When working on the drive system

Touching voltage carrying components can result in electric shocks, burns or death.

Touching the fan wheel, the coupling or the belt drive while the machine is switched on can result

in serious injury.

➤ Switch off and lock out the power supply isolating device and verify the absence of voltage.

➤ Do not open the cabinet while the machine is switched on.

Further information Details of authorized personnel are found in chapter 3.4.2.

Details of dangers and their avoidance are found in chapter 3.5.

6.2 Reporting Transport Damage

1. Check the machine for visible and hidden transport damage.

2. Inform the carrier and the manufacturer in writing of any damage without delay.

6.3 Checking the tightness

For transport and short-term storage, the machine is filled in the factory with gas with an overpres‐

sure of 0.5 bar.

If the machine is de-pressurised prior to installation, a leak test may need to be performed on-site.

➤ Use a manual pressure gauge to measure the gas pressure.

Did the protective gas escape?

➤ Perform leak test. If required, consult with the manufacturer.

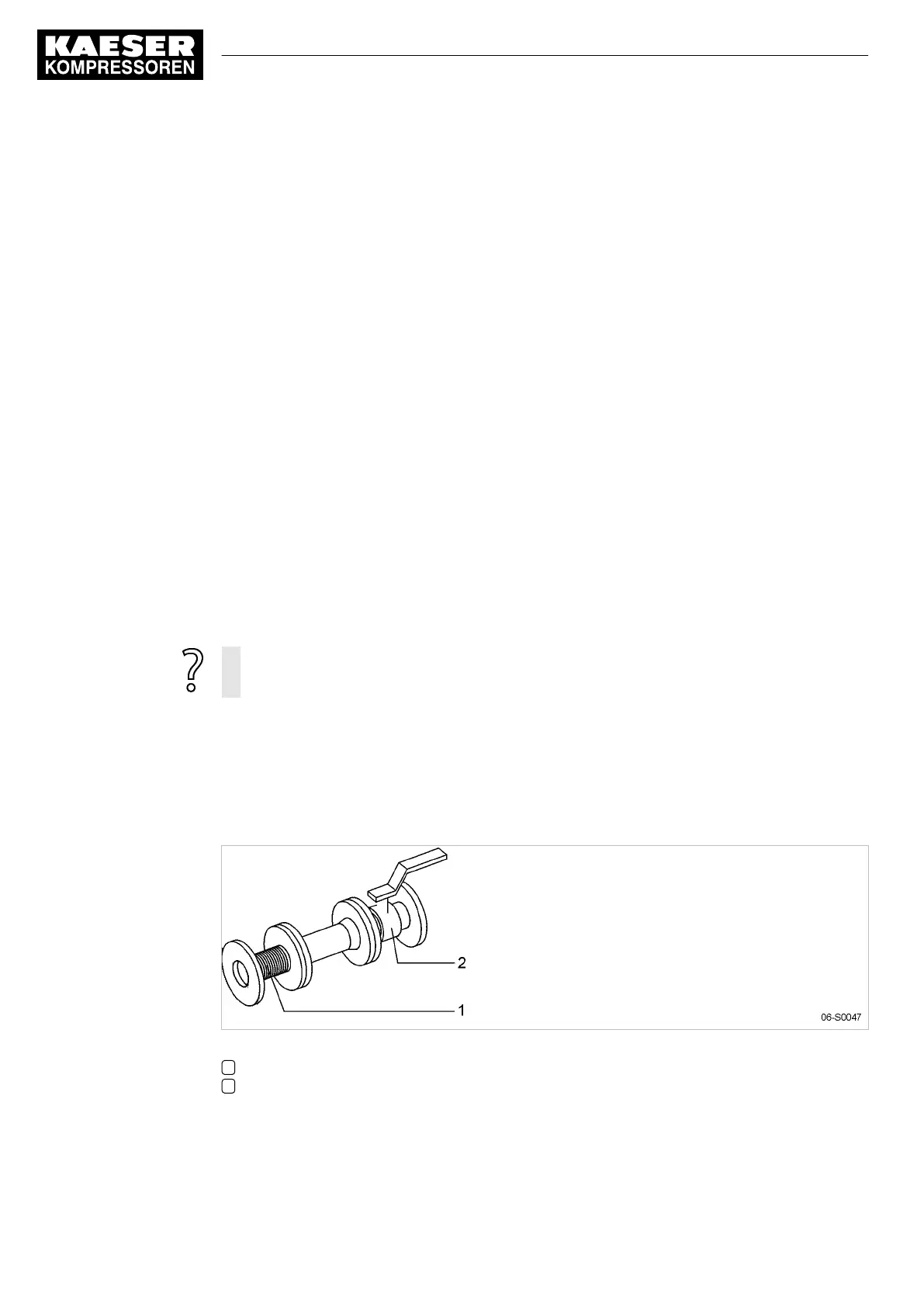

6.4 Installing gas connections

6.4.1 Installing inlet and outlet gas connections

Precondition The gas network and the machine are fully de-pressurised.

Fig. 12 Gas connection

1 Axial compensator or flexible hose

2 Shut-off valve

6 Installation

6.2 Reporting Transport Damage

38

Service Manual Screw Compressor

ESD 442/14 bar (abs) SFC SIGMA CONTROL 2 ESD_2C_10357405_10–LIN_00 E

Loading...

Loading...