking nuts 6 .

5. Lay the pipe clamp halves 7 over the seal holder 2 and bush 4 and tighten the self-locking

nuts 8 until the dimension s is reached.

Pipe diameter: d [mm] Clamp diameter: s [mm]

42.0 83.0 ± 2%

89.0 124.0 ± 2%

114.0 152.0 ± 2%

Tab. 40 Dimensions of the flexible pipe connection

10 Maintenance

10.19 Assembling flexible pipe connections

78

Service Manual Screw Compressor

ESD 442/14 bar (abs) SFC SIGMA CONTROL 2 ESD_2C_10357405_10–LIN_00 E

Loading...

Loading...