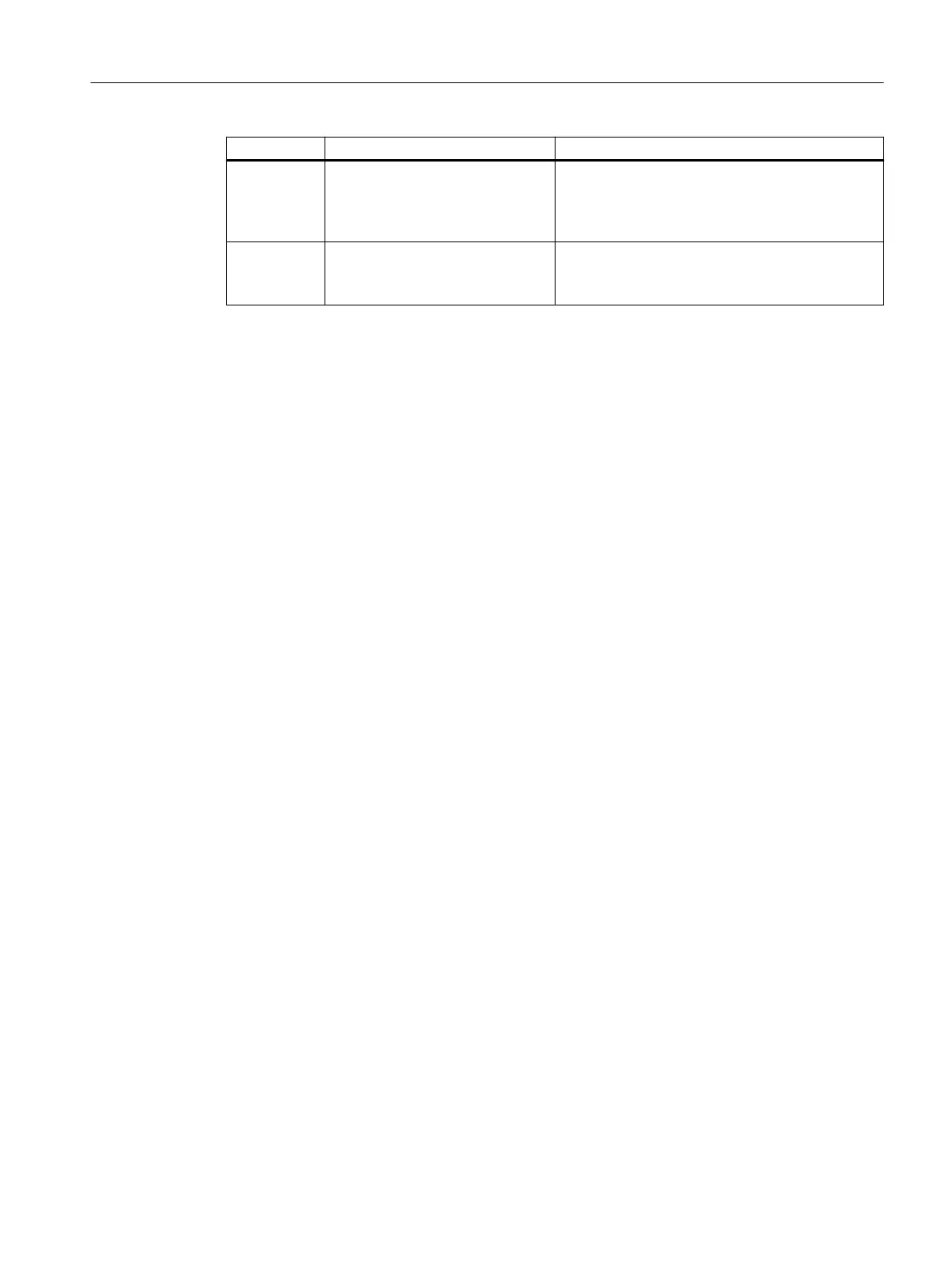

Parameter Description Setting

p1352 CI: Motor holding brake starting

frequency signal source

Sets the signal source for the frequency set value at

the slip compensation output when starting with

motor holding brake.

Factory setting: 1351

p1475 CI: Speed controller torque setting

value for motor holding brake

Sets the signal source for the torque set value when

starting with motor holding brake.

Factory setting: 0

7.12 Encoder Interface

Overview

The SINAMICS G115D inverter has a simple HTL encoder interface where the A and B tracks of

the HTL encoder are read into the inverter via two digital inputs (DI0 and DI1).

The other encoder signals, inverted A and B tracks and zero signals, are not read in or evaluated.

As an alternative to the HTL encoder, one sensor can be connected as a pulse encoder or two

sensors/signals as pulse/direction encoders.

An encoder or sensor connected to the SINAMICS G115D is not used for motor control.

The SINAMICS G115D inverter is only a decentralized encoder interface for a higher-level

controller (PLC).

This means that the encoder signal is acquired in the SINAMICS G115D and the counter value

can be sent to the control system via Pronet with telegram 3 in order to realize positioning

with a technology object.

When using an HTL encoder:

• An HTL encoder can be read in via DI0 and DI1 (A and B track only).

• 2-bit ne resolution

• Pulse multiplication (fourfold)

When using sensors (pulse / direction interface):

• One sensor (pulse) or two sensors / signals (pulse and direction) can be connected

• 2-bit ne resolution

• No pulse multiplication

Specications

Maximum resolution: 2048 pulses/rotation

Maximum HTL frequency: 200 KHz

Maximum permitted cable length for the Encoder: 30 m with shielding.

Advanced commissioning

7.12Encoder Interface

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 229

Loading...

Loading...