DMTA-10004-01EN, Rev. D, November 2016

Chapter 7

94

7.3.1 Steam Boiler Tube Scale

The very high temperatures found inside steam boilers (over 500 °C or 1000 °F) can

cause the formation of magnetite (a specific type of hard and brittle iron oxide), on the

inside and outside surfaces of steel boiler tubes. At very high temperatures, water

vapor reacts with the iron in the steel to form magnetite and hydrogen, according to

the following formula:

3 Fe + 4 H

2

0 = Fe

3

O

4

+ 4 H

2

The speed of this reaction increases with temperature. Oxygen atoms diffuse inward

through the magnetite layer, and iron atoms diffuse outward, so that scale continues

to grow even after the tube surface is completely covered.

Magnetite scale acts as a thermal insulation on the pipe, since the thermal

conductivity of the scale is approximately 3 % of that of steel. When heat no longer

radiates efficiently from the flame through the tube and into the steam within, the

tube wall heats to temperatures beyond intended operating range. Long term

exposure to overly high temperatures, combined with the very high pressure inside

the tube, leads to intergranular micro-cracking in the metal and to creep deformation

(slow swelling or bulging of the metal). This eventually leads to tube failure.

The growth of magnetite scale and associated metal damage are primary limiting

factors for boiler tube service life. The process begins slowly and then accelerates. As

the scale grows thicker, the tube wall becomes hotter, which in turn increases the rate

of both scale growth and metal damage. Studies in the power generation industry

indicate that the effect of scale is relatively insignificant up to thicknesses of

approximately 0.3 mm (0.012 in.). Beyond that thickness, the negative effects of scale

increase rapidly. Measurement of scale thickness allows a plant operator to estimate

remaining tube service life and to identify and replace tubes that are approaching the

failure point. Ultrasonic testing with the 38DL PLUS provides a quick and

nondestructive method for measuring scale.

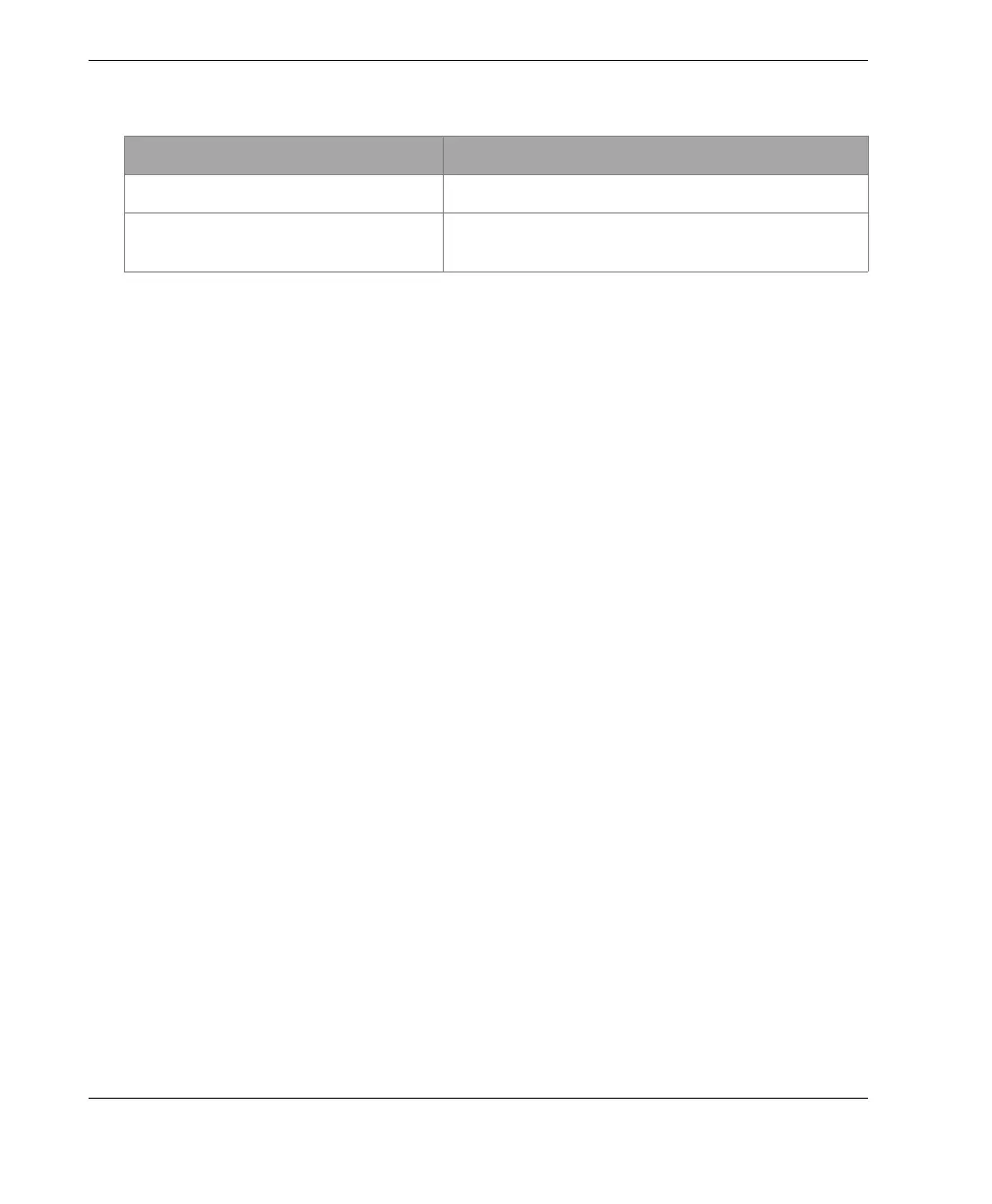

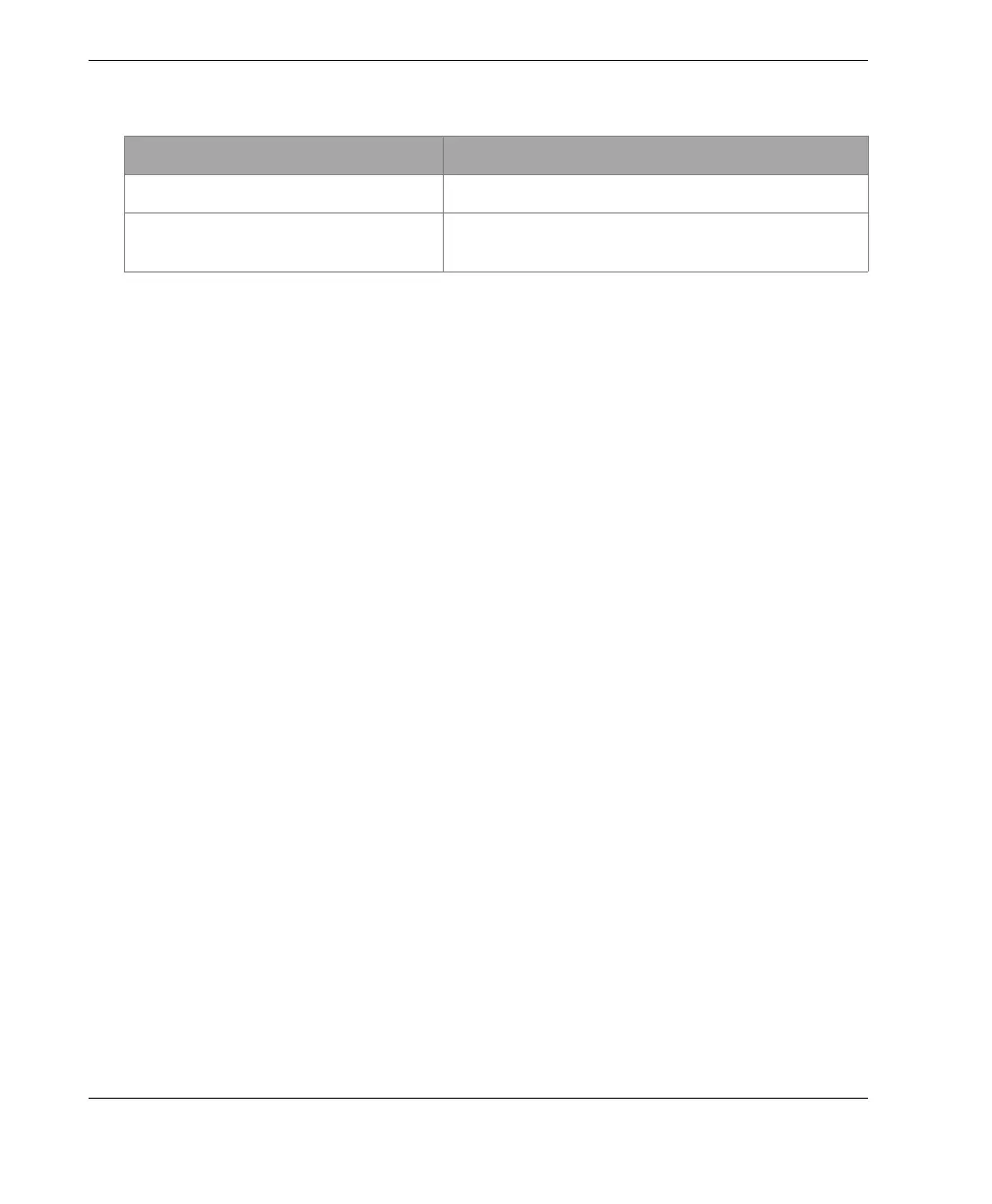

Table 5 Oxide layer transducers

Transducer Minimum internal scale thickness

M2017 [U8415002] 0.254 mm (0.010 in.)

M2091 [U8415018]

normal incident shear

0.152 mm (0.006 in.)

Loading...

Loading...