DMTA-10004-01EN, Rev. D, November 2016

Chapter 7

98

To achieve accurate boiler tube and internal oxide scale thickness readings, remove

any oxide scale or coating from the external surface of the boiler tube.

The minimum internal oxide thickness that the 38DL PLUS can measure depends on

the material sound velocity but is approximately 0.254 mm (0.010 in.) with the M2017

transducer or 0.152 mm (0.006 in.) with the M2091 transducer. The 38DL PLUS only

displays the thickness of the steel boiler tube when the internal oxide scale thickness

is below the minimum measurement capability or when it is exfoliated (disbonded)

from the inside of the boiler tube.

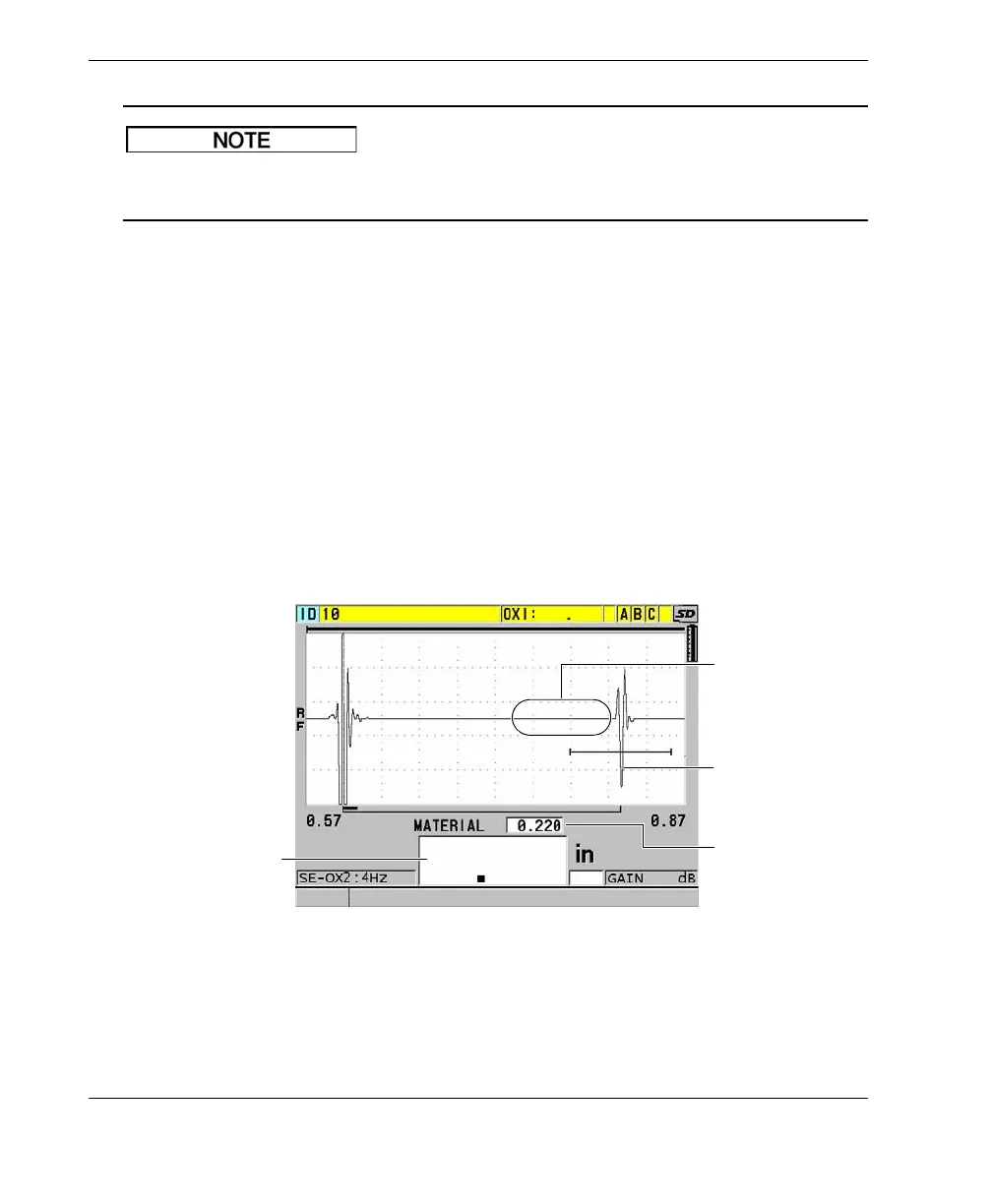

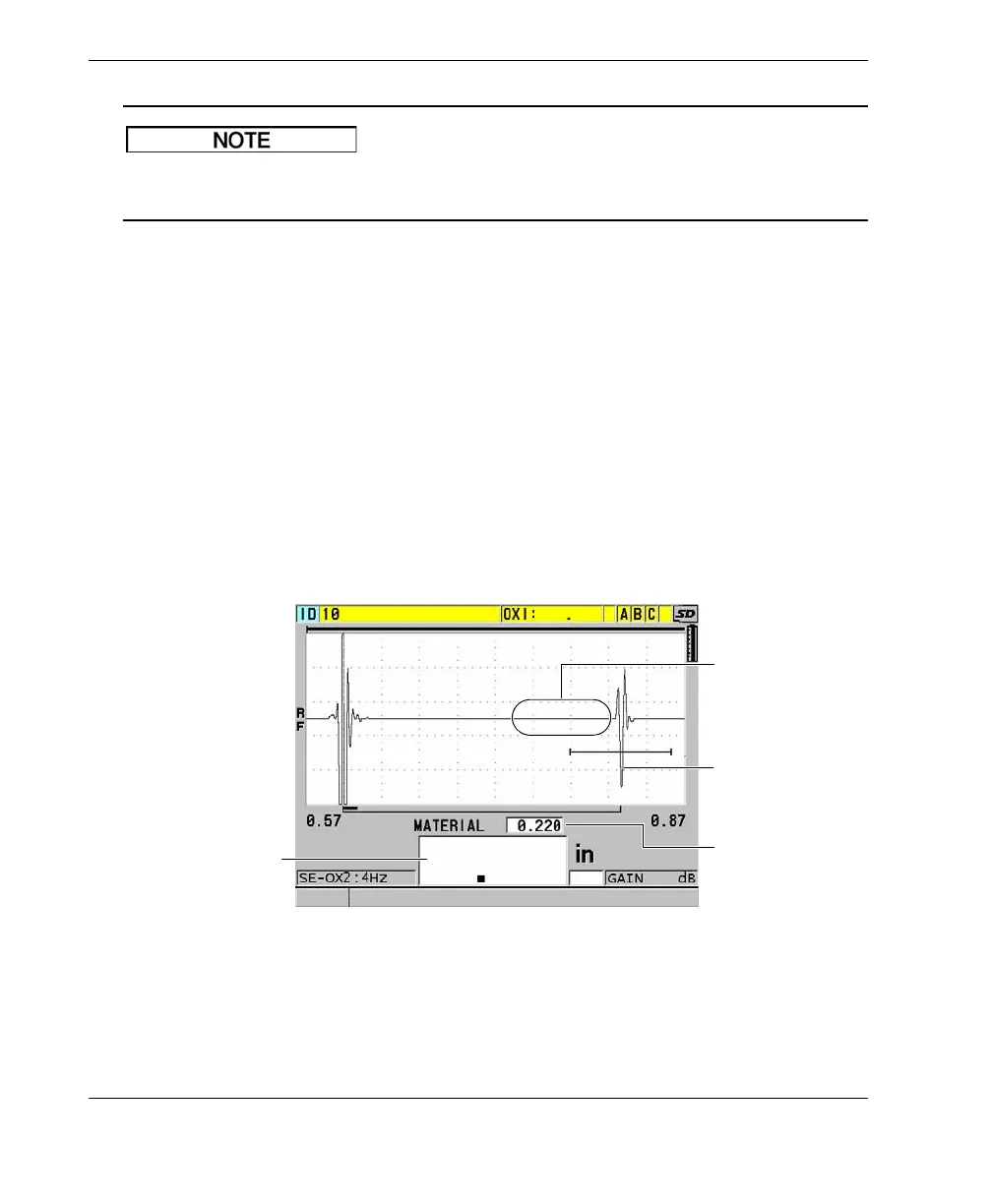

Figure 7-5 on page 98 shows a waveform from a sample in which the internal oxide

layer is disbonded from the boiler tube. Because the oxide is disbonded, sound energy

does not travel into the internal oxide layer, and only a single reflected echo from the

inside of the boiler tube appears. When the internal oxide is thinner than 0.25 mm

(0.010 in.), the waveform looks almost identical. The steel/oxide interface is so close in

time to the echo from the inside of the oxide that it cannot be separated from the total

back-wall echo and will produce a single echo.

Figure 7‑5 Measurement screen for a disbonded oxide layer

Absence of a

steel/oxide echo

Tube thickness

Oxide layer thickness

Single echo from the

inside of boiler tube

Loading...

Loading...